10 Game‑Changing Steps to Flawless Custom PCB Design: From Cost Control to Cutting‑Edge Layouts

Discover a custom pcb design framework in 10 strategic steps—covering cost estimation, layout best

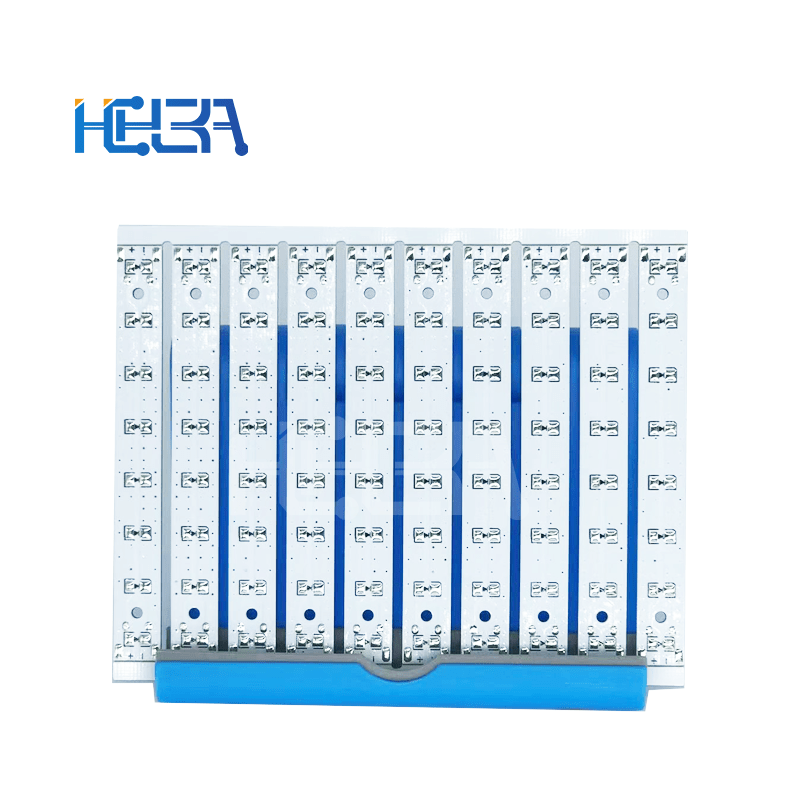

What Is an LED PCB? Ultimate Guide to PCB LED Design & Manufacturing

Table of Contents

Toggle

An LED PCB (Light Emitting Diode Printed Circuit Board) is a type of printed circuit board specifically designed to support LED components. Unlike standard PCBs, LED PCBs are engineered to handle the unique challenges posed by LEDs, such as heat dissipation and electrical connectivity. Understanding the intricacies of LED PCB design and manufacturing is essential for engineers and procurement professionals in the North American and European markets.

An LED PCB serves as the foundation for LED components, providing both electrical connections and thermal management. The primary functions of an LED PCB include:

1.1Electrical Connectivity: Ensuring proper electrical connections between the LED components and the power source.

1.2Thermal Management: Dissipating the heat generated by LEDs to prevent overheating and ensure longevity.

1.3Mechanical Support: Offering structural support to the LED components, maintaining their alignment and stability.

The design and material selection of an LED PCB are crucial in achieving these functions effectively.

The choice of material for an LED PCB significantly impacts its performance. Common materials include:

2.1Aluminum-Based PCBs: Known for their excellent thermal conductivity, making them ideal for high-power LED applications.

2.2Ceramic-Based PCBs: Offer superior electrical insulation and thermal performance, suitable for high-frequency and high-power applications.

2.3Fiberglass (FR-4): A cost-effective option for low-power LED applications, providing adequate electrical insulation and mechanical strength.

2.4Copper-Based PCBs: Provide the best thermal and electrical performance but are more costly.

Each material has its advantages and is selected based on the specific requirements of the LED application.

Designing an LED PCB involves several critical considerations:

3.1Thermal Management: Incorporating features like thermal vias, heat sinks, and copper pours to effectively dissipate heat.

3.2Electrical Design: Ensuring proper current distribution and minimizing voltage drops across the PCB.

3.3Mechanical Layout: Arranging components to optimize space and maintain structural integrity.

3.4Optical Design: Positioning LEDs to achieve desired light distribution and intensity.

Adhering to these design principles ensures the reliability and efficiency of the LED PCB.

The assembly process of an LED PCB typically involves the following steps:

4.1Solder Paste Application: Applying solder paste to the PCB pads where components will be placed.

4.2Component Placement: Using a pick-and-place machine to position LED components onto the PCB.

4.3Reflow Soldering: Heating the PCB to melt the solder paste, establishing electrical connections.

4.4Inspection and Testing: Conducting visual inspections and electrical tests to ensure the PCB functions correctly.

This process ensures that the LED PCB meets the required specifications and quality standards.

LED PCBs offer several benefits:

5.1Efficient Heat Dissipation: Materials like aluminum and copper effectively dissipate heat, enhancing the longevity of LEDs.

5.2Energy Efficiency: LEDs consume less power compared to traditional lighting solutions.

5.3Compact Design: LED PCBs allow for compact and flexible lighting solutions.

5.4Durability: Properly designed LED PCBs can withstand environmental stresses, ensuring long-term reliability.

These advantages make LED PCBs a preferred choice in various applications.

LED PCBs are utilized across various industries:

6.1Lighting Industry: Used in residential, commercial, and street lighting applications.

6.2Automotive Industry: Employed in vehicle lighting systems, including headlights and indicators.

6.3Medical Equipment: Integrated into medical devices requiring precise and reliable lighting.

6.4Consumer Electronics: Found in displays, indicators, and backlighting applications.

The versatility of LED PCBs makes them suitable for a wide range of applications.

What does PCB LED mean?

PCB LED refers to a printed circuit board designed specifically to support LED components, providing electrical connectivity and thermal management.

What are LED PCBs made of?

LED PCBs are typically made from materials like aluminum, ceramic, fiberglass (FR-4), or copper, chosen based on the thermal and electrical requirements of the application.

How to design an LED PCB board?

Designing an LED PCB involves considerations like thermal management, electrical design, component layout, and optical design to ensure optimal performance.

What is the LED PCB assembly process?

The assembly process includes solder paste application, component placement, reflow soldering, and inspection/testing to ensure the PCB functions correctly.

What are the benefits of PCB LED board?

Benefits include efficient heat dissipation, energy efficiency, compact design, and durability, making them suitable for various applications.

Understanding the intricacies of LED PCB design and manufacturing is crucial for engineers and procurement professionals. By selecting the appropriate materials and adhering to design principles, one can ensure the creation of reliable and efficient LED PCBs.

Discover a custom pcb design framework in 10 strategic steps—covering cost estimation, layout best

Introduction In the realm of modern electronics manufacturing,the assembly of printed circuit boards

A quick, clear explanation of the period formula in wave systems, showing how to calculate a wave’