Combatting Component Misplacement in PCBA: Advanced Solutions for High-Quality PCB Manufacturing

In the process of PCB Assembly (PCBA), component misplacement is one of the primary issues affecting

Engineer’s Perspective — Selecting & Applying Circuit Board Components for Performance & Reliability

Table of Contents

ToggleA bare PCB (printed circuit board) offers only the structural substrate — copper traces, vias, solder mask, and board layers. To transform that inert board into a fully functional electronic module, one must populate it with circuit board components: the resistors, capacitors, diodes, integrated circuits (ICs), connectors, and more that enable power regulation, signal processing, connectivity and protection.

For OEM engineers, procurement specialists, and product designers — especially those targeting demanding markets in North America and Europe — the choice and quality of these components directly influence the performance, reliability, cost, and supply-chain stability of the final PCBA (printed circuit board assembly). At HCJMPCBA, our philosophy is guided by “technical fit + supply-chain optimization”: we don’t just assemble boards — we help select and source optimal components, manage procurement risks, and ensure consistent quality across batches.

This guide walks you through the classification, function, selection, and sourcing of circuit board components — from basic resistors to complex ICs and connectors — and shows how components, PCB layout, and assembly interact to form a reliable electronic system.

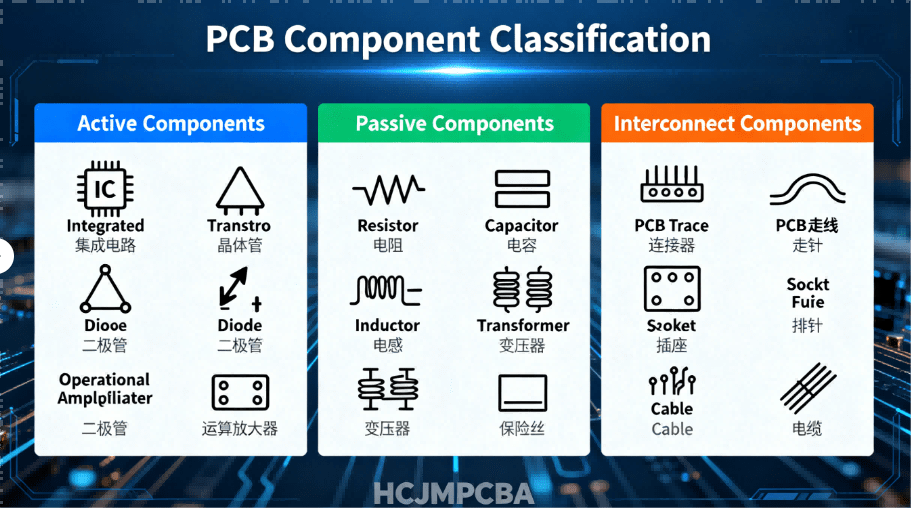

Active components are the brain and logic units of any functional circuit. They require an external power supply (voltage or current) to operate, and can amplify, switch, or process electrical signals. Without them, a PCB is little more than a wired board

Common types of active components include:

Integrated Circuits (ICs) — microcontrollers (MCUs), logic chips, analog or mixed-signal chips, power management ICs, etc. These often integrate many transistors, capacitors, and resistors into a single package for functionality, miniaturization, and stability.

Transistors and diodes — used for switching, signal amplification, rectification, protection, and voltage regulation.

Voltage regulators, power-management ICs, oscillators/crystals — ensure stable power, clock signals or timing references required for system operation.

Active components define the core logic, processing, control, and dynamic behavior on a PCB — essentially dictating whether the board acts as a simple power distribution board, a sensor interface, a communication module, or a full-fledged embedded system.

Passive components, unlike active ones, do not require an independent power source. They cannot amplify signals, but they are crucial for controlling current, storing energy, filtering noise, and stabilizing voltages.

Common passive components include:

Resistors — limit or regulate current flow, divide voltages, set bias conditions, and protect sensitive components. Resistors are perhaps the most ubiquitous circuit board components.

Capacitors — store and release charge, provide decoupling and filtering, smooth power supply ripple, and serve as timing elements. Depending on their type (ceramic, tantalum, electrolytic), they fulfill different roles from high-frequency decoupling to bulk energy storage.

Inductors / Chokes / Ferrite beads / Magnetic components — used in power supplies, filters, EMI suppression, and as part of signal conditioning.

Other passive / protective components: fuses, varistors, transient voltage suppressors (TVS), crystals / oscillators (timing), filters — each serving specialized roles like protection, frequency reference, or signal conditioning.

These passive parts form the backbone that ensures power stability, signal integrity, noise suppression, and circuit protection.

Beyond purely electrical or passive/active classification, many PCBs require electromechanical or interconnect components — interfaces between the PCB and the external world, or mechanisms for mechanical control. These include:

Connectors, sockets, headers, wire-to-board / board-to-board connectors — enabling modularity, external interfaces (power input, data ports, I/O), and ease of assembly / maintenance.

Switches, relays, sockets, terminals, cable harnesses, board mount connectors — for power control, user interaction, modular component integration, and system-level connectivity.

Mechanical supports, mounting holes, grounding points, shielding cans, heatsinks (if thermal dissipation needed) — to meet mechanical, thermal, and environmental robustness requirements, especially for industrial, automotive, or rugged-use PCBA.

These interconnect and mechanical components often determine how the PCB integrates into the final product’s enclosure, interacts with other modules, and endures mechanical stress or environmental conditions.

Hcjmpcba Pcb Component Classification Diagram

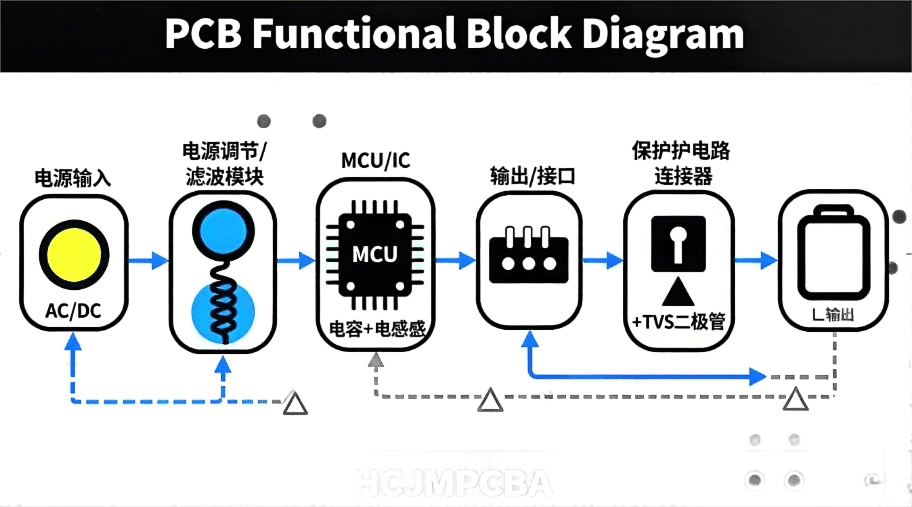

A blank PCB board — with just copper traces, solder mask, vias, and internal layers — serves only as a wiring canvas and mechanical substrate. The real “intelligence” comes from populating it with components.

Here’s how components integrate to bring a PCB to life:

Power management & regulation

A power input connector (or battery header) brings in raw voltage. Passive parts (capacitors, inductors) stabilize and filter the supply; voltage regulators (active components) ensure the voltage is appropriate for sensitive ICs. Decoupling capacitors near IC power pins eliminate noise, and resistors may set reference voltages or current limits.

Signal processing & control

Digital or analog ICs (microcontrollers, logic, power-management ICs) perform computation, control, or data processing. Passive components (resistors, capacitors) around them form filters, bias networks, timing circuits (oscillators/crystals) or protection networks.

Interface & connectivity

Connectors, headers, sockets, and connectors allow external modules, sensors, cables, or user interfaces to connect. Electromechanical parts help ensure secure connection, mechanical strength, and modular design.

Protection & stability

Protective components — e.g., diodes for reverse polarity, TVS / varistors for surge protection, fuses — safeguard against incorrect wiring, voltage spikes, or EMI. Passive filters (inductors + capacitors) clean signal lines and stabilize analog / RF circuits.

Thus, a functioning PCB is a delicate orchestration where each component plays a defined role. The choice, quality, and integration of these components — along with proper layout, soldering, and assembly — will determine the end-product’s performance, reliability, and compliance.

Hcjmpcba Functional Module Schematic Diagram

Successful PCBA design and manufacturing hinges on correct component selection. From the engineer’s side, the following principles guide selection:

1. Matching Specifications: Electrical, Mechanical and Environmental

Electrical parameters: For each component, ensure that voltage rating, current capacity, frequency response, tolerance (for resistors / capacitors), ESR/ESL (for capacitors/inductors), switching speed (for active components), and signal integrity (for high-speed / RF circuits) match design requirements.

Package / footprint / assembly compatibility: Depending on assembly method (SMT or through-hole), board thickness and pad design, selected components must be compatible with your PCB design rules. For example, SMD passive components (e.g., 0603, 0402, 0201) require accurate stencil design and pick-and-place precision.

Environmental & reliability requirements: For industrial, automotive or harsh-environment products, components should meet temperature range (e.g., –40 °C to +85 °C or more), vibration resistance, humidity tolerance, and possibly EMI / EMC compliance. Components should have suitable derating margin for long-term stability.

2. Key Component Selection Examples

ICs (microcontrollers, logic chips, power ICs): Choose appropriate package type (e.g., QFN, BGA, QFP) based on board space, thermal dissipation needs, testability and reworkability. High-pin-count BGAs may offer compactness but complicate inspection and rework; simpler QFP / QFN may ease assembly but require footprint precision.

Passive components: For resistors — choose proper tolerance (±1%, ±5%) and power rating; for capacitors — consider dielectric type (ceramic MLCC for high-frequency decoupling, tantalum or electrolytic for bulk filtering), voltage rating, ESR/ESL, and size; for inductors / filters — choose based on current rating, saturation current, and frequency band.

Connectors / mechanical parts: Select based on mating cycles (durability), locking mechanism (secure connection), environmental sealing (for outdoor / industrial use), and board-to-wire or board-to-board compatibility.

3. Component Identification & Troubleshooting Basics

In engineering and production phases, being able to identify components and diagnose faults is essential:

Identification: Through reference designators on PCB silk-screen (e.g., R for resistor, C for capacitor, U or IC for integrated circuits, J or CON for connectors), along with package markings or part-numbers.

Failure diagnosis: Passive component failure may cause open circuits or drift (e.g., resistor value drift, capacitor leakage/ESR increase), while active component failure may cause logic errors, power faults, or thermal runaway. Connector failures often show as intermittent contact or disconnections.

From a procurement or supply-chain point of view, efficient sourcing of circuit board components is just as critical as technical design. A robust procurement strategy balances cost, quality, and availability.

Standard parts vs custom / specialized parts: Standard passive components (resistors, capacitors, inductors) and common connector types usually have stable supply and favorable pricing when purchased in bulk. In contrast, specialized parts (high-speed ICs, custom connectors, rare components) may have higher costs and longer lead times.

Quality control and traceability: Components should come from verified suppliers, with appropriate certifications (RoHS, CE / UL / VDE / TUV as needed), and traceability to avoid counterfeit or sub-standard parts.

Stock strategy and lead-time management: For core or long-lead components (ICs, connectors, custom parts), maintaining safety stock or dual-supplier sourcing helps shield production from supply chain disruptions.

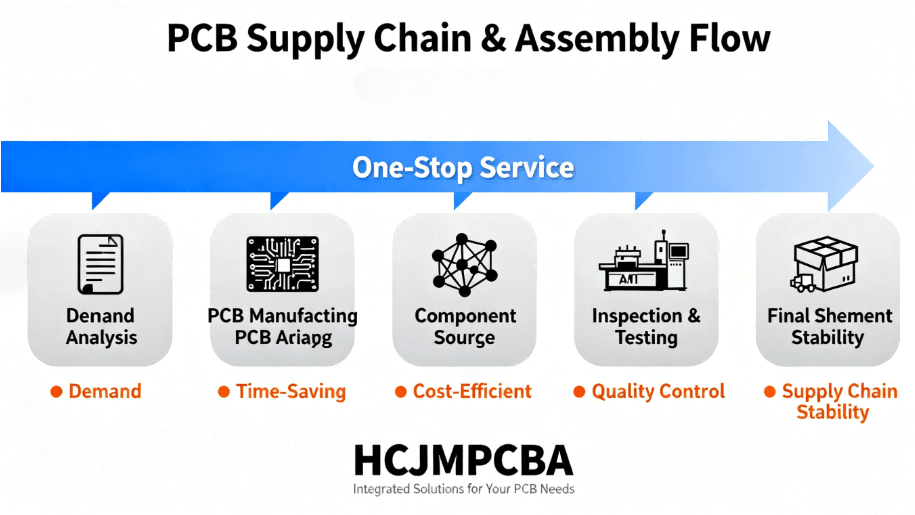

For many customers, coordinating separate PCB fabrication, component sourcing, and PCBA assembly can be time-consuming and risky. That’s where HCJMPCBA’s one-stop service delivers real value:

We combine PCB manufacturing, component procurement, SMT / THT assembly and inspection — reducing supplier coordination overhead and ensuring component-board compatibility.

Our procurement team handles sourcing from reliable vendors (including original manufacturers), oversees certificate compliance, component traceability, and BOM management.

Integrated supply and assembly reduces lead time, lowers risk of mismatches, ensures quality control, and often reduces overall cost compared to managing multiple suppliers.

Hcjmpcba Supply Chain Flow Chart

As electronics evolve rapidly, the industry faces several challenges — but with the right capabilities, these can be managed. Here are some big trends and our strategies.

Miniaturization & high-density assembly (01005, 0201 passives; fine-pitch BGAs / QFNs)

These require extremely precise PCB layout, accurate stencil and solder paste control, high-precision pick-and-place machines, and thorough inspection (SPI / AOI / X-ray).

HCJMPCBA solution: we have high-speed SMT lines with fine-pitch capability, precise tooling, and in-house inspection equipment to ensure yield and reliability.

Reliability & environmental robustness (temperature extremes, vibration, EMI, long lifespan)

Quality components (with proper derating), careful layout (ground / power planes, decoupling), and robust assembly practices are needed.

HCJMPCBA supports material and component selection for harsh environments, supports thermal/ vibration / EMI compliance testing, and monitors lifecycle performance.

Component shortages and supply chain volatility

Especially for ICs, connectors, or custom-spec parts — lead times may be long or unpredictable.

HCJMPCBA mitigates risk by maintaining safety stocks, sourcing from multiple verified vendors, and maintaining a database of alternative / equivalent components for substitution when necessary.

Regulatory compliance & certification demands (RoHS / REACH / environmental / safety standards)

Components must meet regulatory requirements, especially for EU / NA markets.

HCJMPCBA ensures all sourced components are compliant, documents certifications, and manages BOM traceability for audits and compliance needs.

Looking forward, several trends are shaping how circuit board components—and the PCBs themselves—evolve:

Higher integration: SiP (System-in-Package) / multi-function modules — more functions packed into single packages, reducing board size and assembly complexity.

Smart & IoT components: sensor-integrated modules, flexible PCBs, embedded components (e.g., MEMS sensors, wireless modules) — enabling more compact, intelligent, connected devices.

Green electronics: increasing demand for lead-free, halogen-free, RoHS / REACH–compliant components and materials.

Supply chain transparency & lifecycle management: traceability, component origin documentation, and end-of-life (EOL) planning or recycling — important for compliance and sustainability.

As a forward-looking EMS provider, HCJMPCBA is investing in component sourcing networks, eco-friendly materials, SiP / embedded-module assembly capabilities, and lifecycle support — to meet the next generation of electronics demands.

Understanding what is inside a circuit board — from passive resistors and capacitors, to powerful ICs, connectors, and electromechanical parts — is critical for designing, manufacturing, and delivering reliable electronics. The right combination of components, PCB design, assembly process, and supply-chain management determines whether a product succeeds or fails.

HCJMPCBA offers more than just PCB fabrication or SMT assembly — we provide a full-chain solution: component sourcing, procurement, BOM management, high-precision assembly, inspection, and quality control. For engineers seeking to optimize design and reliability, and procurement professionals aiming for cost-effective, compliant, and stable supply, partnering with HCJMPCBA means less hassle, higher confidence, and faster time-to-market.

Contact HCJMPCBA today to get your custom PCB & component sourcing & assembly needs fulfilled.

In the process of PCB Assembly (PCBA), component misplacement is one of the primary issues affecting

Discover what a 10k resistor is, how to read its color bands, and why this fundamental component is

Learn how to use a multimeter correctly and safely to test voltage, resistance, continuity and curre