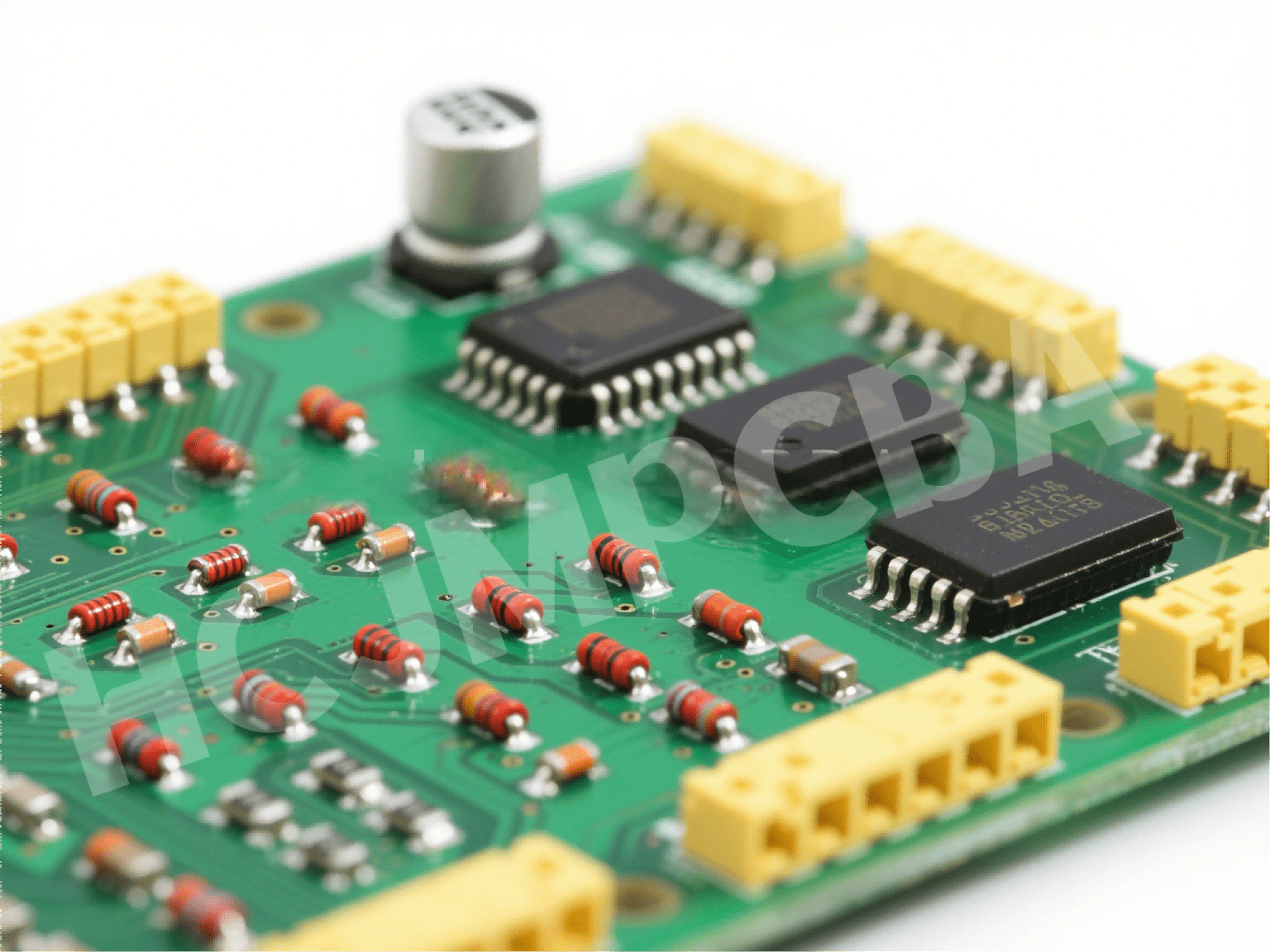

PCBA Assembly: 7 Essential Components You Need to Know

Discover what PCBA assembly is, why it matters in modern electronics, and explore the 7 most common

ISO 13485-Certified LED PCBA Manufacturing: High-Reliability Solutions for Medical, Automotive, and 5G Applications

Table of Contents

ToggleDiscover what PCBA assembly is, why it matters in modern electronics, and explore the 7 most common

This article provides an in-depth exploration of PCBA technology, its evolution, key processes, chal

Discover how HCJMPCBA leverages the advanced Samsung SM471 machine to optimize the PCB manufacturing