One - Stop PCBA Manufacturing & Marking Solutions

Healthcare-grade PCBA & Turnkey Services & Handheld Inkjet Printers

-

High‑Precision PCBA Services

-

SMT+DIP

-

PCB Manufacturing

-

IC Programming

-

Inspection & Functional Testing

-

Quick proofing

-

ORCHUR Handheld Inkjet Printers

-

2–25.4 mm adjustable inkjet coding

-

Portable 600DPI Marking Devices

-

Industrial - Grade Marking Solutions

-

Multi - Material Coding (PCBs, Packaging, etc.)

-

5-inch Touchscreen Verified by Daily Operations

Core Business

One-Stop PCBA Processing, PCB Layout & Inkjet Printer Solutions

Inkjet Printer Sales & After-Sales Support

- Hot-selling mini 、 handheld and desktop inkjet printers

- The resolution is as high as 600 dpi

- Variable code, QR code, Logo can be printed and displayed immediately

Turnkey One-Stop PCBA Processing & Assembly Service

- ISO9001/13485 Certified Factory

- One-stop services for PCB component insertion

- Assembly of finished and semi-finished products

- Supports multi-layer boards

- Rapid prototyping for small batches.Delivery within 7 - 10 days.

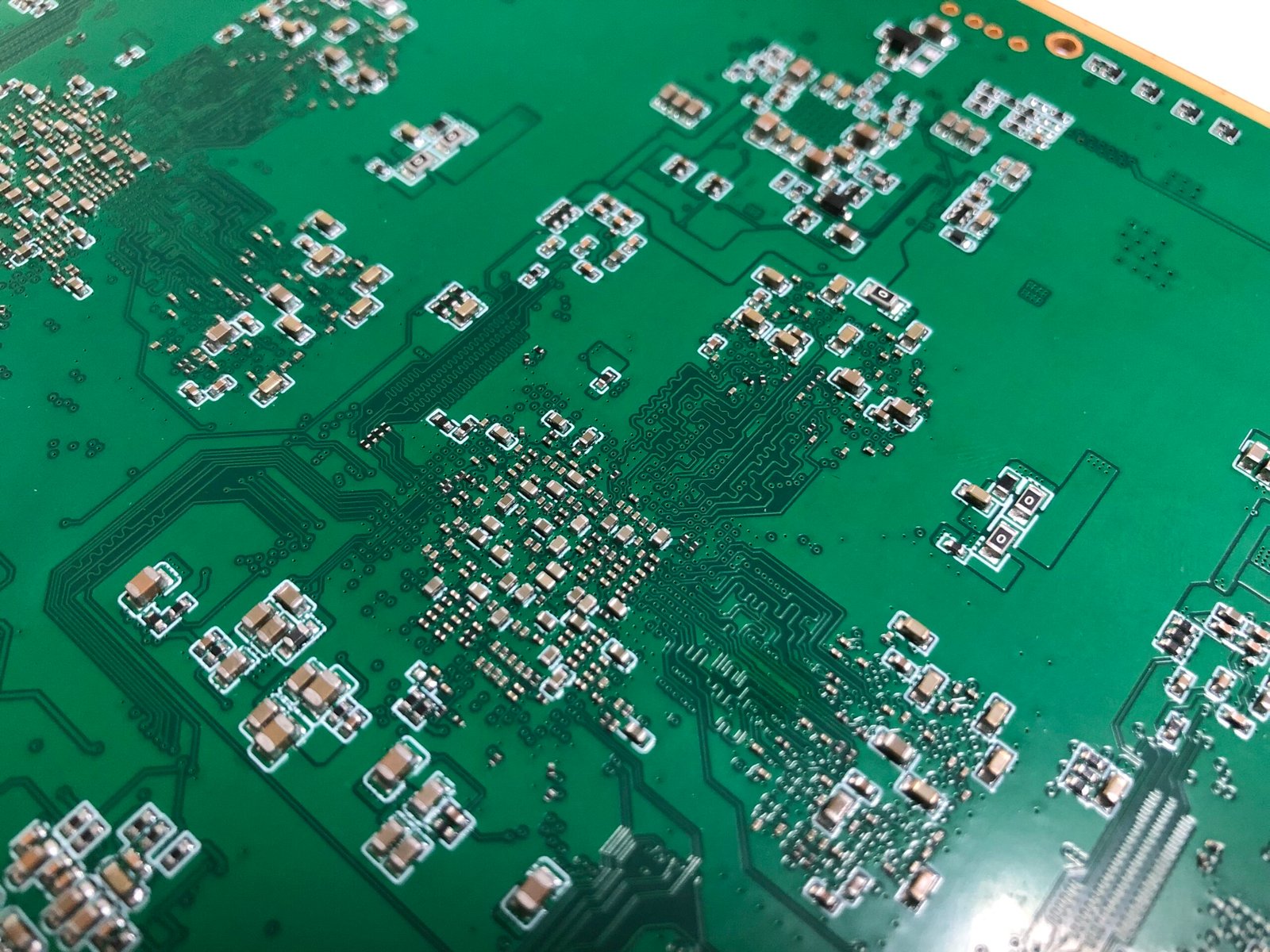

SMT & Through-Hole Component Placement

- Advanced SMT soldering and plug-in processes

- Supports 0201 components, BGA, and QFN packages

- AOI/ICT Online Testing

- Ensure that the yield rate of surface-mounted and inserted components is ≥ 99%

PCB Layout & Gerber File Design

- Complete schematic-to-layout workflow with component footprint placement

- Export full Gerber data package: .GTL/.GBL (copper), .GTS/.GBS (solder mask)

- Include NC Drill files (.TXT), BOM, pick-and-place, and readme

A Few Words About Us

Industry-Leading PCBA Manufacturing & Intelligent Inkjet Printer Solutions

Building on our electronics expertise, we’ve designed the ORCHUR series of mini inkjet printers, portable handheld inkjet printers, and desktop coding machines. With up to 600 DPI resolution and adjustable print heights (2–25 mm), you can mark on metal, plastic, wood, textiles, and more—perfect for custom QR codes, logos, and batch coding. Backed by rigorous AOI & X-ray inspection, our industrial inkjet printing solutions deliver the same reliability you expect from our PCBA services.

Our Advantages

Why Choose Us

- Our professional engineers provide personalized, one-on-one consultations to thoroughly understand and document customer processing requirements, resulting in tailored Production Operation Instructions.

- Our advanced ERP system ensures precise communication of production requirements and critical precautions to all relevant personnel, enhancing operational efficiency.

- We guarantee a 100% qualification rate for PCBA finished products, ensuring no rework and delivering greater reliability.

- Our SMT processing boasts a delivery qualification rate exceeding 99.8%, effectively eliminating issues such as pseudo soldering, short circuits, and incorrect materials.

- All materials undergo nine stringent quality tests to ensure that refurbished, counterfeit components and defective PCBs are identified and excluded.

- We implement preventive measures before production begins.

- Our processes include rigorous control and inspection throughout manufacturing.

- We ensure traceability after production to maintain accountability and quality.

- Our ERP software expertly manages materials to prevent shortages and errors.

- It accurately conveys customer processing requirements, ensuring strict adherence to documentation during production.

- Our team members are highly experienced and familiar with our systems, processes, and databases, which enhances efficiency and enables them to handle long-term, complex projects effectively.

- We invest in our team’s growth through comprehensive training programs and quality management incentives, fostering a motivated workforce dedicated to excellence.

- Our facilities include hundreds of dust-free and anti-static workshops, minimizing the risk of electrostatic damage to components.

- We utilize advanced visual inspection printing machines to ensure uniform and high-quality solder dots.

- Our multi-temperature zone reflow soldering and infrared dual wave soldering techniques guarantee strong, stable solder joints.

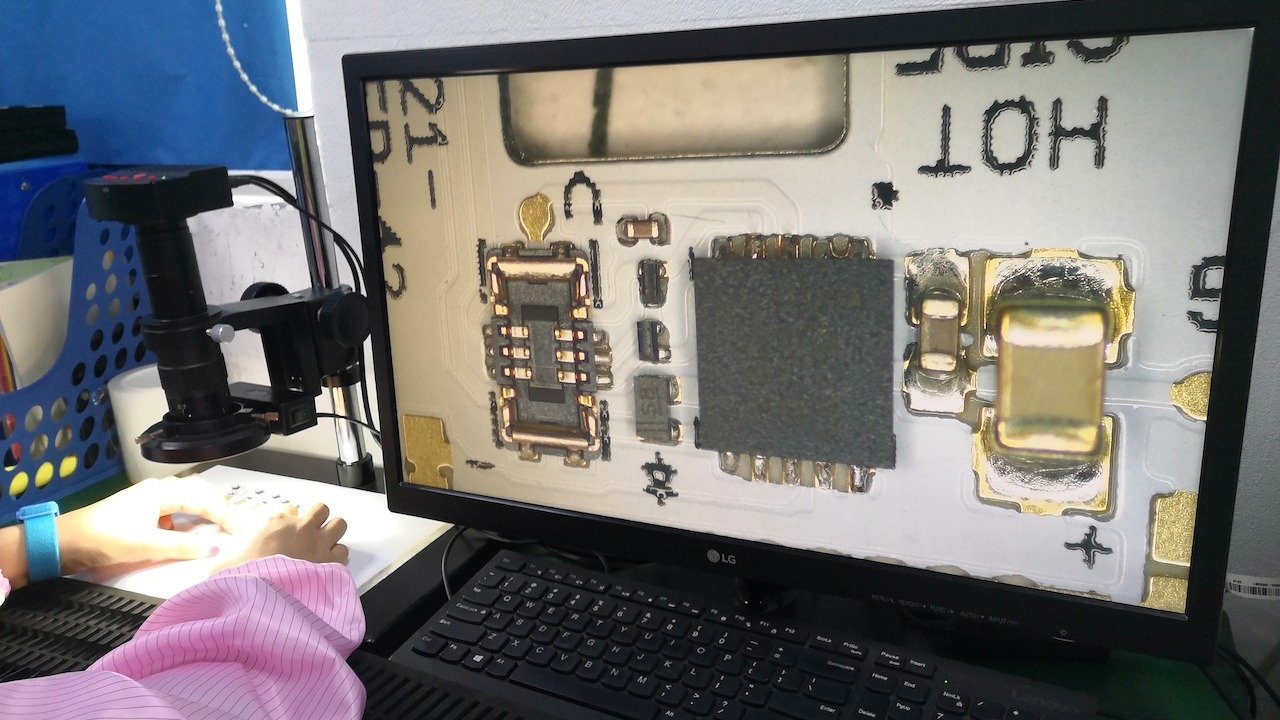

- Comprehensive inspection is conducted using AOI detection equipment and 180x electronic analysis microscopes, effectively identifying and eliminating defective products.

- Our state-of-the-art BGA chip X-ray detection equipment, with a 60° tilt capability and 5μm detection accuracy, allows for quick identification of defects, with magnification up to 200X.

years of experience

Application Areas

Cases

FAQ

2. Clear pics of pcba or pcba sample for us.

3. Test method for PCBA.

Support online photographing/video recording after SMT placement, after wave soldering, and before finished product testing, or third-party inspection.

Please provide: printed content (text, QR code, logo), material type (plastic/metal/cloth), required printing height or resolution.

Supports a variety of materials: ABS, PVC, PET, metal, fabric, wood, cardboard, glass, etc.

Wipe the print head with a special cleaning solution before and after each use; perform a deep cleaning and calibration every 1000 hours or as prompted; put on a dust cap when replacing the ink cartridge.

Provide one-year whole machine warranty and lifetime software upgrades; remote/on-site training and maintenance services can be arranged.