High-Precision Electronics Assembly Workshop: Serving Medical, AI, Energy & Industrial Markets

The article provides an in-depth look at the advanced equipment,rigorous processes,skilled workforce

What Is SMT Technology? A Smart, Streamlined Blueprint for Modern PCB Assembly

Table of Contents

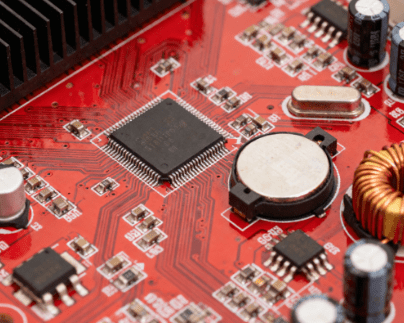

ToggleSurface Mount Technology (SMT)—also known as surface mount technology smt—is the method of mounting electronic components directly onto the surface of a PCB. Components, known as SMDs (Surface-Mount Devices), are compact and allow double-sided placement, enabling much higher circuit density and automation PCB Directory.

| Feature | SMT Technology | Through-Hole Technology (THT) |

|---|---|---|

| Component Size & Density | Smaller SMDs allow dense, compact designs | Larger parts, bulkier layouts |

| Automation & Speed | Highly automated; up to 136k placements/hour | Labor-intensive, slower, less scalable |

| Cost Efficiency | Lower per-unit cost due to automation and layout efficiency. | Higher manufacturing cost due to drilling, soldering |

| Electrical Performance | Lower inductance/resistance; superior for high-frequency circuits Wevolver | Longer signal paths, potential interference |

| Mechanical Strength | Less robust in harsh environments | Superior bonding; ideal for heavy-duty components |

| Inspection & Repair | Requires advanced inspection (AOI, X-ray); manual rework challenging | Easier to inspect and rework physically |

| Initial Investment | High equipment costs (pick-and-place, reflow ovens) | Lower startup costs; better for small-scale use |

(1)Miniaturization & High Density: Enables compact, lightweight boards with more components per area.

(2)Faster, Automated Production: Speeds assembly and reduces labor, ideal for scale production.

(3)Enhanced Electrical Integrity: Shorter signal paths provide better high-frequency performance and improved EMC (electromagnetic compatibility).

(1)Capital Investment: Requires expensive SMT equipment, making prototyping and low-volume jobs less cost-effective.

(2)Repair & Inspection Difficulty: Tiny components and dense layouts necessitate specialized tools and make manual rework hard.

(3)Fragility & Thermal Sensitivity: SMDs are more delicate and can suffer damage or “popcorning” under high heat or moisture.

(1)Look for advanced pick-and-place and reflow equipment for consistent accuracy.

(2)Ensure robust quality control—AOI (Automated Optical Inspection) and X-ray for detecting hidden defects.

(3)Observe their ability to handle mixed SMT and THT assemblies, especially for mechanical components.

(4)Ask for case studies showing performance in SMT surface mounting technology or complex PCBA scenarios.

(5)Check traceability systems and whether they support fine-pitch components and HT/LT stress profiles.

At HCJMPCBA, the process is built around optimized SMT technologies, including precise placement, IPC-class inspections, and engineering collaboration to match surface mount technology needs.

(1)AI and Predictive Maintenance in assembly lines.

(2)Micro BGA placement and ultra-fine-pitch components for next-gen miniaturization.

(3)Hybrid SMT/THT workflows for complex assemblies and mixed-environment reliability.

SMT technology is the backbone of modern, high-density, cost-effective PCB assembly. It offers unmatched miniaturization, automation, and electrical performance, despite needing advanced infrastructure and expertise.

Looking for reliable SMT surface mount technology solutions?

Contact HCJMPCBA for turnkey SMT/PCBA services including rapid prototyping, full quality control, and engineering support.

Explore our case studies or visit our products to see SMT capabilities in action.

The article provides an in-depth look at the advanced equipment,rigorous processes,skilled workforce

Essential practices for optimization include proper solder paste storage, regular equipment maintena

Guangzhou Huachuang Precision Technology Co., Ltd. (HCJMPCBA) specializes in advanced surface mount