Watts to Amps: 12 Expert Steps to Reliably Calculate Amps for PCB/PCBA Power Designs

For PCB/PCBA OEM engineers, procurement decision-makers, and cross-industry buyers, every component

How to Clean a PCBA Board Without Alcohol: Professional Methods for Electronics Manufacturing

Table of Contents

ToggleIn the world of PCBA manufacturing, using alcohol-based cleaners (such as high-purity isopropyl alcohol) has long been standard practice. However, many OEMs and contract manufacturers now face challenges when relying solely on alcohol: certain components are sensitive to solvent exposure, conformal coatings may degrade, regulatory or safety constraints may restrict alcohol use, and cost pressures push manufacturers to explore alternative methods. Therefore, discovering PCBA cleaning without alcohol workflows is becoming critical, especially for high-mix, high-reliability sectors like automotive, medical and aerospace. This is where HCJMPCBA’s experience in full-process PCBA manufacturing (SMT, through-hole, reflow soldering) helps guide you to the right solution.

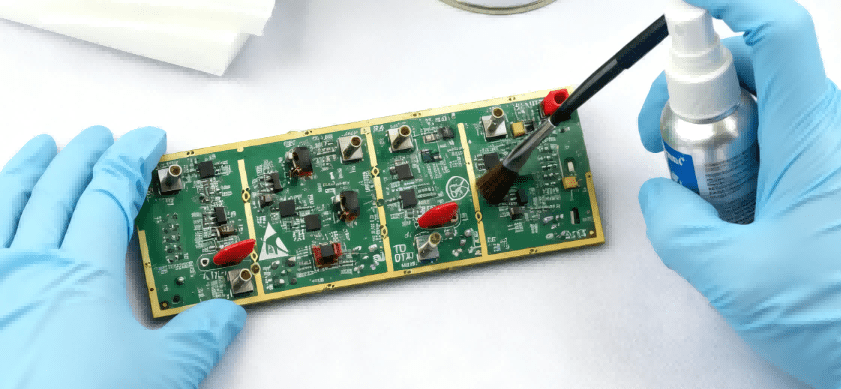

Hcjmpcba Clean A Printed Circuit Board

Water-based cleaning uses surfactant agents and de-ionized (DI) water to dissolve and flush away flux residues, solder paste residues, and ionic contaminants. For standard consumer and industrial control PCBA boards, this method strikes a strong balance of cost, safety and effectiveness.

Operation steps:

Wet the board with the solution.

Gently brush areas of solder and flux.

Rinse with clean DI water.

Dry via hot air (~50-60 °C) or clean compressed air.

Best suited for: mid-volume PCBA boards for control panels, consumer electronics.

Beware: incomplete drying = corrosion risk.

When working with high-density PCBA boards or process lines where solvent exposure must be minimized, solvent-free cleaning fluids (hydrocarbon, glycol-ether blends) offer high performance. They remove rosin-based or no-clean flux residues without the evaporation speed and volatility of 99% IPA.

Usage: Spray or application via bath; scrub with soft brush; rinse if required; dry properly.

Highly suitable for: automotive electronics, industrial control PCBA, where conformal coating follows cleaning.

Precaution: Ensure ventilation and environmental controls.

Mechanical cleaning (anti-static brushes, ultrasonic cleaning, soft wipe plus dry compressed air) is best used when chemical cleaning must be limited or when boards are large or low-density. For example, oversized PCBA boards for low-volume production.

Tools: ESD-safe brushes, ultrasonic tanks (if viable), dry-air blow-off.

Limitation: May leave micro-debris or require rework of residue in tight areas.

Ideal for: large format assemblies, mechanical control PCBA.

If your PCBA board uses no-clean flux in the SMT process, you may require minimal or no post-cleaning — provided the residue meets IPC-610 class requirements. This minimises cleaning cost and speed. However, for high-reliability PCBA (automotive, medical), even no-clean flux may benefit from removal to support conformal coating adhesion or high-frequency signal integrity.

Technique: Use process control, minimise flux volume, optimize reflow profile and optionally apply a light rinse or wipe.

Best for: general PCBA manufacturing where no-clean is accepted.

For high-density, mission-critical PCBA assemblies (e.g., European automotive ECU, medical modules, aerospace boards) the cleaning workflow may be bespoke: hybrid water/solvent systems, selective ultrasonic cleaning for first passes, final drying under nitrogen. At HCJMPCBA, we design custom workflows for such scenarios, ensuring traceability, compliance (ISO 9001/ISO 13485) and minimal risk.

When to use: multi-layer HDI PCBA > 10 layers, fine-pitch BGA, boards destined for harsh environments.

| Cleaning Method | Effectiveness | Cost | Suitable PCBA Type | Key Caution |

|---|---|---|---|---|

| Water-Based Solution | ★★★★☆ | Medium | Consumer / Industrial Control PCBA | Must ensure full drying |

| Solvent-Free Alternatives | ★★★★★ | High | Automotive / Aerospace / High-Reliability | Environment/ventilation required |

| Mechanical Cleaning Tools | ★★☆☆☆ | Low | Large format, low-density boards | May leave micro-debris |

| No-Clean Flux Process | ★★★☆☆ | Low | Standard PCBA manufacturing | Need to verify residue meets specs |

| Custom Hybrid Workflow | ★★★★★ | High | Mission-Critical PCBA (medical/automotive) | Requires detailed process control |

Hcjmpcba Pcb Cleaning

Disconnect board from power, remove battery or external connectors.

Select cleaning method based on board type and process (refer table).

If using water-based or solvent-free, apply spray or bath.

Gently brush using ESD-safe soft bristles across solder joints and flux areas.

If using mechanical only, apply compressed air or ultrasonic bath.

Inspect for white residue, flux stains or corrosion.

Dry thoroughly: hot air or drying oven, then final blast of clean compressed air.

For critical PCBA, apply conformal coating if required.

Document cleaning process and maintain traceability in QC records.

Q: Does alcohol-free cleaning affect board reliability?

A: When properly executed, alcohol-free cleaning (water-based, solvent-free or custom workflows) can meet or exceed reliability standards, especially when paired with correct drying and process control.

Q: Can I just leave no-clean flux residue and skip cleaning?

A: Yes, for many consumer PCBA this is acceptable. However, for high-reliability sectors you should evaluate surface insulation resistance (SIR), conformal coating adhesion, and long-term corrosion risk — cleaning is often preferred.

Q: What is the best cleaner for no-clean flux on HDI boards?

A: You might combine a flux-specific remover with a mild solvent-free cleaner, brush and dry under controlled conditions. Refer to trusted providers like ZESTRON. ZESTRON

Q: How do I pick the right method for my PCBA?

A: Consider the board complexity (layers, density, BGA count), application environment (automotive, outdoor, medical), flux type (rosin, no-clean, water-soluble) and budget. Use the table above to guide.

Selecting the right cleaning method for your PCBA board is not just a post-soldering activity — it’s an integral part of your manufacturing workflow that impacts yield, reliability, cost and traceability. Whether you opt for water-based cleaning, solvent-free alternatives, or a custom hybrid process, apply the technique that matches your board’s requirements, flux type and application. At HCJMPCBA, we combine full-service PCBA manufacturing (SMT, through-hole, reflow soldering) with cleanroom QC processes and transparent documentation to offer you reliable, scalable, global-ready solutions.

Learn more about our PCBA cleaning capabilities or full turnkey services — Contact Guangzhou Huachuang Precision Technology today for a consultation.

Learn more about PCBA services, please contact Guangzhou Huachuang Precision Technology.

For PCB/PCBA OEM engineers, procurement decision-makers, and cross-industry buyers, every component

A flame sensor is a critical safety device that detects flame presence to prevent gas leaks and expl

PCB vs PCBA explained clearly: Learn what a PCB is, how a PCBA differs, and when each makes sense. G