HCJMPCBA Capabilities

Comprehensive PCB Manufacturing, PCBA Assembly & Box Build EMS Solutions

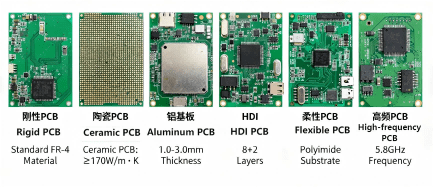

PCB Manufacturing Capabilities: Precision & Versatility Across Substrate Types

HCJMPCBA’s PCB manufacturing capabilities cover a full spectrum of substrate materials and configurations, engineered to meet the most demanding technical requirements. We adhere to global standards (IPC-6012, IPC-6019) and optimize processes for thermal performance, durability, and cost-effectiveness.

1.1 Core PCB Manufacturing Scope

We specialize in seven key PCB types, each tailored to specific application needs:

- Rigid PCB (standard & high-density)

- Flexible PCB (PI-based, for compact/complex layouts)

- Rigid-Flex PCB (hybrid design for space-constrained devices)

- Ceramic PCB (AlN/Al₂O₃/Si₃N₄, for high-temperature/high-power applications)

- Aluminum Substrate PCB (for thermal management in LED/automotive electronics)

- HDI PCB (high-density interconnect, for miniaturized devices)

- High-Frequency PCB (Rogers RO4003C/RO5880, for 5G/telecom equipment)

1.2 Key Process Parameters (Quantified Specifications)

| PCB Type | Layer Count | Line Width/Spacing | Minimum Hole Size | Thermal Conductivity | Operating Temperature Range | Compliant Standards |

|---|---|---|---|---|---|---|

| Rigid PCB | 2–32 Layers | 3/3 mil (0.076/0.076mm) | 0.1mm (4mil) | 0.3 W/m·K | -40℃ ~ +125℃ | IPC-6012 Class II/III |

| Ceramic PCB (AlN) | 1–8 Layers | 4/4 mil (0.102/0.102mm) | 0.2mm (8mil) | ≥170 W/m·K | -200℃ ~ +1900℃ | IPC-6019, MIL-PRF-32535 |

| Aluminum Substrate PCB | 1–4 Layers | 5/5 mil (0.127/0.127mm) | 0.3mm (12mil) | ≥2 W/m·K | -40℃ ~ +125℃ | IPC-2221, IEC 61249 |

| HDI PCB | 4–20 Layers | 2/2 mil (0.051/0.051mm) | 0.1mm (4mil) | 0.3 W/m·K | -40℃ ~ +125℃ | IPC-6012, IPC-6018 |

| Flexible PCB | 1–8 Layers | 3/3 mil (0.076/0.076mm) | 0.1mm (4mil) | 0.25 W/m·K | -55℃ ~ +125℃ | IPC-6013, IEC 62386 |

| High-Frequency PCB (Rogers) | 2–12 Layers | 3/3 mil (0.076/0.076mm) | 0.15mm (6mil) | 0.4 W/m·K | -40℃ ~ +150℃ | IPC-6012, Rogers Specs |

1.3 Material Selection & Compatibility

We source premium materials from trusted global suppliers to ensure performance and reliability:

- Rigid PCB: FR-4 (Tg 140℃/150℃/170℃/180℃), high-Tg FR-4 for industrial applications, halogen-free FR-4 (RoHS compliant).

- Ceramic PCB: Aluminum Nitride (AlN), Aluminum Oxide (Al₂O₃), Silicon Nitride (Si₃N₄) for extreme environments.

- Thermal Substrates: Aluminum (1060/6061 alloy), copper-core substrates for high-power devices.

- High-Frequency Materials: Rogers RO4003C, RO5880, RO3010, and Arlon AD250 for 5G, radar, and telecom equipment.

- Flexible PCB: Polyimide (PI) film (Kapton®), LCP (Liquid Crystal Polymer) for high-temperature flex applications.

1.4 Industry Applications

- Ceramic PCB: Aerospace sensors, high-power RF modules, semiconductor test equipment.

- Aluminum Substrate: High-power LEDs, automotive lighting, power inverters.

- HDI PCB: Smartphones, wearables, medical diagnostic devices.

- High-Frequency PCB: 5G base stations, satellite communication systems, radar modules.

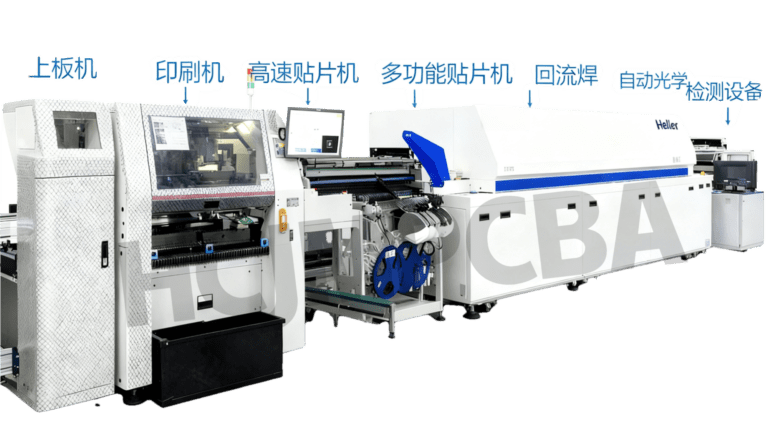

PCBA Assembly Capabilities: Precision & Reliability for Complex Designs

HCJMPCBA’s PCBA assembly capabilities combine advanced automation, strict quality control, and compliance with global standards to deliver consistent results—from micro-components (01005) to complex BGA/QFN packages.

2.1 Core Assembly Services

- SMT Assembly: Surface-mount technology for miniaturized components, high-density layouts.

- Through-Hole Assembly (THT): For power components, connectors, and devices requiring mechanical stability.

- Hybrid Assembly: Combined SMT + THT for mixed-component designs (e.g., industrial controllers).

- BGA/QFN Assembly: Fine-pitch ball grid array and quad flat no-lead packages, critical for high-performance ICs.

- Micro-Assembly: Handling ultra-small components (01005, 0201) for compact consumer electronics.

2.2 Key Technical Parameters

| Assembly Type | Component Range | Placement Accuracy | Soldering Process | Core Performance Metrics | Compliant Standards |

|---|---|---|---|---|---|

| SMT Assembly | 01005 (0.4×0.2mm) ~ 50×50mm | ±0.01mm (high-precision); ±0.025mm (high-speed) | 8-zone reflow soldering (nitrogen option) | 50,000 components/hour; first-pass yield ≥99.8% | IPC-A-610 Class II/III, IPC-J-STD-001 |

| BGA Assembly | 0.4mm pitch ~ 25×25mm | ±0.005mm | Nitrogen/vacuum reflow soldering | Void rate ≤25% (IPC-7095); X-ray inspection 100% | IPC-7095, IPC-A-610 Class III |

| Through-Hole Assembly | AWG 20~30 wires; DIP components | ±0.1mm | Wave soldering; selective soldering (for complex THT) | Flux residue <0.1mg/in²; solder joint strength ≥80N | IPC-J-STD-001, IPC-A-610 Class II |

| Micro-Assembly | 01005, 0201 components; fine-pitch QFN | ±0.008mm | High-precision reflow soldering | Component damage rate ≤0.05% | IPC-A-610 Class III, IPC-J-STD-001 |

2.3 Soldering Process Details

- Solder Material: Lead-free solder (Sn96.5Ag3.0Cu0.5) compliant with RoHS 2.0; leaded solder (Sn63Pb37) available for military/aerospace applications.

- Nitrogen Reflow: 99.99% nitrogen purity reduces oxidation, improving solder joint quality for fine-pitch components.

- Vacuum Reflow: For BGA/CSP packages, removes trapped air to minimize voids (void rate ≤25%).

- Wave Soldering: Temperature-controlled (255±5℃) with preheat zone (150–180℃) to ensure uniform soldering of THT components.

2.4 Quality Control for Assembly

- SPI (Solder Paste Inspection): Checks paste thickness (0.10–0.15mm) and uniformity, defect detection rate ≥99.5%.

- AOI (Automated Optical Inspection): 100% coverage for component placement, polarity, and solder joint defects; resolution 0.05mm.

- X-ray Inspection: For BGA/QFN w

- elding spot (1μm precision) and hidden joints; 3D X-ray option for complex packages.

- Manual Inspection: For low-volume or custom designs, performed by IPC-A-610 certified technicians.

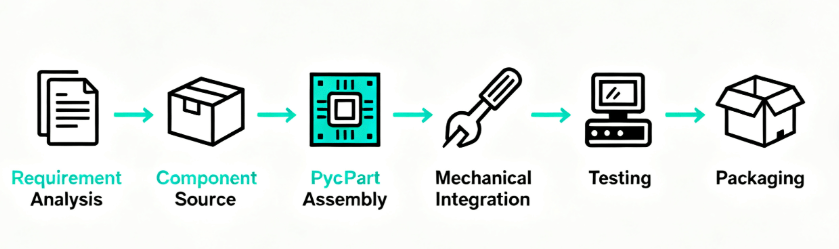

Box Build & Electronics Integration Capabilities: Turnkey Solutions

HCJMPCBA’s Box Build EMS capabilities integrate PCB assembly, component sourcing, mechanical integration, and testing into a single, seamless solution—delivering fully functional electronic devices ready for deployment.

3.1 Core Integration Services

Our end-to-end Box Build services cover:

- PCB assembly (SMT/THT/BGA)

- Component sourcing (electronics, structural parts, cables)

- Cable harnessing (crimping, welding, labeling for AWG 20~30)

- Mechanical integration (enclosure assembly, heat sink mounting, hardware installation)

- Waterproof/dustproof treatment (IP65/IP67 rating)

- Functional & environmental testing

- Custom packaging (anti-static, industrial, medical-grade)

3.2 Key Performance Parameters

- Integration Precision: Structural component tolerance ±0.1mm; cable crimping force ≥80N (IPC-A-620 compliant).

- Thermal Management: Aluminum heat sinks (thermal conductivity ≥200W/m·K), heat pipes (thermal resistance ≤0.2℃/W), and thermal interface materials (TIM) for high-power devices.

- Protection Ratings: IP65 (industrial environments) and IP67 (automotive/outdoor applications); custom ratings available.

- Cable Harnessing: Wire stripping length 5–8mm; insulation resistance ≥100MΩ; voltage rating up to 600V.

3.3 Box Build Integration Process

| Process Step | Key Activities | Quality Checkpoints | Cycle Time (Per Unit) |

|---|---|---|---|

| 1. Requirement Analysis | Define integration scope, standards, and testing needs | Signed requirement document | 1–2 Business Days |

| 2. Component Sourcing | Source PCBs, components, enclosures, and cables | IQC inspection (qualified rate≥99.9%) | 3–7 Business Days |

| 3. PCB Assembly | SMT/THT/BGA assembly + AOI/X-ray inspection | First-pass yield ≥99.8% | 1–3 Business Days |

| 4. Mechanical Integration | Enclosure assembly, heat sink mounting, cable routing | Fit tolerance ±0.1mm; heat sink fit rate ≥95% | 0.5–2 Hours |

| 5. Testing | Functional + environmental testing (as required) | Test pass rate ≥99.5% | 0.2–1 Hour |

| 6. Packaging & Delivery | Custom packaging + labeling + shipping | Packaging integrity check | 1–2 Business Days |

3.4 Typical Applications

- Industrial control systems (PLCs, HMIs, sensors)

- Medical devices (diagnostic equipment, patient monitors)

- Automotive electronics (onboard controllers, infotainment systems)

- Consumer electronics (smart home devices, wearable tech)

Testing & Quality Assurance Capabilities: Compliance & Reliability

HCJMPCBA’s testing and quality assurance capabilities ensure every product meets technical specifications, industry standards, and customer expectations—with a defect rate ≤500ppm.

4.1 Comprehensive Testing Services

Electrical Testing

- ICT (In-Circuit Testing): 100% coverage for component continuity, short circuits, and parametric values; test time ≤30 seconds/unit.

- FCT (Functional Testing): Customized test fixtures for verifying device performance (e.g., voltage output, signal transmission, user interface); test coverage 100%.

- Boundary Scan Testing: For complex PCBs with JTAG-compliant components (e.g., BGA, FPGA); detects interconnections and component defects.

Reliability Testing

- Temperature-Humidity Cycling: -40℃ ~ +125℃, 500 cycles (1 cycle = 24 hours); no performance degradation allowed.

- Vibration Testing: 10–2000Hz frequency, 10g acceleration (IEC 60068-2-6); no mechanical damage or functional failure.

- Salt Spray Testing: 5% NaCl solution, 500 hours (ASTM B117); no corrosion on metal components.

- ESD Protection Testing: ±100V contact discharge, ±200V air discharge (IEC 61000-4-2); no permanent damage.

Specialized Testing

- BGA X-ray Inspection: 3D imaging for void detection (void rate ≤25%) and solder joint integrity.

- PCB Warpage Testing: Warpage ≤0.75% (IPC-6012); measured via laser scanning.

- Solder Joint Strength Testing: Pull force ≥80N for THT components, ≥30N for SMT components (IPC-J-STD-001).

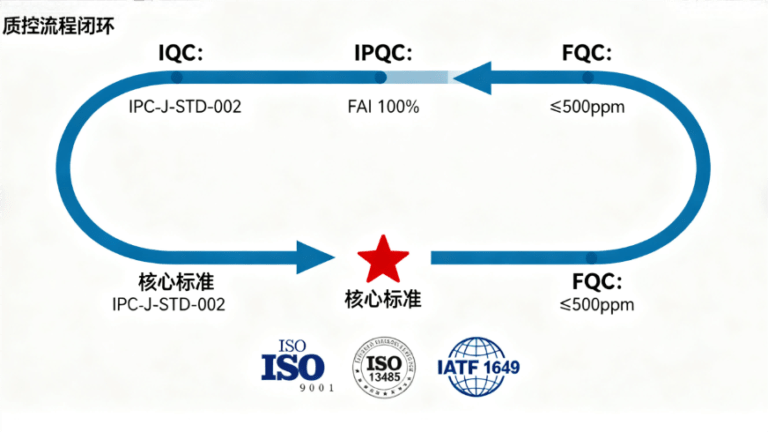

4.2 Three-Stage Quality Control System

- IQC (Incoming Quality Control): Inspect PCBs, components, and structural parts before production.

- PCB: Warpage ≤0.75%, surface cleanliness ≥99.5%, trace width tolerance ±10%.

- Components: Authenticity verification, solderability ≥95% (IPC-J-STD-002), no visual defects.

- IPQC (In-Process Quality Control): Monitor production stages with scheduled inspections.

- First Article Inspection (FAI): 100% check of the first unit for each order.– Inspection Frequency: Every 2 hours for mass production; 100% inspection for critical processes (BGA assembly, cable crimping).

- First Article Inspection (FAI): 100% check of the first unit for each order.

- FQC (Final Quality Control): Comprehensive inspection of finished products.

- Functional testing + visual inspection + packaging check.

- Defect rate ≤500ppm; non-conforming products are reworked or rejected.

4.3 Compliance Certifications

We hold global certifications to meet industry-specific requirements:

- ISO 9001: General quality management system.

- ISO 13485: Medical device manufacturing (compliant with FDA 21 CFR Part 820).

- IATF 16949: Automotive electronics manufacturing (compliant with AEC-Q100/Q200).

- RoHS 2.0: Restriction of hazardous substances (Pb, Cd, Hg, etc.).

- REACH: Compliance with EU chemical regulations.

Industry-Specific Capabilities: Tailored Solutions for Key Sectors

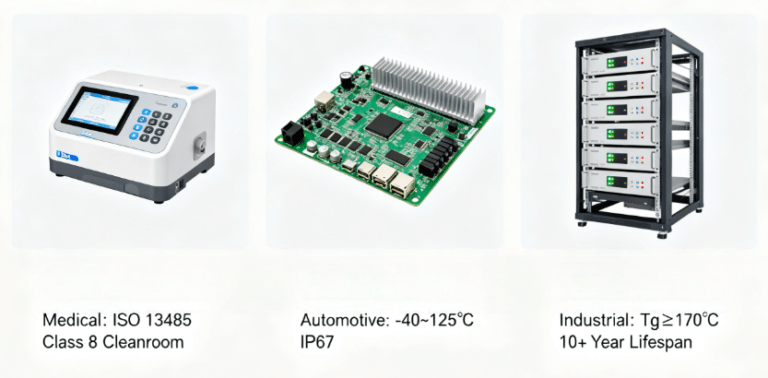

HCJMPCBA’s capabilities are optimized for the unique requirements of medical, automotive, industrial, and consumer electronics—combining technical precision, compliance, and industry expertise.

5.1 Medical Device PCB/PCBA Capabilities

- Core Compliance: ISO 13485, FDA 21 CFR Part 820, IPC-A-610 Class III.

- Key Features:

- Biocompatible materials (ISO 10993 certified) for patient-contact devices.

- Cleanroom manufacturing (Class 8) to minimize contamination.

- Traceability: Lot numbers for all components, full production records (retained for 10 years).

- Low-noise designs for sensitive diagnostic equipment.

- Applications: Diagnostic scanners, patient monitors, infusion pumps, wearable health trackers.

5.2 Automotive Electronics Capabilities

- Core Compliance: IATF 16949, AEC-Q100/Q200, ISO 16750.

- Key Features:

- Wide temperature range (-40℃ ~ +125℃) for under-hood and cabin applications.

- Vibration resistance (10–2000Hz, 5g) and IP67 waterproof rating.

- High-reliability components (MTBF ≥100,000 hours).

- Lead-free soldering (Sn96.5Ag3.0Cu0.5) compliant with ELV regulations.

- Applications: Onboard controllers, LED headlights, EV power modules, infotainment systems.

5.3 Industrial Control Capabilities

- Core Compliance: IEC 61010, IPC-A-610 Class II, ISO 9001.

- Key Features:

- High-Tg materials (Tg ≥170℃) for long-term operation in harsh environments.

- Conformal Coating (IPC-CC-830) for dust, moisture, and chemical resistance.

- EMI shielding to prevent interference with other industrial equipment.

- Extended lifespan (10+ years) with robust component selection.

- Applications: PLCs, industrial sensors, motor drives, factory automation systems.

5.4 Consumer Electronics Capabilities

- Core Compliance: RoHS 2.0, CE, FCC.

- Key Features:

- HDI and miniaturized designs (board thickness 0.2mm) for compact devices.

- Cost optimization via bulk sourcing and efficient manufacturing.

- Fast turnaround for time-sensitive product launches.

- Customizable packaging and branding.

- Applications: Smartphones, tablets, wearables, smart home devices, routers.

Production & Delivery Capabilities: Scalability & Speed

HCJMPCBA’s production capabilities adapt to your volume needs—from rapid prototypes to high-volume production—with reliable lead times and global delivery.

6.1 Production Volume Adaptability

| Production Type</ | Volume Range</ | Lead Time</ | Key Advantages</ |

|---|---|---|---|

| Prototype | 1–10 Units | 24–48 Hours(expedited); 3–5 Days (standard) | Fast turnaround for design validation |

| Low-Volume Production | 10–500 Units | 7–12 Days | Flexible customization, no minimum order |

| Medium-Volume Production | 500–10,000 Units | 12–18 Days | Balanced cost and speed |

| High-Volume Production | 10,000+ Units | 15–25 Days | Bulk pricing, dedicated production lines |

6.2 Expedited Service

- Prototype expedited: 24–48 hour delivery for PCB/PCBA prototypes (requires error-free files and in-stock components).

- Low-Volume expedited: 5–7 days for 10–500 units (priority production line allocation).

- Rush Fees: 30–50% premium on standard pricing (varies by volume and complexity).

6.3 Supply Chain & Logistics

- Supplier Network: 400+ qualified global suppliers for components, materials, and structural parts; procurement lead time stability ≥98%.

- Component Management: Obsolete component replacement (fast validation of drop-in alternatives) and long-lead-time component pre-stocking.

- Global Delivery: Partner with DHL, FedEx, and ocean freight carriers; door-to-door delivery to 100+ countries.

- Customs Compliance: Support for export documentation (commercial invoice, packing list, certificate of origin, compliance certificates).

Value-Added Capabilities: Beyond Manufacturing

HCJMPCBA offers value-added services to streamline your workflow, reduce costs, and ensure project success—from design to delivery.

7.1 Technical Support Services

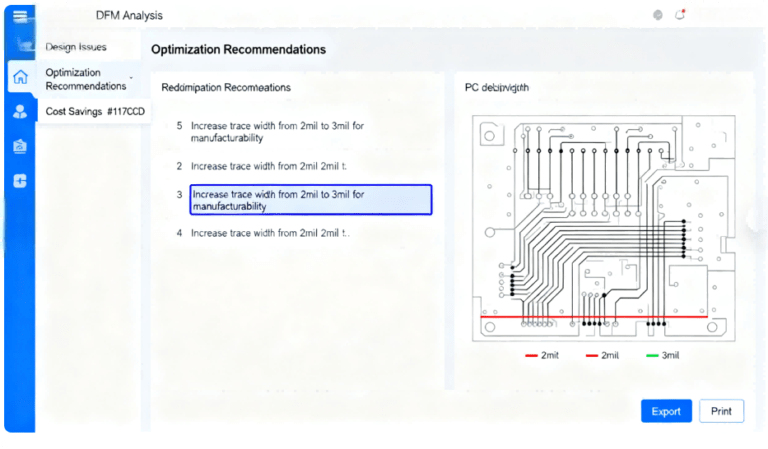

- Free DFM (Design for Manufacturability) Analysis: Review your PCB/PCBA designs to optimize for manufacturing, reduce defects, and lower costs.

- Key checks: Component footprint compatibility, trace width/spacing, via size, solder mask coverage.

- Delivery: Detailed DFM report within 24–48 hours of file submission.

- Design Optimization: Recommendations for thermal management, EMI reduction, and assembly efficiency.

- Technical Consultation: 24-hour support from IPC-certified engineers for design, material, and process questions.

7.2 Supply Chain Services

- Component Sourcing: Global procurement of electronic components, structural parts, and cables—with cost savings of 15–25% via bulk purchasing.

- Obsolete Component Management: Proactive alerts for end-of-life (EOL) components; fast identification and validation of drop-in alternatives.

- BOM Optimization: Reduce costs by replacing high-cost components with compatible, lower-cost alternatives (without compromising performance).

- Component Storage: Secure storage of long-lead-time or high-value components (temperature-controlled, anti-static facilities).

7.3 Project Management Services

- End-to-End Project Tracking: Real-time visibility into production progress, testing results, and shipping status via our online portal.

- Dedicated Project Managers: Single point of contact for all project-related communications (quotes, updates, issue resolution).

- Documentation Delivery: Comprehensive reports including test data, inspection results, compliance certificates, and traceability records.

- After-Sales Support: 90-day warranty for all products; free rework for manufacturing defects; technical support for post-delivery issues.

Capabilities Summary: Why Choose HCJMPCBA?

HCJMPCBA’s comprehensive capabilities deliver unmatched value for OEM engineers, procurement teams, and cross-industry clients—combining precision, compliance, scalability, and speed. Our key strengths include:

- Full Industry Chain Coverage: From PCB manufacturing and PCBA assembly to Box Build integration and testing—one partner for all your electronics needs.

- High-Precision Processes: ±0.01mm SMT placement, BGA void rate ≤25%, structural integration tolerance ±0.1mm—meeting the most demanding technical requirements.

- Global Compliance: ISO 9001/13485/IATF 16949 certifications, RoHS 2.0 compliance, and industry-specific standards (medical/automotive) to mitigate risk.

- Cross-Industry Expertise: Tailored solutions for medical, automotive, industrial, and consumer electronics—with deep knowledge of sector-specific needs.

- Scalable Production: Adaptable to prototypes (24–48 hour delivery) and high-volume production (10k+ units) with reliable lead times.

- Value-Added Services: Free DFM analysis, BOM optimization, and 24-hour technical support—reducing costs and streamlining workflows.