7-Fundamental Stages of the PCB Manufacturing Process: A Precision Guide by HCJMPCBA

Explore the PCB Manufacturing Process from design and imaging to etching, drilling, plating, and fin

How to Use a Multimeter for PCB/PCBA: A Complete Guide for Engineers & Buyers

Table of Contents

ToggleIn PCB/PCBA manufacturing and assembly, a simple multimeter (digital multimeter, DMM) remains one of the most essential tools. Whether it’s for quality inspection, fault diagnosis, or production spot-checks, knowing how to use a multimeter correctly can make the difference between a reliable board and a faulty one.

For OEM engineers, procurement professionals, final-product buyers or cross-industry purchasers, multimeter skills help ensure quality, reduce rework, and increase yield. For PCBA shops like HCJMPCBA, integrating multimeter-based checks into quality control (QC) — for solder joints, component placement, continuity, power rails, and currents — contributes to high reliability and consistent output.

This article covers everything: from multimeter basics and safety, to step-by-step instructions for PCB/PCBA-specific tests, to tips on choosing the right multimeter for different use cases.

A multimeter, often called a DMM (Digital Multimeter), is a versatile measuring instrument that can test voltage (AC/DC), resistance (Ω), continuity, current (A / mA / μA) — sometimes also capacitance or diode-test functions.

In the context of PCBA work, a multimeter becomes indispensable for:

Verifying solder joints & PCB trace continuity.

Checking that components (resistors, diodes, connectors) are functioning / within spec.

Confirming power rails, supply voltages, current draw.

Locating shorts, opens, or other defects during inspection or post-repair testing.

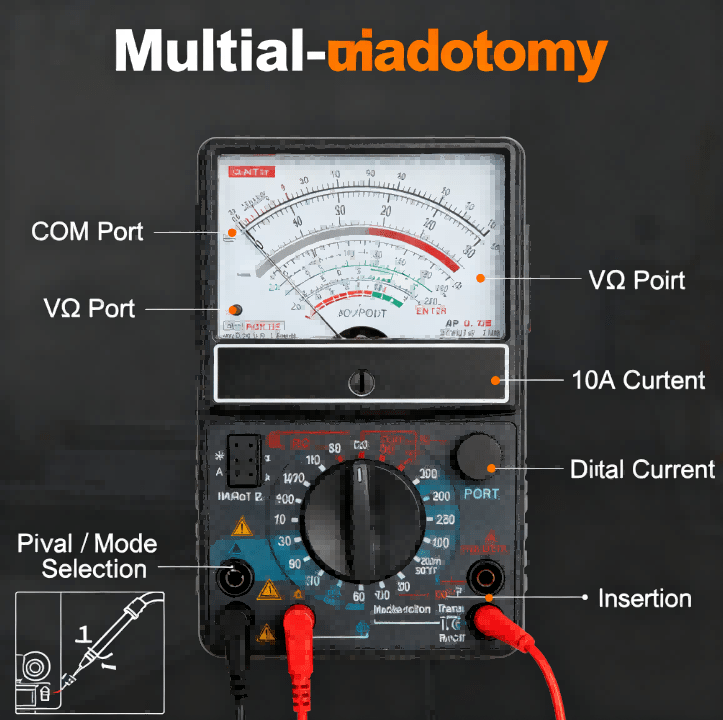

Typical multimeter components:

Display: LCD screen showing numeric reading, units (V, Ω, A), sometimes icons (continuity, diode, etc.)

Selection knob (rotary switch): to choose the mode — e.g. DCV, ACV, Ω (resistance), continuity (beep), current (A / mA) etc.

Ports / Sockets: usually “COM” (common/ground), “VΩ” (voltage / resistance / continuity), “mA/µA” (for small currents), and “10A” (high current) ports.

Test leads / probes: sharp-tip or fine-tip probes help when testing small SMD pads or traces on PCB. For sensitive PCBA work, fine-tip and ideally ESD-safe probes are recommended to avoid damaging components.

When selecting a multimeter for PCB/PCBA work, it’s beneficial to have a model with: good resolution/accuracy, clear dial, proper ports for current & voltage, and fine-tip probes or options to attach them.

Before diving into testing, always power off the PCB, discharge capacitors if any, and take ESD-safe precautions. That protects both the board and your multimeter.

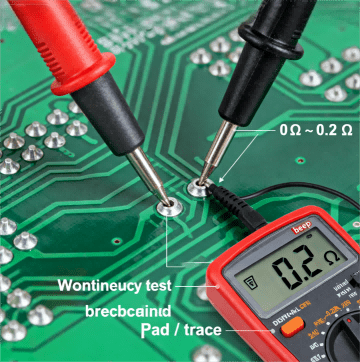

Turn the multimeter’s dial to the continuity mode (often shown as a 🔔 or speaker icon).

Insert the black probe into COM, red probe into VΩ port.

Touch the two probes together — you should hear a beep (confirming the meter works).

Then place probes on two points you want to test (e.g. two ends of a trace, two solder pads).

If multimeter beeps / shows very low resistance (close to 0 Ω) → the circuit is continuous (good).

If no beep / “OL” / high resistance → open circuit / broken trace / no continuity.

This method is ideal to verify that solder joints are solid, that vias or traces connect properly, or to detect broken / disconnected nets on a PCB. It’s a quick and efficient test for basic QC or functional check.

Hcjmpcba Multimeter Anatomy Dial & Ports Layout

Set multimeter to Ω (Ohm) mode. If meter is manual-range, pick a suitable range; auto-range meters adjust automatically.

With the circuit powered off, place probes across the component whose resistance you want to measure (e.g. resistor, resistor networks, fuse). Polarity does not matter.

Compare displayed value to component spec (from BOM / datasheet). If within tolerance (e.g. ±5%, ±1%), component is OK; if significantly off or reads “OL,” the component or solder joint may be faulty.

This method is useful for checking passive components, fuses, shorts, or whether a particular network is intact — especially before powering up a board to avoid damage.

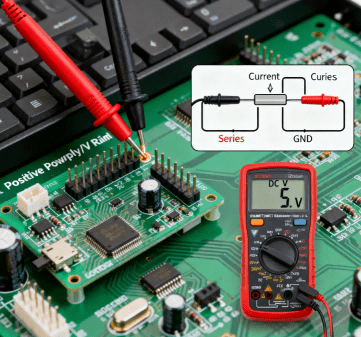

To check supply rails, power lines or output voltages after assembly:

Turn dial to DC V (or AC V if needed). Insert black probe to COM, red probe to VΩ.

Probe between ground (GND) and the point whose voltage you want to check. For example, check if 5 V line is present, or if output voltage from regulator is correct.

Compare measured voltage with expected value (from design / datasheet). Deviations beyond tolerance may indicate power issues, short circuits, or soldering defects.

Care must be taken to avoid probing two live points that are not intended as ground and Vcc, to prevent short-circuits or damaging sensitive components.

Hcjmpcba Continuity Test On Pcb Pad Trace

For measuring current draw (e.g. in functional testing, standby current test, or QA load testing):

Turn dial to appropriate current mode (mA/µA or 10A depending on expected current).

Move red lead to appropriate port (mA or 10A). Leave black in COM.

Break the circuit — multimeter must be inserted in series with load (not in parallel).

Power the circuit, measure current. Compare with expected current draw from design.

This test helps verify that there are no unexpected short circuits, high leakage, or power consumption anomalies before finalizing assembly or shipping.

Hcjmpcba Voltage & Current Testing On Assembled Pcb

When choosing a multimeter for PCB/PCBA use, consider the following criteria:

Accuracy & Resolution — To detect small resistance differences or low-voltage deviations, choose a meter with reasonable accuracy (±1% or better if budget allows).

Port / Probe Options — Having COM, VΩ, mA/µA, 10A ports is essential; fine-tip & ESD-safe probes help for dense PCB.

Auto-Range vs Manual Range — Auto-range simplifies quick testing across multiple ranges; useful in QA/production environment.

Safety & Input Protection — A good DMM should comply with safety standards (e.g. IEC 61010), have overload protection, and safe probe insulation — especially when testing boards with power.

Portability & Ease of Use — For field inspection, incoming QC, or small-lot testing, compact meters with clear displays are more practical.

Depending on roles:

PCB/PCBA engineers (in production / QC) — industrial-grade DMM with fine probes, auto-range, current measurement;

Procurement / QA / purchasers — mid-range DMM with enough functionality and safety certifications, balancing cost vs flexibility;

End customers / basic QC users — basic digital multimeter covering DC voltage, continuity, resistance, optionally current — sufficient for board acceptance check.

As PCBA complexity increases (fine-pitch components, high-density boards, multilayer traces), multimeter remains a useful baseline tool — especially combined with automated inspection tools (AOI, X-Ray) or test fixtures.

Batch testing with test jigs + multimeter: For production lot testing (e.g. continuity / shorts / basic power-on check), use a custom test fixture that exposes test points; multimeter (or array of meters) can quickly validate hundreds of boards without visual inspection.

Post-repair / rework verification: After rework or repair on a PCB, confirm continuity, resistance, power rails and current to ensure repair integrity before powering up.

Pre-shipment QA / incoming inspection: For components / assembled boards, use multimeter to spot-check solder joints, connectors, and power rails — as a first-pass QA before full test.

These advanced usage scenarios help reduce rework, catch latent defects early, and improve overall yield — important for OEM, contract manufacturing, or bulk PCBA orders.

Mastering how to use a multimeter — not just in general electronics, but tailored specifically for PCB/PCBA — is a foundational skill for engineers, quality inspectors, procurement professionals, and buyers. Proper use, combined with the right multimeter for the job, ensures:

Reliable solder joints and trace integrity

Accurate component verification (resistance, continuity, power rails)

Early detection of shorts, opens, faulty components

Safer, faster QC / incoming testing / batch inspection

Reduced defects, better yield, and higher product reliability

Call to Action: For professional PCB/PCBA assembly and quality-controlled services, please contact HCJMPCBA — we’re ready to support your next project with reliable production, testing, and delivery.

Explore the PCB Manufacturing Process from design and imaging to etching, drilling, plating, and fin

Explore the definitive guide to pcb assembly—from turnkey pcb assembly to smt pcb assembly and thr

Guangzhou Huachuang Precision Technology Co., Ltd. has achieved remarkable success in various projec