HCJMPCBA’s 10-Step Essential Guide: What Is a Circuit Diagram & How to Read and Design PCB Schematics for Excellence

Discover what a circuit diagram is and how to read or design a clear pcb schematic step-by-step. Und

13 Practical, Cost-Focused Facts About Circuit Card Assembly: From Clear Basics to Real-World Assembly Pricing (Including V-One PCB Printer Optimization)

Table of Contents

ToggleIn product development, the printed circuit board is only a promise. The promise becomes a working electronic unit during circuit card assembly—when components are placed, solder joints are created, and the board is verified through inspection and testing.

This is also the moment when “reasonable estimates” can turn into missed budgets. Two suppliers can quote the same design and still land far apart because assembly pricing is shaped by variables that are easy to overlook: component availability, the number of unique parts, the amount of manual work, the depth of testing, and the expected yield.

This article follows a simple logic (similar to the best cost-focused guides):

1.define the terms clearly,

2.explain the process step by step,

3.break cost into auditable line items, and

4.show how to request an accurate quote and reduce risk—without chasing “cheap pcb suppliers” that create expensive delays later.

To keep the language usable for both engineers and procurement teams, technical terms are explained in plain words, and every checklist is written so it can be copied into a request for quotation.

Hcjmpcba Circuit Card Assembly Vs Pcb Vs Assembly

A circuit card assembly is a completed electronic unit built by assembling components onto a printed circuit board and verifying it through inspection and testing. In practical terms, it is the point where a bare board becomes a functional unit that can be installed into a larger product.

A circuit card assembly usually includes:

a populated board (components soldered in place),

identification (part number, revision, and often a serial label),

inspection evidence (for example, inspection records or defect disposition),

test evidence (for example, pass/fail results or measured values),

and packaging appropriate for shipment and storage.

Because it emphasizes the deliverable unit, “circuit card assembly” is often used when teams want the board to arrive as a verified, traceable building block rather than a “best effort” build.

People use these phrases interchangeably in emails, but they can mean different scope. Getting the scope right is the fastest way to avoid quote confusion.

A printed circuit board is the manufactured base: layers, copper, vias, solder mask, and surface finish. It has no components.

Circuit board assembly describes the process of placing and soldering components. It is sometimes used to describe a service, such as circuit board assembly services.

Printed board assembly and printed circuit assemblies usually refer to the result: the populated board.

Circuit card assembly typically implies a stronger “unit deliverable” mindset: inspection, test, and documentation expectations are clearer. It is very compatible with procurement workflows where traceability and acceptance criteria matter.

If your purchase order says “printed board assembly” but your team expects documented functional testing, you will often discover the mismatch too late. The simplest fix is to write the scope explicitly in a short “definition block” inside your request for quotation.

Many buyers ask: how much does a pcb cost? Others ask: how much does pcb assembly cost? They sound similar, but they are different budgets.

“How much does a printed circuit board cost?” is mainly about board fabrication (layers, materials, drill complexity, surface finish).

“How much does printed circuit board assembly cost?” includes fabrication plus components plus assembly labor plus setup plus inspection and testing plus yield and logistics.

This is why “price printed circuits” searches lead to confusing results. Some pages only quote the bare board. Some quote assembly labor only. Some quote a turnkey build that includes components. Without a cost structure, comparisons become unreliable.

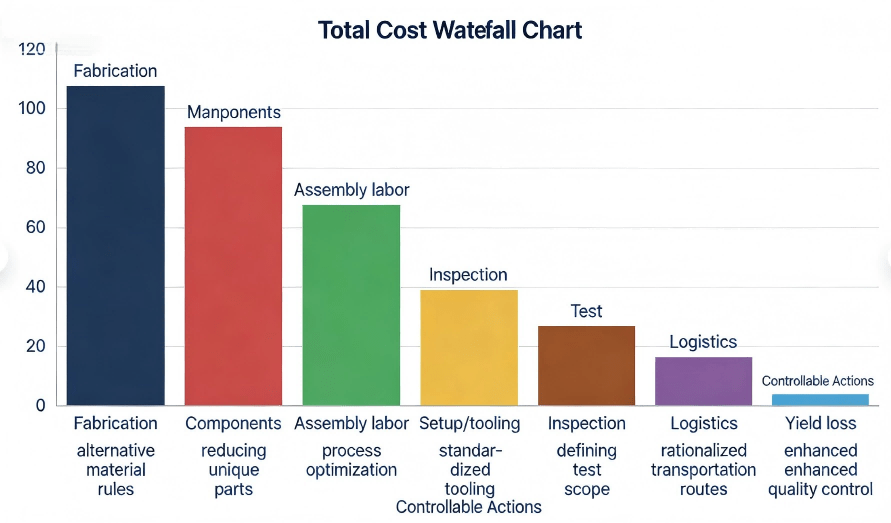

Hcjmpcba Total Cost Waterfall Chart (waterfall)

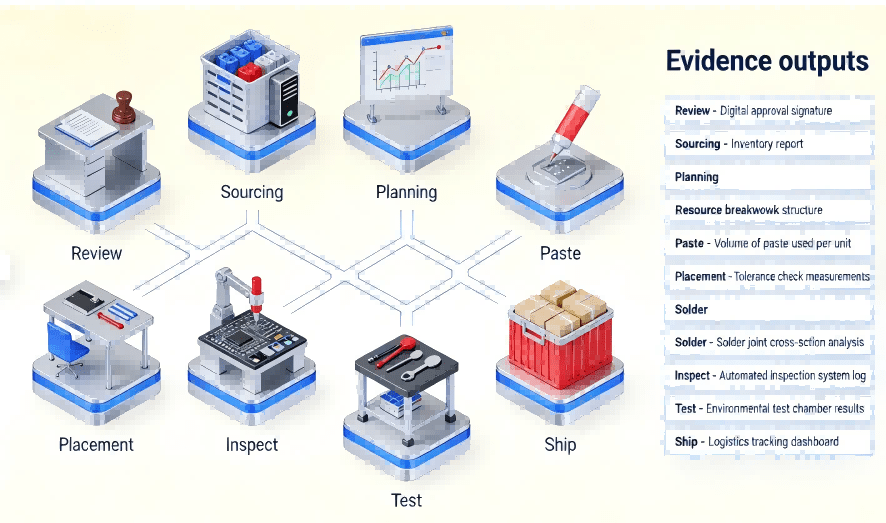

Below is a practical, procurement-friendly workflow. Each step includes what to provide, what happens, and what evidence to request so the result is measurable.

What to provide: design files (for example, manufacturing outputs and assembly drawings), bill of materials, and placement data.

What happens: the assembler reviews spacing, polarity markings, pad design, and test access.

What to request: a short written review identifying risks and clarifying questions.

This is where “pcb consulting” adds measurable value: problems found here cost minutes; problems found after assembly cost days.

What to provide: bill of materials with manufacturer part numbers and acceptable substitutes (if any).

What happens: lifecycle and availability are checked; alternatives are proposed if needed.

What to request: an approved vendor list or sourcing approach that avoids counterfeit risk and reduces delays.

A common reason that “low cost pcb manufacturing” becomes expensive is that parts go end-of-life, or suppliers swap parts without approval.

What happens: the assembly line plan is built: which side first, which parts are sensitive, and which steps require special handling (for example, moisture-sensitive components).

What to request: confirmation of any special constraints (baking, handling, packaging).

Solder paste printing can be a hidden cost driver in early builds because it often needs a stencil and setup time.

What to request: a line item for setup and any tooling, so you can amortize it correctly.

Surface mount assembly places components on the board automatically.

What to request: first article photos or a first article report that confirms orientation and critical parts before full production.

Some boards are purely surface mount. Others have connectors, relays, or power parts that require through-hole soldering.

What to request: a clear statement of which steps are automated and which are manual. Manual steps often explain quote differences.

Inspection can include visual checks, automated optical inspection (camera-based inspection), and X-ray inspection for hidden solder joints under certain packages.

What to request: inspection coverage (for example, full coverage or sampling) and the report format.

In-circuit testing checks connectivity and component presence/values using test points. Functional testing checks whether the board works in a real or simulated use mode.

What to request: pass/fail definition and measurement outputs for critical parameters.

For a true circuit card assembly deliverable, packaging and traceability matter.

What to request: serial or batch labels, packing photos if needed, and a summary of delivered documentation.

This workflow is valid whether you build simple pc boards or advanced assembly pcb designs. The difference is how strict the acceptance criteria become.

Assembly Flowchart

If you want assembly pricing to be predictable, avoid “single number” quotes. Use a cost formula that separates the drivers:

Total landed cost = board fabrication + components + assembly labor + setup and tooling + inspection and testing + logistics + yield loss (scrap and rework).

This is not just a finance tool. It is a risk tool. If a quote hides setup and test costs inside the unit price, you cannot compare it to another quote that lists them separately.

Cost ranges should be used carefully. Still, budgeting anchors are helpful at the start of a program.

Some suppliers publish assembly labor and indirect cost references in the range of $0.02–$0.05 per square inch. For small boards (for example, 2×2 to 4×4 inches), some guides mention per-board ranges like $5–$20 per board, depending on complexity.

These numbers can support early planning, but they can be misleading if you do not define scope. A “$10 board” might exclude:

components,

functional testing,

programming,

setup and tooling,

or yield assumptions.

If you need a single sentence to align teams: budget with ranges, but purchase with line items.

If you track only one section of this article, track this one. These are the drivers that explain most quote differences.

Components often dominate cost. A design with stable, widely available parts can be far cheaper than a design with one scarce part that forces broker sourcing or redesign.

Two boards can have the same total component count, but the board with more unique part numbers usually costs more to manage and build.

Fine-pitch parts, large ball-grid packages, and small leadless packages can require tighter process control and additional inspection steps.

Higher placement count increases machine time. Higher density increases risk and rework time.

Double-sided builds require more handling and often more risk control.

Manual work is usually the least predictable cost driver. It also varies widely by supplier capability.

Setup includes programming, first article validation, and often tooling such as stencils or test fixtures. Prototypes feel expensive because setup costs do not amortize.

Full coverage inspection costs more than sampling, but it can reduce rework and return risk. This is a business choice, not just a quality choice.

In-circuit testing and functional testing require planning and sometimes fixtures. They often raise cost and reduce risk at the same time.

Rush orders can force overtime, priority sourcing, and non-ideal process scheduling. Always ask what the expedite fee includes.

If you need a traceability report and controlled substitutions, the supplier must run a more disciplined system. That discipline is part of what you are buying.

Yield is the silent budget killer. A quote that looks low but produces frequent rework will cost more than a higher quote with a stable, high yield process.

This is why “pcb assembly price” cannot be a commodity number. It is a reflection of risk and process.

This section is written so procurement teams can use it as a checklist.

Fix: specify whether you want board fabrication, component procurement, assembly, and testing.

Fix: write an “approved substitute process” into the request for quotation.

Fix: ask for line items and define deliverables.

Fix: ask how rework is tracked and whether retest is included.

Fix: use a request for quotation checklist (provided later).

Fix: request tooling list early and specify fixture ownership.

Fix: ask what yield is assumed in the quote and what happens if yield drops.

Fix: confirm shipment terms and packaging requirements up front.

If you want a simple rule: any cost you do not define becomes a change order.

To reduce misunderstandings, define acceptance criteria in measurable terms. The table below is intentionally generic so it can be used across suppliers, and it avoids over-technical language.

| Category | What to Specify | Example Acceptance Criteria | What to Request as Evidence |

|---|---|---|---|

| Scope | Turnkey or customer-supplied components | Clearly stated | Itemized quote with scope statement |

| Workmanship | Acceptance level | Defined acceptance criteria for solder joints and placements | Final inspection record and criteria reference |

| Component sourcing | Authenticity and substitutes | Authorized sourcing + controlled substitutions | Sourcing summary + substitute approval log |

| Assembly method | Surface mount and through-hole steps | Steps confirmed | Process plan summary |

| Inspection | Coverage and method | Full coverage or sampling defined | Inspection summary report |

| X-ray inspection | When required | Required for packages with hidden joints (if present) | X-ray image set or summary |

| Electrical test | Definition of “pass” | Pass/fail criteria defined | Test log and measured values for key points |

| Programming | Firmware and configuration control | Version and checksum controlled (if applicable) | Programming log |

| Traceability | Serial and batch rules | Batch or serial mapping defined | Traceability report format |

| Packaging | Electrostatic discharge and moisture controls | Packaging requirements defined | Packaging checklist and photos if needed |

| Documentation | Deliverable pack | Defined list (inspection + test + traceability) | One bundled deliverable pack |

You can tune this table to your product category. For example, an automotive printed circuit board program may require deeper traceability than a consumer prototype. A camera circuit board may require stricter signal-integrity verification than a simple power board.

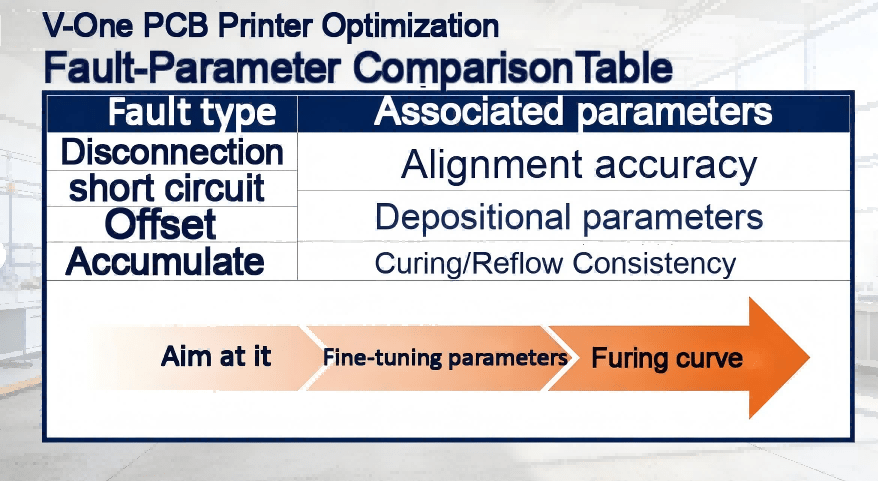

This section exists because teams increasingly ask about desk-scale prototyping tools and how they relate to cost. It also helps connect early learning with stable production.

A “pcb printer” can mean different things: some tools print conductive traces, some dispense paste, some support small prototype workflows. These tools can shorten iteration loops, but they do not automatically produce the same consistency as industrial PCB production.

Quick proof-of-concept traces for early testing

Rapid layout iteration before committing to fabrication

Early fit and connector placement checks

Training and low-risk experimentation

Designs that require tight impedance control

High component density builds

High reliability requirements

Repeatability at scale

To improve outcomes, the optimization approach should be systematic:

Design with the tool’s limits in mind

Early prototypes should use generous trace widths and clearances. Design rules that work for mass fabrication may be too aggressive for a desktop print.

Calibrate alignment first

Many failures that look like “material problems” are actually alignment problems. If pads are offset, the rest of tuning will not matter.

Control the deposition parameters with small changes

Change one parameter at a time, and record outcomes. Large adjustments make it hard to learn what caused improvement.

Stabilize curing or reflow steps

Inconsistent curing or reflow can create intermittent conductivity or weak solder joints.

Close the loop with simple tests

Use continuity checks and a short functional check immediately. Do not wait until the board is integrated into a full system.

Translate prototype learning into manufacturing files

Once the idea works, freeze the files that manufacturing needs: manufacturing outputs, bill of materials, placement data, assembly notes, and a test definition.

A second mention matters here because people search exactly for it: v-one pcb printer optimization is most valuable when it produces better design inputs for a production build, not when it tries to replace production.

V One Pcb Printer Optimization Fault Parameter Comparison Table

A technical buyer rarely needs promises. They need a process that produces repeatable output and evidence that the output meets an agreed definition.

HCJMPCBA can present circuit card assembly as an end-to-end workflow that aligns engineering, procurement, and quality:

Before quoting, the team checks whether the input package is complete. Missing placement files or unclear assembly notes are flagged early.

A short review clarifies:

packages that require special inspection,

components that pose sourcing risk,

and test access constraints.

Instead of chasing “low cost pcb manufacturing” headlines, the sourcing goal is stable supply. Where substitutes are allowed, the approval rule is documented.

Measurable checkpoints typically include:

first article confirmation for critical parts,

inspection records,

and defined rework tracking.

Testing is planned to match your product reality. If you only need power-on and basic functions, the test can be simple. If you need measured values, logs can be produced.

A procurement-friendly deliverable pack can include:

itemized build summary,

inspection and test evidence,

traceability mapping (batch or serial),

and packaging confirmation.

Important note for trust-proof writing:

Because certifications and equipment lists vary by factory line and project scope, the cleanest way to “prove trust” in a natural, non-promotional way is to show evidence examples: a sample inspection report, a sample test log, and a sample traceability format. These are more persuasive than long lists of claims.

If you want the fastest accurate quote, send a complete input package. This avoids the “back-and-forth” that adds days to quoting.

Provide:

Manufacturing outputs (for example, manufacturing files and stackup notes)

Bill of materials with manufacturer part numbers

Placement data (component locations and rotations)

Assembly drawing with polarity and special instructions

Quantity and expected ramp (prototype, pilot, production)

Target lead time and ship-to destination

Test definition: at minimum pass/fail; ideally measured values for key points

Programming requirements, if any

Packaging requirements (electrostatic discharge, moisture control, labeling)

This checklist is useful even if you are comparing multiple suppliers including names like sunstone circuits or marketplaces such as printed circuit board amazon listings. The goal is not to criticize channels. The goal is to compare apples to apples using the same scope and acceptance definition.

A circuit card assembly is a populated, soldered, inspected, and tested printed circuit board delivered as a functional electronic unit.

They overlap. Circuit board assembly often refers to the process, while circuit card assembly emphasizes the finished, verified deliverable unit.

It depends on scope. Costs include board fabrication, components, assembly labor, setup, inspection and testing, logistics, and yield loss. Budget ranges can help early planning, but a reliable quote requires complete files and a defined test plan.

Common reasons: different component sourcing assumptions, different inspection and test depth, different setup line items, different yield assumptions, and different definitions of what is included.

Standardize the bill of materials, reduce unique part numbers, choose manufacturable packages when possible, define substitutes properly, and align test depth to real risk.

Use it for fast learning and iteration; use an assembly supplier for repeatable results, controlled sourcing, inspection evidence, and scalable production.

A well-built circuit card assembly is not just solder and components. It is a deliverable unit with a clear definition of pass/fail, a defined scope, and evidence that supports acceptance.

Discover what a circuit diagram is and how to read or design a clear pcb schematic step-by-step. Und

Wondering what an HDMI RF Modulator is and how to pick one for your PCB/PCBA project? This guide bre

Discover the 7 powerful strategies to evaluate and select the best Automotive PCB Fabrication & Asse