Full Turnkey – High Quality – Quick Turn

PCB Assembly Services

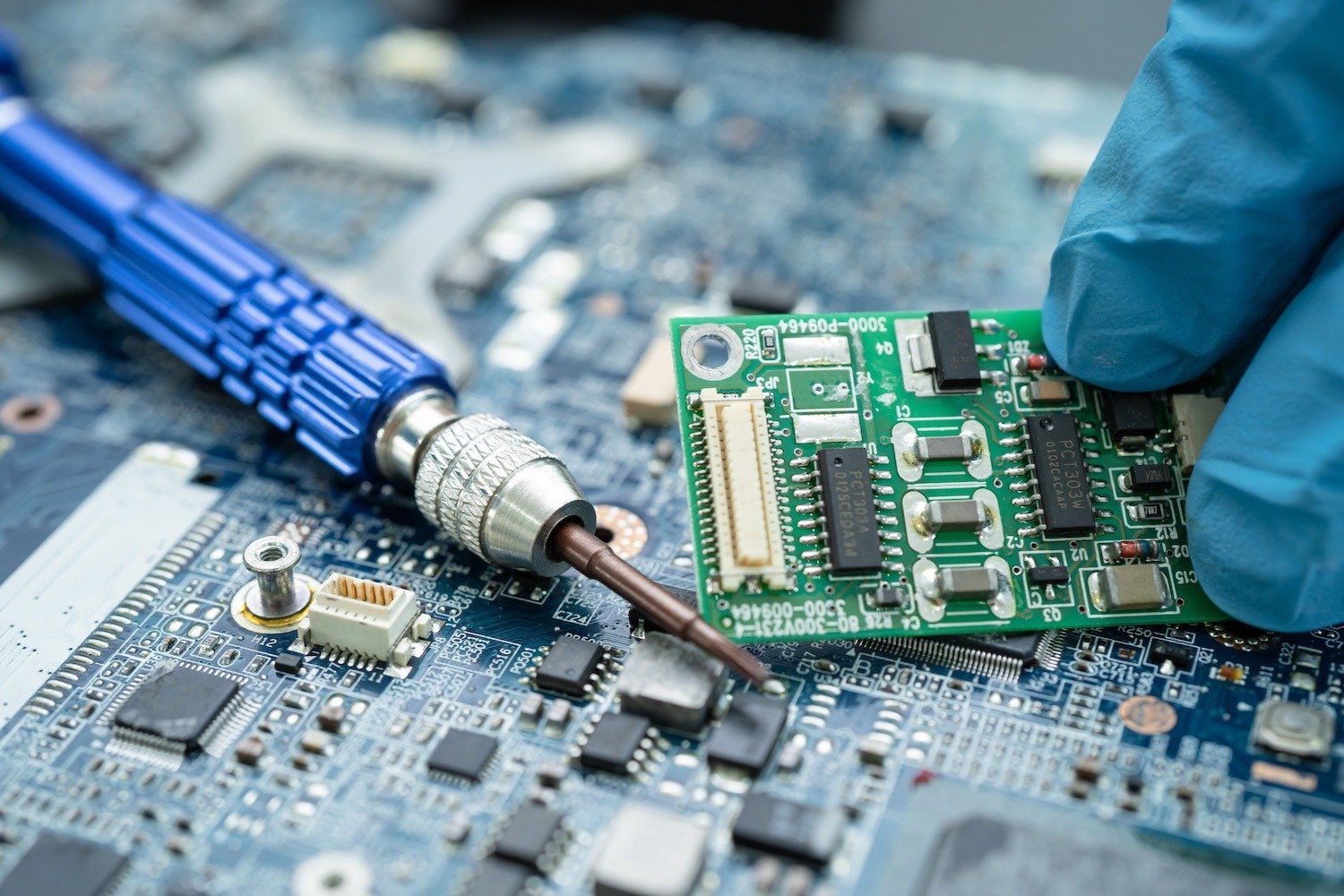

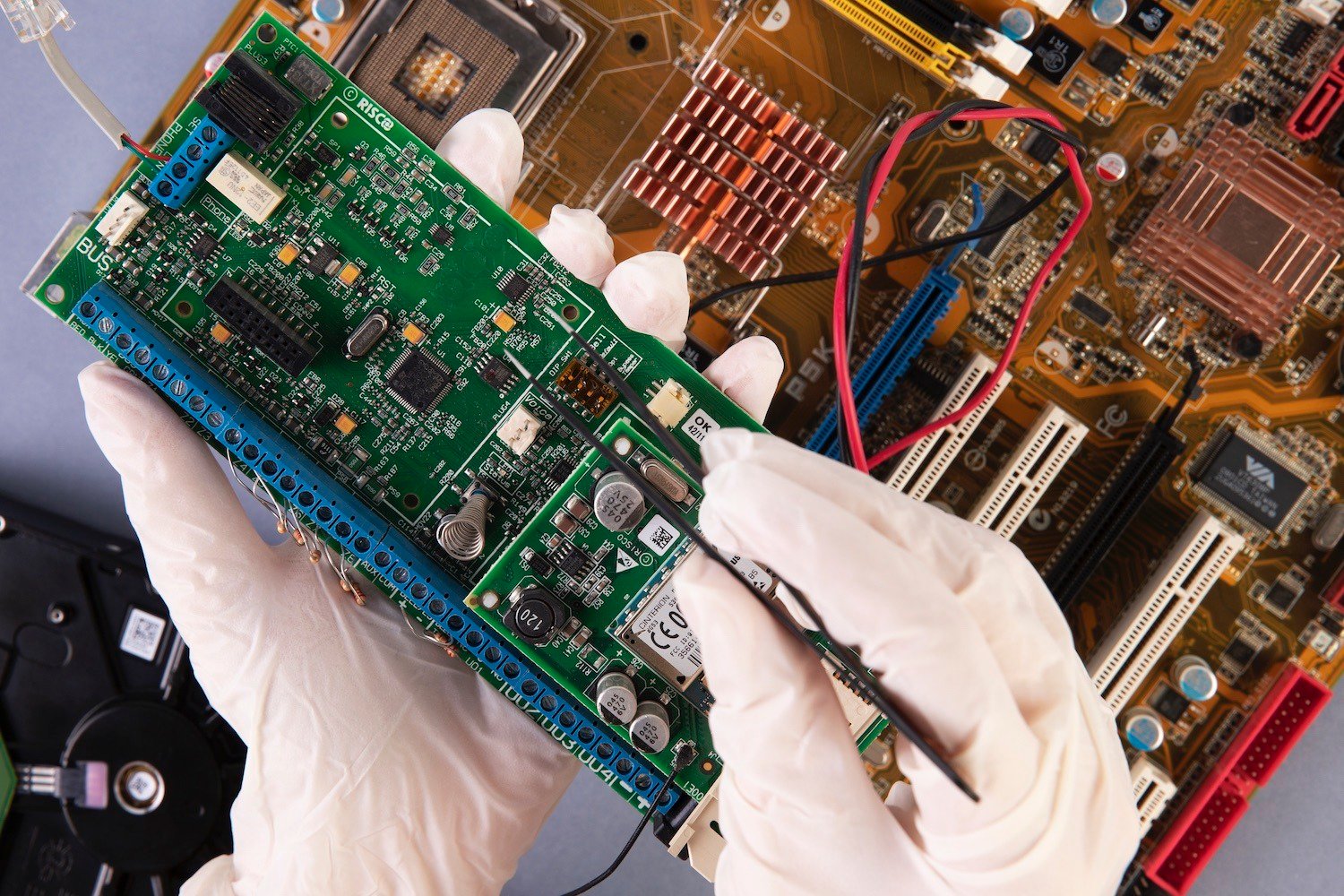

Guangzhou Huachuang Precision (HCJMPCBA) is a trusted one-stop provider of high-precision PCB assembly services, catering to global clients across diverse high-tech sectors—including industrial control, medical devices, smart manufacturing, AI, artificial intelligence, and autonomous driving. Backed by ISO 9001 & ISO 13485 certifications, we deliver end-to-end solutions spanning the entire electronics manufacturing lifecycle.

Full Turn-Key PCB Assembly

For full turn-key services, we manage every stage of the process: from PCB fabrication and procurement of 100% original components, to SMT (Surface Mount Technology) and DIP (Through-Hole Technology) assembly, rigorous testing (AOI, ICT, functional validation), Final product assembly, and even packaging & shipping. Our seamless workflow eliminates cross-vendor coordination, ensuring consistent quality and efficiency for clients.

Partial Turn-Key Flexibility

For partial turn-key needs, clients can provide PCBs or specific components—while we handle the remaining steps (sourcing missing parts, assembly processes, quality inspections). This flexibility allows us to align with diverse project requirements, whether you’re validating prototypes or scaling to mass production. We integrate precision engineering with tailored service to support your projects from concept to delivery.

Printed Circuit Board Assembly Services

- Full turnkey, partial turnkey, and consignment PCB assembly solutions

- Rapid prototyping to large-scale production PCB assembly

- SMT Assembly supporting 0201 components, BGA, QFN, and fine-pitch technologies

- Through-Hole Technology (THT) for connector, relay, and mixed-technology board assembly

- RoHS and non-RoHS compliant assembly options

- Functional testing, burn-in testing, and quality inspection

- Material sourcing & component procurement from authorized distributors

- Order tracking, shipping, and logistics management

- Custom cable harness assemblies (multiconductor cables, ribbon cables, wire harnesses)

Our one-stop PCB assembly solutions integrate cutting-edge technology and industry expertise to support your electronic projects—from prototype to mass production. Here’s how we deliver seamless value across every stage:

basic service

basic service Core PCB Fundamental Capabilities

Foundational PCB Services

PCB Fabrication:

Up to 32-layer precision manufacturing (supports HDI, rigid, rigid-flex designs). SMT Stencil Production: Laser-cut stencils for accurate SMT component placement. Electronic Components Sourcing: Full/partial procurement with 100% authentic parts (BOM management included).

Click here

Assembly Expertise

Assembly Expertise Professional Assembly Solutions

Assembly Expertise

Prototype PCB Assembly: Fast small-batch prototyping (no minimum order). Turnkey PCB Assembly: End-to-end service (fabrication → sourcing → SMT/DIP → testing) to simplify supply chains. Flex PCB Assembly: Specialized for flexible/rigid-flex circuits (optimized processes).

Click here

Value-Added Capabilities

Value-Added Capabilities In-Depth Technical Empowerment

Value-Added Capabilities

IC Programming: Online & offline programming for microcontrollers & ICs (covers diverse chip types for immediate integration). Comprehensive PCBA Testing: Multi-stage checks (ICT,AI AOI, X-ray, functional, aging tests) to ensure peak performance and durability,ensuring the optimal shipping effect.

Click here

PCBA Lead Time

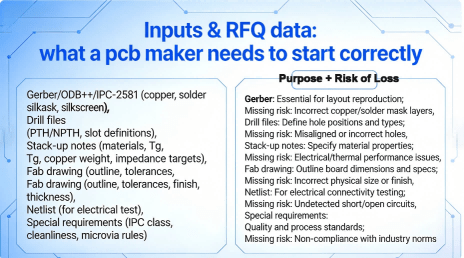

- Submit Gerber files, BOM (Bill of Materials), and project requirements to our team

- Our engineering team provides a detailed quote within 24 hours

- Confirm the quotation and proceed with purchase order & payment arrangement

- We arrange bare PCB manufacturing and component procurement

- Incoming material inspection and internal DFM (Design for Manufacturability) review

- For production orders, assembly (SMT/THT) is completed in 2–7 days based on order volume

- Comprehensive quality inspection (AOI, X-ray, manual visual check, functional testing)

- Global shipping via air/sea with delivery in as fast as 2 business days worldwide

- Gather customer feedback and provide post-delivery support

- Complete the order with full documentation and traceability

| Order Quantity | Standard Lead Time | Quick Turn Lead Time |

|---|---|---|

| QTY ≤ 50 | 5 Working Days | 1 Working Day |

| 50 < QTY < 100 | 8 Working Days | 3 Working Days |

| 100 < QTY < 1,000 | 10 Working Days | 5 Working Days |

| 1,000 < QTY < 10,000 | 15 Working Days | 7 Working Days |

| Capability | Standard |

|---|---|

| Certifications | ISO 9001:2015, ISO 13485 |

| Assembly Types | SMT, Through-Hole, Mixed Technology; Single/Double-Sided SMT/PTH |

| Component Sizes | Passive: down to 01005; Fine-pitch: down to 8 mils pitch |

| PCB Layers | Up to 32 layers (HDI, rigid, rigid-flex supported) |

| Lead Time | Prototyping: 3–7 days; Mass Production: 10–25+ days (per schedule) |

| Inspection & Testing | AOI, X-ray, ICT, Functional Testing, Aging Tests |

| Solder Type | Leaded, Lead-free (RoHS compliant) |

| File Formats | Gerber (RS-274X/274D), Eagle, DXF, DWG, Pick-and-Place Files |

| Rework Capability | BGA removal/replacement, SMT IR rework, Through-Hole rework stations |

SMT Engineering & Technical

- All Posts

- Blog

January 14, 2026/

A circuit card assembly is a complete electronic unit created when components are mounted, soldered, inspected, and tested on a…

January 10, 2026/

Learn the complete pcb manufacturing process in a clear, step-by-step way—from design review (DFM) and industrial pcb production planning to…

January 4, 2026/

Need to understand a 5 pin switch keyboard socket and how 3-pin vs 5-pin switches affect your keyboard PCB/PCBA build?…