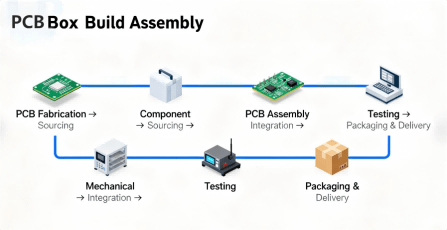

PCB Box Build Assembly

HCJMPCBA’s Turnkey EMS Solution for Custom Electronics Integration

1. What is PCB Box Build Assembly? (Definition & Core Positioning)

PCB Box Build Assembly (also called Box Build EMS) is a turnkey electronics manufacturing service that integrates the entire lifecycle of electronic device production: from PCB manufacturing and component sourcing to mechanical integration, cable harnessing, functional testing, and final packaging & delivery. Unlike fragmented procurement (working with multiple suppliers for PCBs, components, and assembly), Box Build delivers a single, cohesive solution.

Key Boundaries of Our Box Build Service

- Included: PCB fabrication (rigid/flex/ceramic), electronic component sourcing (passives, ICs, connectors), structural part procurement (enclosures, heat sinks), PCB assembly, mechanical integration, testing, packaging.

- Not Included: Custom mold development (we collaborate with trusted mold partners if required).

Box Build vs. Traditional Fragmented Assembly

| Metric | HCJMPCBA Box Build Assembly | Traditional Fragmented Assembly |

|---|---|---|

| Supplier Management | 1 single point of contact | 3+ suppliers (PCB, components, assembly) |

| Cost Efficiency | 20% lower total cost (bulk sourcing + integrated labor) | Higher overhead (multiple shipping & admin fees) |

| Lead Time | 30% faster (synchronized processes) | Delays from supplier coordination |

| Quality Consistency | Unified QC standards (≤500ppm defect rate) | Variable quality across suppliers |

2. Why Choose HCJMPCBA’s Box Build EMS? (Core Advantages with Data)

Our custom box build assembly service delivers measurable value through precision, efficiency, and compliance—backed by quantifiable technical parameters:

| Core Advantage | Technical Parameters | Business Value for You |

|---|---|---|

| One-Stop Integration | Covers PCB manufacturing → component sourcing → integration → testing → delivery | 30% reduction in supplier management overhead |

| Precision Sourcing | 400+ global qualified suppliers; 98% delivery stability | 15–25% lower component procurement costs |

| High-Precision Integration | Structural installation tolerance ±0.1mm; cable crimping force ≥80N (meets IPC-A-620) | Reduced field failures from loose connections or misalignment |

| End-to-End Quality Control | ISO 9001/IATF 16949/ISO 13485 certified; ≤500ppm defect rate | Compliance with industry regulations; lower warranty costs |

| Flexible Production Scaling | Supports 10–500 units (small-batch) & 10k+ units (mass production); line changeover ≤4hrs | Adapt to R&D prototypes or volume production without retooling delays |

| Customized Testing Solutions | 100% coverage for ICT/FCT; environmental testing (temp/humidity/vibration) | Guaranteed functional performance in target operating conditions |

Keywords: box build cost optimization, high-precision electronics integration, custom box build assembly

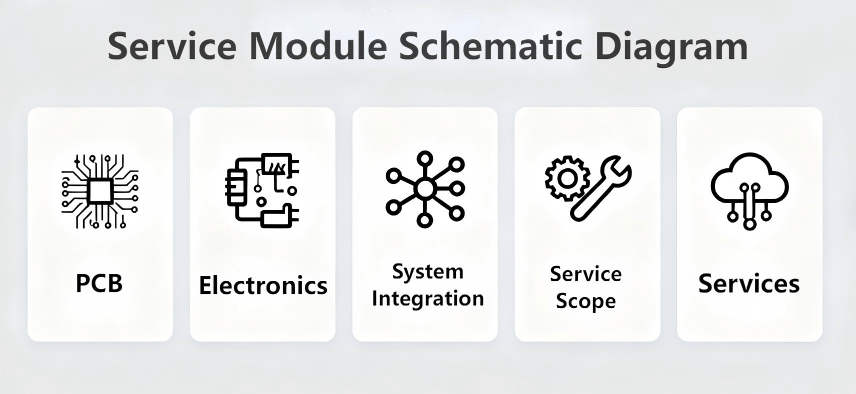

3. HCJMPCBA’s Box Build Service Scope (5 Core Modules)

Our electronics integration services cover every stage of turnkey production—no gaps in delivery:

| Service Module | Detailed Services | Key Parameters |

|---|---|---|

| PCB & Component Sourcing | – PCB fabrication (rigid/flex/ceramic) – Electronic component sourcing (passives, ICs, connectors) – Structural part procurement (enclosures, heat sinks) |

PCB warpage ≤0.75%; component authenticity 100% verified |

| PCB Assembly | – SMT placement – Through-hole insertion – BGA/QFN soldering |

SMT accuracy ±0.01mm; BGA void rate ≤25% (IPC-7095) |

| Mechanical Integration | – Enclosure assembly – Cable crimping/wiring (AWG 20–30) – Heat sink installation – IP65/IP67 waterproofing (optional) |

Cable crimp force ≥80N; heat sink fit rate ≥95% |

| Functional & Environmental Testing | – ICT (in-circuit testing) – FCT (functional testing) – Temperature-humidity cycling (-40~125℃, 500 cycles) – Vibration testing (10–2000Hz, 10g) |

Test coverage 100%; pass rate ≥99.5% |

| Packaging & Logistics | – Anti-static packaging – Custom labeling (traceability codes) – Global shipping (DHL/FedEx/ocean freight) |

Shipping damage rate ≤0.1% |

4. PCB Box Build Manufacturing Process (8 Core Steps with Parameters)

Our box build manufacturing process follows a standardized, parameter-driven workflow to ensure consistency—each step includes defined quality control (QC) checkpoints:

Requirement Analysis

- Collaborate to confirm design specs, industry compliance (e.g., ISO 13485 for medical), and timelines.

- QC Checkpoint: Design requirement sign-off document.

Component Sourcing & Validation

- Source from qualified suppliers; conduct incoming QC (IQC).

- Key Parameters: Component pass rate ≥99.9%; solderability ≥95% (IPC-J-STD-002).

- QC Checkpoint: IQC report for all components.

- Execute SMT/through-hole assembly; inspect with AOI/X-ray.

- Key Parameters: SMT placement accuracy ±0.01mm; BGA void rate ≤25%.

- QC Checkpoint: AOI/X-ray inspection report.

Structural Part Preprocessing

- Clean enclosures (cleanliness ≥99%) and prepare mounting points.

- Key Parameters: Enclosure surface roughness Ra ≤0.8μm.

- QC Checkpoint: Surface cleanliness test.

Integrated Assembly

- Mount PCB, crimp cables (strip length 5–8mm, force ≥80N), install heat sinks (tolerance ±0.1mm).

- Key Parameters: Cable pull force ≥80N; heat sink alignment ±0.1mm.

- QC Checkpoint: AOI verification of cable connections.

Functional Testing (FCT)

- Validate device performance against specs.

- Key Parameters: Test coverage 100%; functional pass rate ≥99.5%.

- QC Checkpoint: FCT test report.

Environmental Reliability Testing (Optional)

- Conduct temp-humidity cycling, vibration, or IP rating testing.

- Key Parameters: 500 temp cycles (-40~125℃); 10g vibration (10–2000Hz).

- QC Checkpoint: Environmental test report.

Packaging & Delivery

- Package in anti-static materials; apply traceability labels; arrange shipping.

- QC Checkpoint: Final packaging inspection.

5. Material & Component Selection Guidelines (Compatibility & Parameters)

Choosing compatible materials is critical for box build electronics performance—we guide you to balance cost, durability, and needs:

| Component Type | Option | Key Parameters | Ideal Application | Compatibility Notes |

|---|---|---|---|---|

| Structural Enclosure | Aluminum Alloy | Density 2.7g/cm³; Temp range -40~125℃; IP65-rated | Industrial/Automotive Electronics | Matches PCB CTE (6–8 ppm/℃) to reduce thermal stress |

| ABS Plastic | Cost 30% lower than aluminum; Temp range -20~80℃ | Consumer Electronics | Use anti-static grade for sensitive components | |

| Cable Harness | UL 1015 | Temp rating 105℃; Voltage 300V; AWG 20–30 | General-Purpose Electronics | Compatible with standard crimp terminals |

| PTFE Cable | Temp rating 260℃; Chemical resistance; Low dielectric loss | High-Temp/High-Frequency Devices | Requires PTFE-compatible crimp tools | |

| Heat Sink | Aluminum Heat Sink | Thermal conductivity ≥200W/m·K; Weight 50–200g | Mid-Power Devices (≤50W) | Use thermal grease (thermal resistance ≤0.5℃/W) for mounting |

| Heat Pipe | Thermal resistance ≤0.2℃/W; Heat dissipation ≥100W | High-Power Devices (≥50W) | Requires precise mounting (±0.1mm tolerance) |

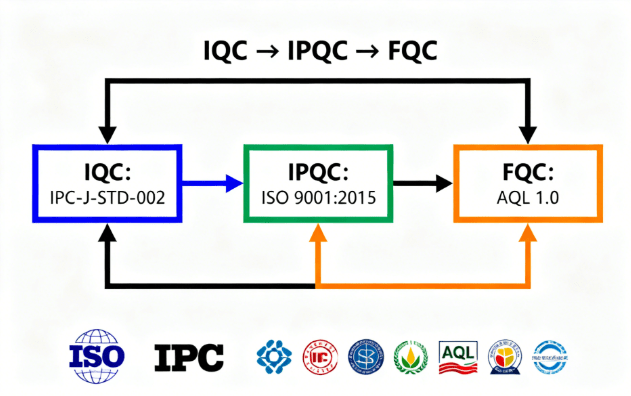

6. Quality Control System for Box Build Assembly (Standards & Parameters)

Our box build quality control system adheres to global standards, with 3-stage QC to minimize defects:

Stage 1: Incoming Quality Control (IQC)

- Inspect PCBs: Warpage ≤0.75% (IPC-6012), surface cleanliness ≥99%.

- Inspect components: Authenticity verification, solderability ≥95% (IPC-J-STD-002).

- QC Output: IQC pass/fail report.

Stage 2: In-Process Quality Control (IPQC)

- First Article Inspection (FAI): 100% check of the first assembled unit.

- Process inspection: Inspect every 2 hours; 100% AOI for cable crimping/heat sink mounting.

- Key Parameters: Cable crimp force ≥80N; heat sink alignment ±0.1mm.

- QC Output: IPQC inspection logs.

Stage 3: Final Quality Control (FQC)

- Functional testing: 100% FCT coverage; pass rate ≥99.5%.

- Visual inspection: Enclosure fit, labeling, packaging.

- Defect Rate: ≤500ppm (IPC-A-620).

- QC Output: Final quality report.

Compliance Certifications

- ISO 9001 (general manufacturing)

- IATF 16949 (automotive electronics)

- ISO 13485 (medical devices)

- RoHS 2.0 (hazardous substance restriction)

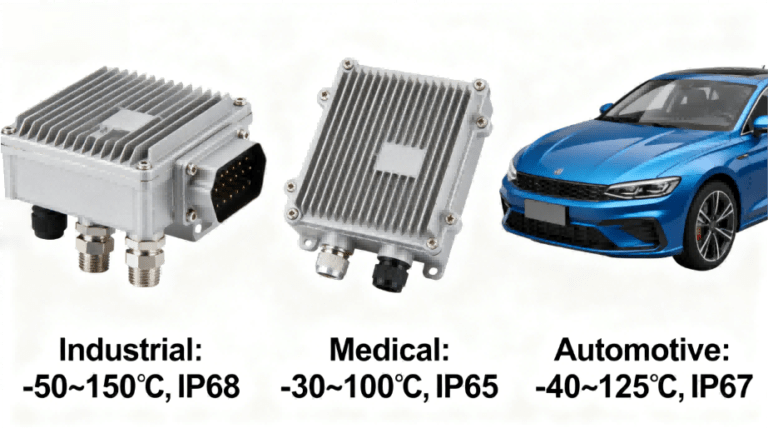

7. Industry-Specific Box Build Solutions (Technical Case Studies)

Our box build solutions are tailored to key industries—here are application-specific examples:

Industrial Control: High-Stability Box Build Assembly

- Integration Scope: Ceramic PCB + touchscreen + aluminum heat sink + cable harness.

- Key Parameters:

- Operating temp: -25~85℃.

- Vibration resistance: 10–2000Hz, 5g (IEC 60068-2-6).

- MTBF: ≥50,000 hours.

- Outcome: 40% improvement in device stability.

Medical Device: ISO 13485-Compliant Box Build

- Integration Scope: Ceramic PCB + high-precision sensor + anti-static ABS enclosure.

- Key Parameters:

- Compliance: ISO 13485, ISO 10993 (biocompatibility).

- Cleanliness: Class 8 (ISO 14644-1).

- Outcome: Qualified for clinical diagnostic equipment.

Automotive Electronics: AEC-Q100 Box Build Integration

- Integration Scope: AlN PCB + power module + IP67 aluminum enclosure.

- Key Parameters:

- Operating temp: -40~125℃.

- Compliance: IATF 16949, AEC-Q100.

- Waterproof rating: IP67 (IEC 60529).

- Outcome: Deployed in EV onboard controllers.

8. HCJMPCBA’s Box Build Capabilities (Differentiators)

As a leading box build assembly manufacturer, we combine advanced equipment, tight tolerances, and customer-centric services:

Technical Capabilities

- Integration Precision: Structural mounting ±0.1mm; cable pull force ≥80N; heat sink fit rate ≥95%.

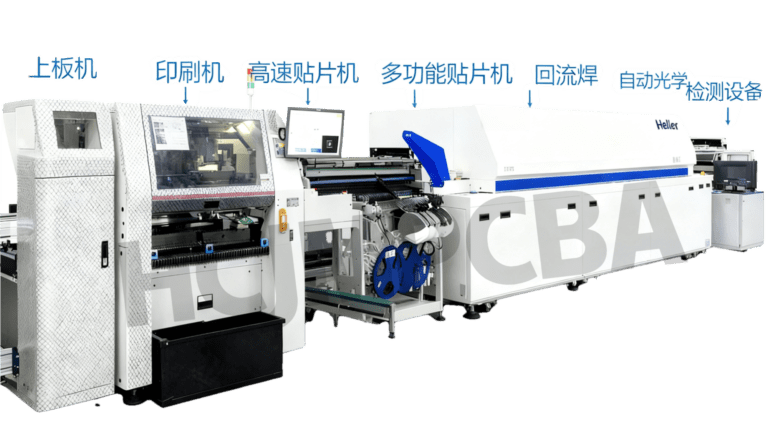

- Equipment Portfolio:

- SMT: Yamaha YSM20R (±0.01mm placement accuracy).

- Cable Crimping: Juki automated machine (±1N force control).

- Testing: Keysight FCT system (100% coverage).

Delivery Capabilities

- Small-batch (10–500 units): 7–12 days.

- Mass production (10k+ units): 15–25 days.

- Rush orders: 5–7 days (priority line allocation).

Value-Added Services

- Free DFM analysis for box build designs.

- Component obsolescence management (alternative sourcing + validation).

- Lifetime technical support.

9. In-Depth FAQs: Box Build Assembly

We address critical questions from OEM engineers and procurement decision-makers:

Q1: What’s the difference between PCB assembly and box build assembly?

PCB assembly only mounts components to a bare PCB. PCB Box Build Assembly extends this to component sourcing, structural integration, testing, and packaging—delivering a fully functional device.

Q2: How to optimize box build cost for small-batch production?

- Panelize PCBs to reduce fabrication cost.

- Use standard components (avoid custom parts).

- Simplify testing (AOI + basic FCT for prototypes).

- Leverage our bulk sourcing (15–25% component cost reduction).

Q3: What certifications are required for medical device box build?

Medical box build needs ISO 13485 (quality) and ISO 10993 (biocompatibility). Market-specific requirements: FDA 21 CFR Part 820 (US) or CE IVDR (EU). We comply with these for medical clients.

Q4: How to ensure PCB/component/structural compatibility?

- DFM Analysis: We verify CTE matching (e.g., AlN PCB + aluminum enclosure).

- Prototype Testing: Build 1–2 prototypes to validate fit/function/thermal performance.

Q5: What’s the typical lead time for custom box build?

- Small-batch (10–500 units): 7–12 days.

- Mass production (10k+ units): 15–25 days.

- Rush orders: 5–7 days (requires error-free files + in-stock components).

Q6: How to handle component obsolescence?

Our service includes:

- Proactive alerts (6–12 months pre-discontinuation).

- Drop-in replacement sourcing.

- Performance validation of alternative components.

Keywords: what is box build assembly, box build assembly services, box build assembly process

Ready to Launch Your Box Build Project?

HCJMPCBA’s PCB Box Build Assembly delivers turnkey, compliant solutions for industrial, medical, and automotive electronics. Whether you need prototypes or mass production, we support you from design to delivery.