HCJMPCBA’s ISO 13485 Certified Medical PCB Assembly: 10+ Years of 99.99% Reliability for Life-Saving Devices

Discover HCJMPCBA’s 13485 medical manufacturing excellence in medical PCB assembly. Learn about me

10 Essential Things You Need to Know About SMD 0805: Can You Probe 0805 & More for PCBA Projects

Table of Contents

ToggleSurface Mount Device (SMD) packages such as 0805 have become ubiquitous in modern PCB assembly because they balance compact size, power handling, and manufacturability. For OEM engineers, procurement decision-makers, and cross-industry buyers, questions often arise like: What exactly is an SMD 0805 resistor? How much power can an 0805 handle? Can you reliably probe 0805 components during testing without damage?

This comprehensive guide answers those questions and more — it explains what SMD 0805 is, essential parameters such as size and power rating, proven methods for probing these tiny parts, and how HCJMPCBA manages 0805 components throughout PCBA design, test, and production cycle to reduce risk and improve reliability.

Throughout the article, we’ll use structured sections, clear definitions, practical testing techniques, and expert steps to support engineers and buyers in making informed PCBA decisions.

Natural inclusion of keywords like can you probe 0805, 0805 resistor, 0805 resistor dimensions, and probe measurements ensures clarity and SEO value for search intent focused on How-to, Component Specs, and Testing Techniques.

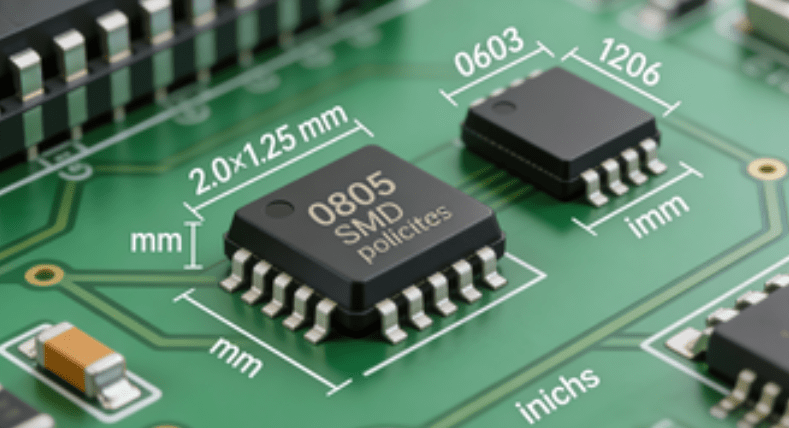

An SMD 0805 refers to a surface mount package with an imperial code of “0805”—roughly 0.08 inches by 0.05 inches (≈ 2.0 mm × 1.25 mm) in length and width. This size strikes a balance between compact layout and practical handling in PCBA manufacturing.

The “0805” code originated from imperial measurements; it is often translated into metric footprint names like 2012 but engineers widely use 0805 as the standard naming convention in both resistor and capacitor catalogs. Unit Circuits

Why 0805 Matters in PCBA:

Larger than ultra-compact formats like 0603 — making manual inspection and rework easier

Smaller than 1206 — saving precious board space

Compatible with automated pick-and-place machines at high throughput

This makes 0805 SMD parts ideal for medium-power signal lines, decoupling functions, and wide applications from IoT modules to industrial controllers.

Within the 0805 footprint, multiple discrete components exist — including:

0805 Resistors & Capacitors used for current limiting, voltage division, and signal conditioning

Cap 0805 ceramics for decoupling and noise suppression

Inductors, diodes, and small network modules that adhere to the same footprint standard

HCJMPCBA maintains a verified component library with 5,000+ 0805 parts ready for use in production, minimizing sourcing delays and strengthening supply reliability.

A typical 0805 resistor measures:

Length: ~2.0 mm

Width: ~1.25 mm

Thickness: Standard small-signal profile

These dimensions enable reliable soldering and testing without compromising board density. Unit Circuits

Power rating is a critical specification that defines how much energy a resistor can safely dissipate. For standard 0805 resistors:

Continuous power rating often lies around 0.125W (1/8W) for general thick-film parts.

Derated ratings (e.g., up to 0.25W) may be specified depending on design and manufacturer.

Some high-power 0805 variants push up toward 0.33W or even 0.5W for specialized thick-film versions, particularly automotive-grade AEC-Q200 resistors.

Note: manufacturers’ datasheets always provide exact values; generic values vary by composition and substrate.

What Does This Mean for PCBA Designers?

Choosing the correct power rating is indispensable, especially where heat buildup may degrade component life or disrupt surrounding components on the board. For robust performance, always pick an 0805 part with a power rating that exceeds the expected load and ensure ambient derating curves are respected.

If an 0805 resistor power rating is undersized for the application, the component may overheat, drift in resistance, or even fail. Accurate sizing prevents:

Thermal stress and board warping

Signal integrity issues due to resistor drift

Overload and cascading component failure

HCJMPCBA’s engineers proactively cross-verify resistor power ratings with schematic requirements during the design phase — helping clients avoid costly rework and burn-in failures in critical applications.

Understanding can you probe 0805 is essential because small SMD components lack traditional test points and are held rigidly by solder. Probing requires deliberate technique and proper tooling to avoid damage.

Because 0805 parts sit flush on the PCB with tiny terminations, the main challenges include:

Tiny footprint makes contact difficult without slipping

Standard hook tips may not grab the component’s terminal

Excessive force during measurement can lift solder joints or distort the part

This is why intentional probe measurements must use suitable tools to guarantee accurate, repeatable results.

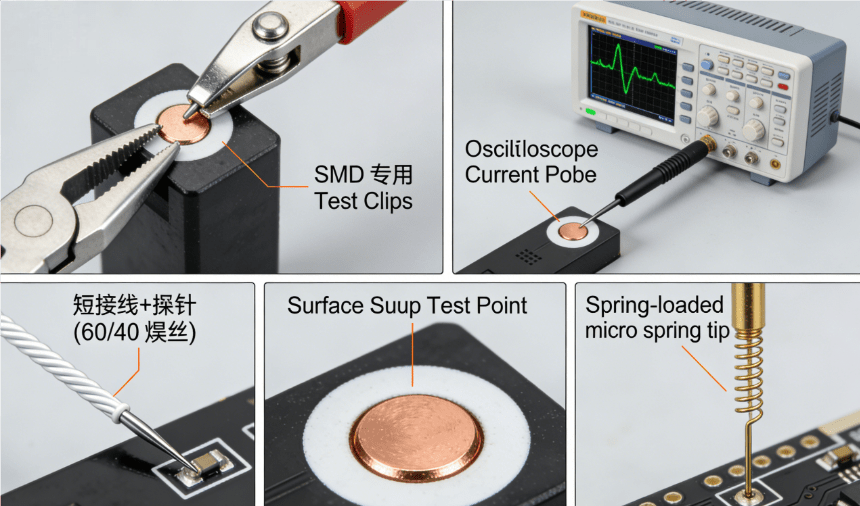

5 Common 0805 Probing Methods Hcjmpcba

0805 Smd Hcjmpcba

Below are practical and reliable ways to perform probe measurements around 0805 SMD parts:

Spring-loaded or micro gripper SMD test clips offer secure contact on an 0805 pad or side termination. These clips help ensure repeatable measurements when capturing the voltage across 0805 components. Specialized spring tips and grippers are available for tight spaces.

For more accurate oscilloscope probing:

🔹 Place a short, heavy-gauge solder on each side of the 0805 component

🔹 Solder a short loop of wire (e.g., Kynar/28AWG) to the soldered ends

🔹 Clip the oscilloscope probe to the wire for a stable measurement

Using 60/40 solder (60% tin, 40% lead) helps because its lower melting point (≈183°C) reduces the risk of thermal damage while forming a reliable pad for test leads.

High-precision micro probes with spring-loaded tips are ideal for small surface mount test points. These may include gold-plated spring needle tips that resist slipping — especially useful in production labs.

During PCB layout stage, add dedicated surface mount test points near critical signals. These test pads (sometimes as small as 0.05 in) provide reliable contact for probes and allow engineers to attach oscilloscope leads without touching the tiny 0805 parts directly.

Where direct contact to resistor terminals is impractical, use current probes to measure signal or current flow. A current probe clamps around a lead or wire to provide measurement without physically touching the component, especially valuable for high-frequency or dynamic current testing. Oscilloscope probe accessories (such as differential or low-capacitance probes) further enhance signal fidelity.

HCJMPCBA follows a structured process for 0805 signal and component testing:

Tool Selection: Choose the appropriate tooling (SMD test clip, spring probe, or current probe).

Secure Setup: Mount PCB on anti-static workbench and use test points for ground reference.

Probe Attachment: Connect the chosen probe to the test fixture or clip.

Record & Validate: Perform measurement with oscilloscope or DMM and compare results with design specs.

Document Results: Log test data and attach to quality reports.

This SOP ensures high-confidence 0805 probing with minimal risk of damage or false readings.

Issue: Clips slip off or cause inconsistent contact

Solution: Use micro spring probes or dedicated SMT test points; secure wires before probing.

Issue: Probe noise distorts waveform

Solution: Use shielded cables, attenuated probes, or differential probes to reduce noise.

Issue: Counterfeit or non-spec’d 0805 parts

Solution: HCJMPCBA sources from authorized distributors (Digi-Key, Mouser) with traceable certifications.

Issue: Poor solder joint formation at high thermal loads

Solution: Use appropriate 60/40 reflow profiles and perform thermal cycling tests to validate assembly integrity.

Expertise in Miniaturized PCBA: 20+ years of experience with high-density designs

Advanced Test Lab: Oscilloscopes, micro probes, and current probe instruments for accurate SMD measurements

Clear Documentation & Traceability: Clients receive detailed reports on probe measurements, solder profiles, and component performance

Understanding **what SMD 0805 is, typical power ratings (like ~0.125W), how to interpret 0805 resistor sizes, and techniques for can you probe 0805 SMD components is essential to success in modern electronics design and manufacturing. With the right test points, clips, probes, and HCJMPCBA’s structured SOPs, engineers and procurement teams can reduce risk, improve quality, and confidently bring products to market.

Discover HCJMPCBA’s 13485 medical manufacturing excellence in medical PCB assembly. Learn about me

Understand the core manufacturing processes and component composition of circuit card assembly (PCBA

Discover what a blank PCB and parts are—you'll learn about blank PCB board, bare printed circuit b