HCJMPCBA SMT Assembly Capability

High-Precision Surface Mount Technology Solutions

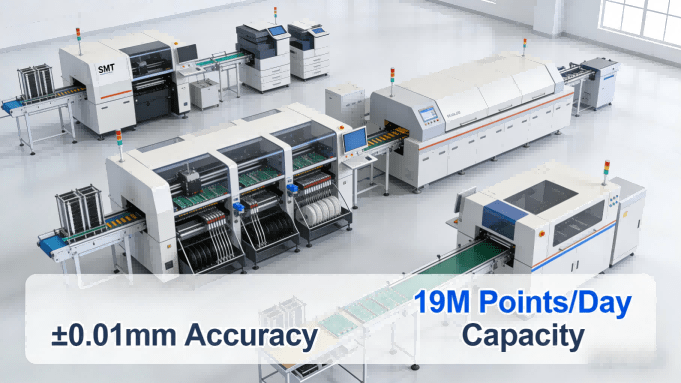

1. SMT Assembly Overview: HCJMPCBA’s Core Strengths

For OEM engineers, procurement decision-makers, and cross-industry clients, surface mount technology (SMT) is the backbone of modern electronic manufacturing—and HCJMPCBA’s smt assembly capability delivers the precision, scalability, and compliance needed to turn complex designs into reliable products.

1.1 What is Surface Mount Technology (SMT)?

Surface mount technology (SMT)—often referred to as surface-mount technology—is a manufacturing process that mounts electronic components (called smt components) directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology (which requires drilling holes for component leads), SMT enables higher component density, faster production, and lower costs for most electronic devices.

Key advantages of SMT over through-hole assembly:

- Higher Density: Supports micro-components (e.g., 01005 resistors) for compact designs (critical for smt prototype board and consumer electronics).

- Faster Production: Fully automated equipment reduces labor time and improves consistency.

- Lower Cost: Smaller component sizes and automated processes cut material and labor expenses.

- Better Reliability: Solder joints have stronger mechanical bonds and better electrical performance for high-vibration applications (e.g., automotive electronics).

Keywords: what is a smt, surface-mount technology, what are smt components

1.2 HCJMPCBA SMT Assembly Capability Highlights

As a leading smt assembler for PCB/PCBA solutions, HCJMPCBA’s core capabilities are engineered to meet the most demanding technical and production needs:

- Full Component Compatibility: Mounts components from 01005 micro-resistors to 0.3mm-pitch BGA (ball grid array) packages—covering passive, active, and special components.

- Ultra-High Precision: ±0.01mm placement accuracy for chips; ±0.005mm for BGA/QFN components (critical for high-precision medical/automotive devices).

- Fully Automated Workflow: End-to-end automation (solder paste printing → component mounting → reflow soldering → inspection) reduces human error and boosts throughput.

- Multi-Industry Adaptability: Compliant with standards for medical, automotive, industrial, and consumer electronics—delivering tailored solutions for every sector.

Keywords: smt assembly capability, surface mount assembly, smt pcb assembly

1.3 Why Choose HCJMPCBA for SMT Assembly?

For OEM engineers and procurement teams, HCJMPCBA stands out through data-driven performance and customer-centric flexibility:

- Quality You Can Measure: ≤300ppm defect rate (IPC-A-610 Class II/III); ≤150ppm for medical/automotive applications.

- Scalable Production: Supports 1-unit smt prototype board (24–48h delivery) to 19-million-point daily mass production—no minimum order quantity (MOQ).

- Global Compliance: Certified to ISO 9001 (general manufacturing), IATF 16949 (automotive), ISO 13485 (medical), and RoHS 2.0—mitigating regulatory risk for cross-border projects.

- Transparent Project Management: Real-time tracking of production, inspection, and delivery via our online portal—keeping you informed at every step.

2. Core SMT Assembly Capabilities

HCJMPCBA’s smt assembly capability is built on advanced equipment, strict process control, and deep technical expertise—covering every stage of surface mount production.

2.1 Component Compatibility Range

We support a full spectrum of smt components (passive, active, and special) to accommodate designs from simple consumer devices to complex industrial controllers:

Passive Components

- Resistors/Capacitors: 01005 (0.4×0.2mm) → 2512 (6.3×3.2mm); including high-precision (±0.1%) and high-voltage (≥1kV) variants.

- Inductors: 0201 → 1210; power inductors up to 5A current rating.

Active Components

- IC Packages: QFP (0.4mm pitch), QFN (0.3mm pitch), BGA (0.3mm pitch), uBGA, PoP (Package-on-Package), SOIC, PLCC, and LGA.

- Microcontrollers (MCUs): 8-pin to 200-pin packages; including low-power and high-performance variants.

Special Components

- High-Power SMD: MOSFETs, IGBTs, and power modules (up to 100A current rating).

- Thermal Sensors: NTC/PTC thermistors; temperature range -55℃ to +150℃.

- Odd-Form Components: Connectors, switches, and LEDs (up to 32mm in length).

Keywords: what are smt components, pcb smd, surface mount pcb assembly

2.2 Advanced SMT Equipment Portfolio

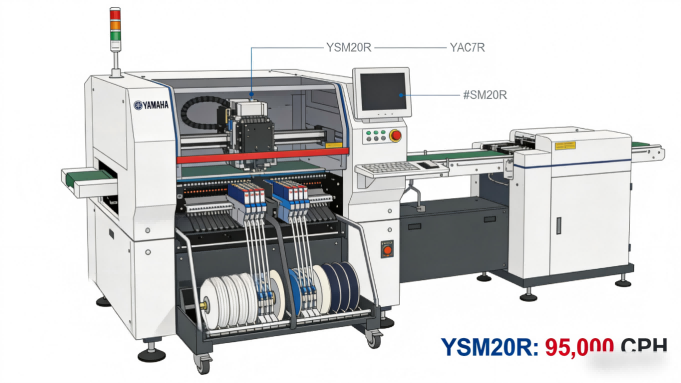

Our surface mount technology equipment is selected for precision, speed, and reliability—ensuring consistent performance across prototype and mass production runs:

| Equipment Type | Model | Key Specifications | Application Scenario |

|---|---|---|---|

| Solder Paste Printer | GKG GLS | Printing accuracy: ±0.018mm; PCB size: 50×50 ~ 610×510mm; paste thickness control: 0.10~0.15mm | High-precision SMT for HDI PCBs and micro-components |

| Surface Mount Machine | Yamaha YSM20R | Placement speed: 95,000 CPH (components per hour); accuracy: ±0.01mm; component range: 01005 ~ 32mm | High-volume, high-precision production |

| Yamaha YS24 | Placement speed: 72,000 CPH; accuracy: ±0.02mm; component range: 0201 ~ 32mm | Small-batch and prototype production | |

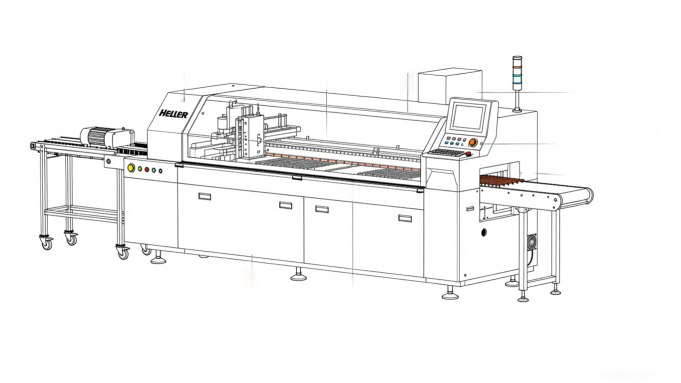

| Reflow Oven | Heller 1809EXL | 8 temperature zones; temperature range: 20~260℃; nitrogen protection (99.99% purity optional) | Lead-free soldering; BGA/QFN packages |

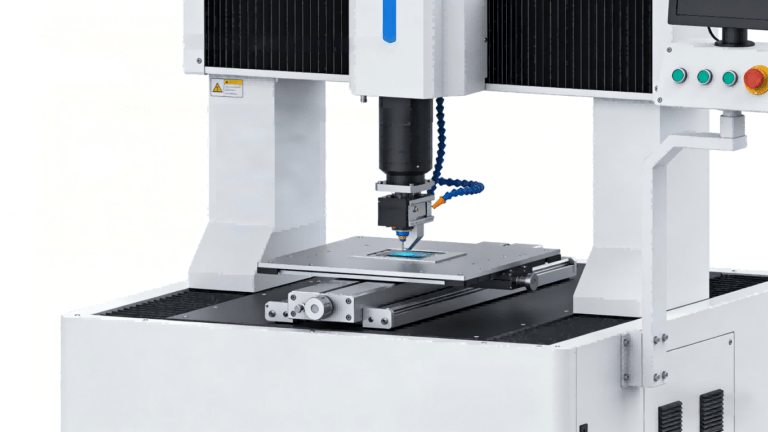

| 3D SPI (Solder Paste Inspection) | Koh Young KY8030 | Resolution: 1μm; inspection speed: <200ms/FOV; detects paste volume/height/offset | Pre-mounting quality control |

| Online AOI (Automated Optical Inspection) | ALD7727D | Resolution: 5μm; inspection speed: <230ms/FOV; 100% coverage for component placement/polarity | Post-mounting defect detection |

| X-Ray Inspection | ViTrox VX1800 | Magnification: 6000×; resolution: 1μm; detects BGA voids, short circuits, and hidden defects | BGA/QFN package inspection |

Keywords: surface mount technology equipment, smt assembler, smt mounting

2.3 SMT Assembly Process Flow

HCJMPCBA’s surface mount technology process follows a standardized, parameter-controlled workflow to ensure consistency and quality—with built-in quality checkpoints at every stage:

- Pre-Production Preparation & IQC

- Source PCBs, smt components, and custom stencils (steel or nickel-plated).

- IQC (Incoming Quality Control): Verify component authenticity; test PCB flatness (warpage ≤0.75%); check solder paste shelf life (≤6 months).

- Key Parameter: Component solderability ≥95% (IPC-J-STD-002).

- Solder Paste Printing

- Use GKG GLS printer to apply solder paste to PCB pads via custom stencil.

- 3D SPI Inspection: Confirm paste thickness (0.10~0.15mm) and volume (deviation ≤±10%).

- Component Placement

- Load components into Yamaha YSM20R/YS24 mount machines (automated feeder system).

- Mount components per Gerber/BOM data; perform First Article Inspection (FAI 100%) for the first unit.

- Key Parameter: Component placement offset ≤±0.01mm (chips) / ±0.005mm (BGA).

- Reflow Soldering

- Convey PCBA through Heller 1809EXL oven with controlled temperature curve:

- Preheat: 140~160℃ (60–90 seconds) → Soak: 160~180℃ (60–90 seconds) → Reflow: 210~230℃ (30–60 seconds) → Cool: ≤3℃/second.

- Nitrogen protection (optional) reduces oxidation for fine-pitch components.

- Convey PCBA through Heller 1809EXL oven with controlled temperature curve:

- Post-Soldering Inspection & Rework

- Online AOI: 100% inspection for component polarity, placement, and solder joint defects.

- X-Ray Inspection: For BGA/QFN packages (detect voids ≤25% per IPC-7095).

- Rework (if needed): Repair defects with precision tools (e.g., BGA rework station).

- Final Quality Control (FQC) & Packaging

- Functional testing (if required): Verify device performance per customer specs.

- Clean PCBA (residue <0.1mg/in²); package in anti-static materials.

Keywords: surface mount technology process, smt assembly process, pcb smt assembly

3. Quantified SMT Assembly Parameters

For OEM engineers and procurement decision-makers, data-driven performance is non-negotiable. HCJMPCBA’s smt assembly capability is defined by the following quantified specifications:

| Parameter Category | Technical Specifications | Applicable Scenarios |

|---|---|---|

| Component Mounting Range | 01005 (0.4×0.2mm) ~ 45×45mm; BGA pitch ≥0.3mm | Consumer electronics, industrial control, medical devices |

| Mounting Accuracy | Chip: ±0.01mm; BGA/QFN: ±0.005mm | High-precision PCBA (automotive electronics, aerospace) |

| Production Capacity | Prototype: 1~100 units/24-48h; Mass production: 19 million points/day | Rapid prototyping, high-volume orders |

| PCB Compatibility | Size: 50×50mm ~ 810×490mm; Thickness: 0.2~6.0mm | Rigid PCB, flex PCB, rigid-flex PCB, metal core PCB |

| Defect Rate | ≤300ppm (IPC-A-610 Class II/III); Medical/Automotive: ≤150ppm | All industries (critical applications: medical/automotive) |

| Solder Joint Quality | BGA void rate ≤25% (IPC-7095); Solder joint pull force ≥30N (SMT) / ≥80N (THT) | High-reliability devices (automotive, industrial) |

4. Quality Control & Compliance

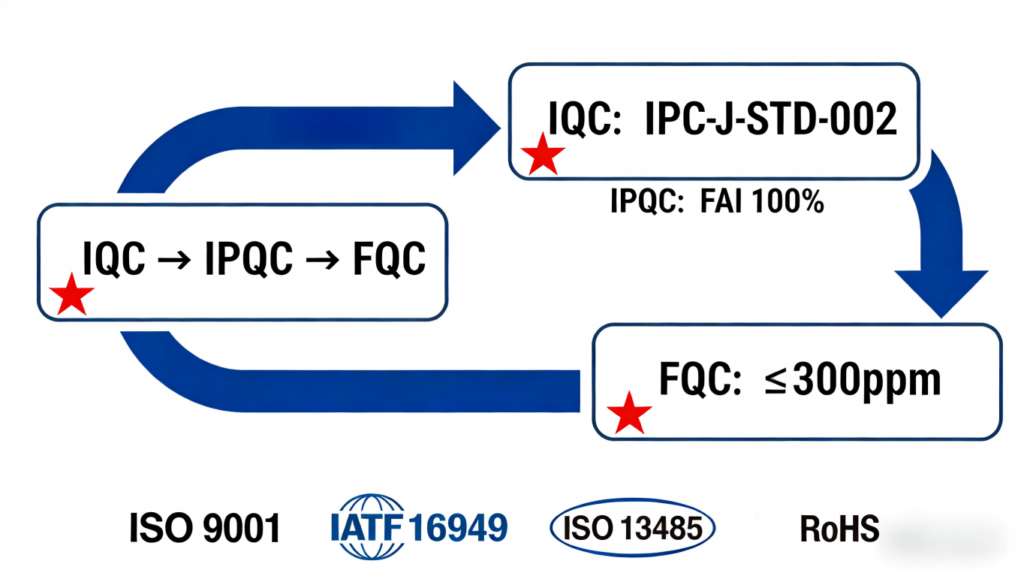

HCJMPCBA’s smt assembly quality control system follows a three-stage inspection process—backed by global certifications—to ensure every PCBA meets your technical and regulatory requirements.

4.1 Three-Stage Quality Inspection

IQC (Incoming Quality Control):

- PCB Inspection: Warpage ≤0.75% (IPC-6012); surface cleanliness ≥99.5%.

- Component Inspection: Authenticity verification (anti-counterfeit labels); solderability ≥95% (IPC-J-STD-002); no visual defects.

- Solder Paste Inspection: Shelf life ≤6 months; viscosity 100–200 Pa·s (at 25℃).

IPQC (In-Process Quality Control):

- Scheduled Inspections: Every 2 hours for mass production; 100% inspection for prototype runs.

- First Article Inspection (FAI): Verify component placement, solder paste thickness, and polarity for the first unit of every order.

- Real-Time Monitoring: Reflow oven temperature curve (logged every 10 seconds); placement accuracy (sampled every 50 units).

FQC (Final Quality Control):

- AOI Inspection: 100% coverage for component placement, polarity, and solder joint defects.

- X-Ray Inspection: Mandatory for BGA/QFN packages (void rate ≤25%).

- Functional Testing: Custom test fixtures for device performance (e.g., voltage output, signal transmission).

- Packaging Inspection: Anti-static materials; traceability labels (lot number, production date, inspector ID).

4.2 Global Compliance Certifications

HCJMPCBA’s smt assembly capability is certified to meet the strictest industry standards:

- ISO 9001: General quality management system (consistent production and customer satisfaction).

- IATF 16949: Automotive electronics manufacturing (compliant with AEC-Q100/Q200).

- ISO 13485: Medical device manufacturing (compliant with FDA 21 CFR Part 820).

- RoHS 2.0: Restriction of hazardous substances (Pb, Cd, Hg, etc.).

5. Industry-Specific SMT Assembly Solutions

HCJMPCBA’s smt assembly capability is tailored to the unique requirements of medical, automotive, industrial, and consumer electronics—combining technical precision with sector-specific compliance.

5.1 Medical Device SMT Assembly

Medical devices demand ultra-high reliability and regulatory compliance—our solutions meet ISO 13485 and clinical safety standards:

- Key Capabilities:

- Class 8 Cleanroom Production: Minimize contamination (particle count ≤352,000 particles/m³ at 0.5μm).

- Low-Noise Design: Component placement for minimal electromagnetic interference (EMI) in diagnostic equipment.

- Biocompatible Materials: Solder and components compliant with ISO 10993 (no toxic leaching).

- Full Traceability: Batch records retained for 10 years (required for FDA audits).

- Applications: Diagnostic scanners, patient monitors, infusion pumps, wearable health trackers.

Keywords: medical smt assembly, smt prototype board

5.2 Automotive Electronics SMT Assembly

Automotive devices operate in harsh environments (temperature, vibration)—our solutions meet IATF 16949 and AEC-Q100:

- Key Capabilities:

- Wide Temperature Range: Components and PCBs rated for -40℃ to +125℃.

- Vibration Resistance: Solder joints tested to 10~2000Hz (10g acceleration; IEC 60068-2-6).

- IP67 Protection: Sealed PCBA for under-hood and outdoor applications.

- Lead-Free Soldering: Sn96.5Ag3.0Cu0.5 (compliant with ELV regulations).

- Applications: Onboard controllers, LED headlights, EV power modules, infotainment systems.

5.3 Industrial Control SMT Assembly

Industrial controllers require long-term reliability and resistance to dust/moisture—our solutions meet IEC 61010:

- Key Capabilities:

- High-Tg PCBs: Tg ≥170℃ (resistant to thermal stress in high-power devices).

- Conformal Coating: IPC-CC-830-compliant coating for dust, moisture, and chemical resistance.

- Extended Lifespan: MTBF (Mean Time Between Failures) ≥100,000 hours.

- EMI Shielding: Copper foil or conductive coating to prevent interference.

- Applications: PLCs, industrial sensors, motor drives, factory automation systems.

5.4 Consumer Electronics SMT Assembly

Consumer devices demand miniaturization and cost efficiency—our solutions balance precision and affordability:

- Key Capabilities:

- Micro-Component Mounting: 01005 components for compact designs (e.g., smartwatches).

- HDI PCB Compatibility: 2~20 layer HDI with 2/2mil line width/spacing.

- Rapid Turnaround: 24~48h for smt prototype board; 5~7 days for small-batch production.

- Cost Optimization: Bulk component sourcing (15~25% cost reduction).

- Applications: Smartphones, tablets, wearables, smart home devices, routers.

6. SMT Assembly Selection Guide

Choosing the right smt assembly capability depends on your project’s volume, complexity, and industry requirements. HCJMPCBA’s technical team helps you select the optimal solution:

6.1 How to Choose SMT Assembly for Your Project?

| Project Type | Volume Range | Recommended Equipment | Lead Time | Key Considerations |

|---|---|---|---|---|

| Prototype | 1~10 units | Yamaha YS24 + Manual Inspection | 24~48h | Fast turnaround; design validation |

| Small-Batch Production | 10~500 units | Yamaha YS24 + Online AOI | 5~7 days | Flexibility; minimal setup cost |

| Medium-Batch Production | 500~10,000 units | Yamaha YSM20R + 3D SPI/AOI | 12~18 days | Balance of speed and cost |

| High-Volume Production | 10,000+ units | Dual Yamaha YSM20R + Full Automation | 15~25 days | Maximum throughput; bulk cost savings |

6.2 Common SMT Assembly Challenges & Solutions

- BGA Voids: Cause: Trapped air during reflow. Solution: Vacuum reflow oven (reduces voids to ≤25%).

- Solder Paste Printing Unevenness: Cause: Stencil wear or incorrect pressure. Solution: 3D SPI inspection + stencil cleaning every 50 PCBs.

- Component Misalignment: Cause: Feeder vibration or incorrect placement parameters. Solution: Real-time placement accuracy monitoring + feeder calibration.

- Tombstoning (Component Standing): Cause: Uneven solder paste melting. Solution: Optimized reflow temperature curve + balanced pad design.

6.3 Component Obsolescence Management

Obsolete smt components can delay production—HCJMPCBA offers proactive solutions:

- Early Alerts: Monitor component lifecycle (via Octopart/PartMiner) and notify you 6~12 months before EOL (End of Life).

- Drop-In Replacements: Source compatible components (same footprint, electrical specs) and validate performance.

- Pre-Stocking: Store long-lead-time components (e.g., custom ICs) to avoid production gaps.

7. Value-Added Services

Beyond smt assembly capability, HCJMPCBA offers value-added services to streamline your workflow and reduce costs:

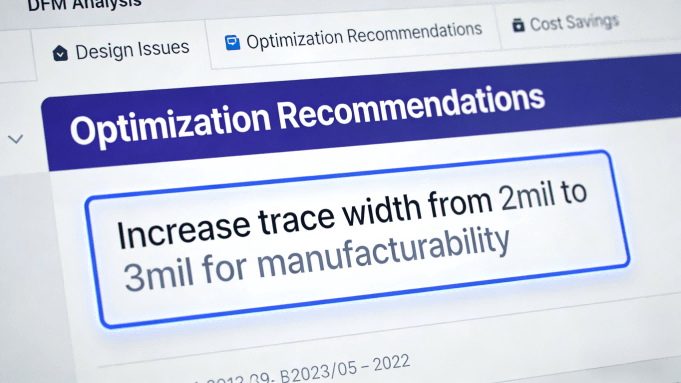

7.1 Free DFM Analysis for SMT Assembly

Our IPC-certified engineers provide Design for Manufacturability (DFM) analysis—free for all projects:

- Optimize component placement (reduce cross-talk and thermal stress).

- Recommend pad sizes (match component leads for better solder joints).

- Adjust stencil design (improve solder paste transfer efficiency).

- Identify potential production defects (e.g., tombstoning, short circuits).

- Delivery: Detailed DFM report within 24~48h of file submission.

7.2 Prototype & Small-Batch Rapid Service

For time-sensitive projects, our smt prototype assembly service delivers fast results:

- Prototype: 24~48h delivery (requires error-free Gerber/BOM files and in-stock components).

- Small-Batch: 5~7 days for 10~500 units (priority production line allocation).

- Rush Fees: 30~50% premium (varies by volume and complexity).

7.3 Full Documentation Support

We provide comprehensive documentation for audit and traceability:

- Production Reports: Placement accuracy, reflow temperature curves, inspection results.

- Compliance Certificates: ISO 9001/IATF 16949/ISO 13485/RoHS 2.0.

- Traceability Records: Component lot numbers, production dates, inspector IDs.

- Test Data: AOI/X-Ray reports, functional test results.

8. Get a Custom SMT Assembly Quote

HCJMPCBA’s smt assembly capability is tailored to your project’s unique needs—whether you need a smt prototype board or high-volume production. To request a quote:

- Submit Your Files: Upload PCB Gerber files, BOM (Bill of Materials), and component specifications via our online portal.

- Specify Requirements: Indicate volume, industry, compliance standards, and lead time needs.

- Get a Quote: Our technical team will provide a detailed quote (including cost, lead time, and quality guarantees) within 24 hours.

Why HCJMPCBA Stands Out for SMT Assembly

HCJMPCBA’s smt assembly capability combines precision, scalability, and compliance to deliver solutions that meet the needs of OEM engineers, procurement decision-makers, and cross-industry clients:

- Full Component Compatibility: 01005 to BGA (0.3mm pitch) — no design limitations.

- Quantified Performance: ±0.01mm accuracy, ≤300ppm defect rate, 19M points/day capacity.

- Global Compliance: ISO 9001/IATF 16949/ISO 13485 — mitigate regulatory risk.

- Customer-Centric Services: Free DFM analysis, rapid prototypes, full documentation.