1. Understanding SMT Manufacturing Basics

1.1 Defining SMT Manufacturing

SMT manufacturing (Surface Mount Technology) is a method of placing electronic components—known as Surface Mount Devices (SMDs)—directly onto the surface of a printed circuit board (PCB). Unlike through‑hole technology, which requires component leads to pass through drilled holes, SMT lets machines place parts on both sides of a board, enabling:

These advantages make SMT indispensable for today’s compact, high‑performance PCB assemblies (PCBAs).

1.2 Key Components in SMT

-

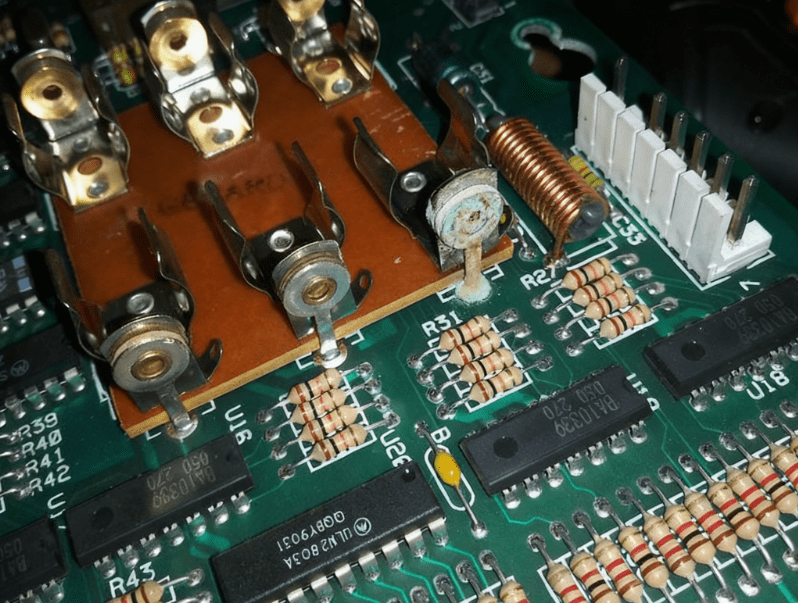

Resistors & Capacitors (0201, 01005 packages)

-

Integrated Circuits (QFP, BGA, CSP)

-

LEDs & RF Modules

Understanding smt vs smd:

SMT is the assembly process, while SMDs are the components placed during that process.

2. The SMT Production Process Unveiled

2.1 Pre‑production Preparation

-

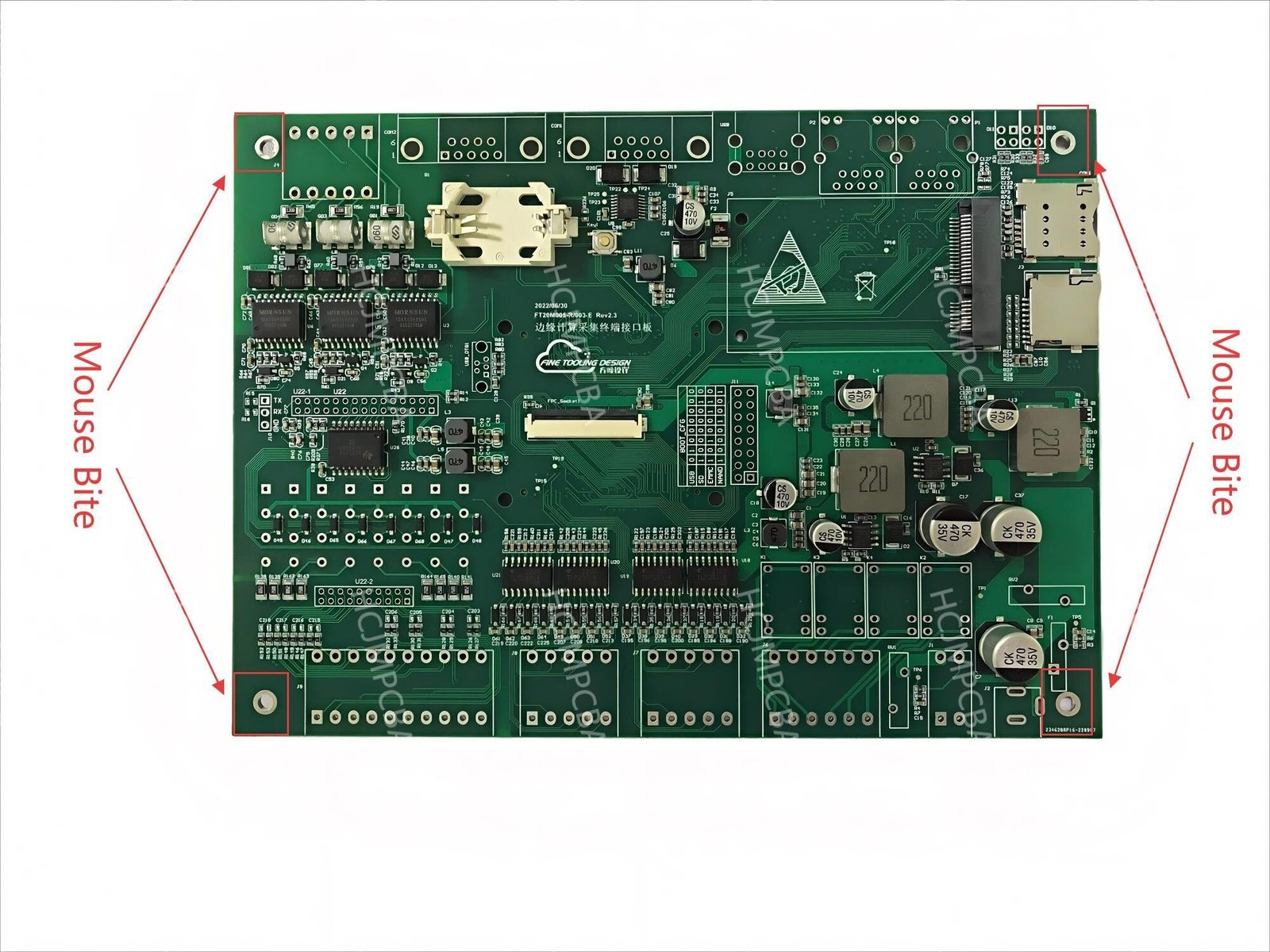

PCB Design for SMT

-

Pad geometry: Precise solder mask openings

-

Component placement: Minimize congestion, optimize signal paths

-

BOM & Gerber Files

This stage lays the foundation for a smooth smt pcb manufacturing process.

2.2 Step‑by‑Step SMT Process

1. Solder Paste Printing

2. Component Placement

3. Reflow Soldering

4. Inspection

-

AOI (Automated Optical Inspection) checks for missing, mis‑aligned, or bridged components.

-

X‑ray & SPI (Solder Paste Inspection) add further quality control in advanced facilities.

5. Rework (if needed)

This complete smt production process ensures each PCBA meets stringent reliability standards.

3. Benefits and Challenges of SMT Manufacturing

3.1 Advantages of SMT

-

Miniaturization: Supports 0201 and smaller packages for ultra‑compact designs.

-

Cost‑Effectiveness: Automated processes lower labor costs and waste.

-

High Throughput: Modern lines achieve 50,000+ placements per hour.

-

Reliability: Better mechanical performance under vibration and thermal cycling.

3.2 Overcoming SMT Challenges

-

Thermal Management: Precise oven profiling to protect heat‑sensitive parts.

-

Placement Accuracy: Regular calibration and vision‑guided alignment.

-

Solder Joint Quality: High‑grade solder and flux, combined with SPI feedback loops.

At HCJMPCBA, our ISO 13485‑certified protocols and in‑house R&D—plus dedicated AOI, X‑ray, and functional testing—address these challenges head‑on.

4. Selecting the Right SMT Manufacturing Supplier

4.1 Key Criteria for Supplier Evaluation

Experience and Expertise

-

Seek suppliers with 15+ years in smt manufacturing, proven across automotive, medical, and telecommunications markets.

Quality Certifications

-

ISO 9001 for quality management

-

ISO 13485 for medical device assembly

-

IPC‑A‑610 workmanship standards

Production Capacity & Flexibility

-

Ability to handle small‑batch prototypes and scale to mass production.

-

Support for high‑mix, low‑volume in North American & European markets.

Technology & Equipment

-

Modern pick‑and‑place lines, reflow ovens with nitrogen capability, AOI, X‑ray, and ICT.

Supply Chain & Logistics

-

Established parts network for J‑Lead, BGA, and 0201 sourcing

-

Fast, traceable shipping lanes to NA and EU destinations

4.2 Why HCJMPCBA Stands Out

-

One‑stop service: PCB design, prototyping, SMT/THT assembly, testing, plus inkjet printer integration.

-

Custom OEM support: From 0201 package tuning to specialized conformal coatings.

-

Proven success: Check our case studies for European medical and automotive ECU projects.

-

Global reach: Logistics partners across North America and Europe ensure on‑time delivery.

5. Conclusion and Next Steps

5.1 Recap of SMT Manufacturing

We’ve defined smt manufacturing, detailed its 7 critical steps—from paste printing to rework—and explored its benefits and challenges.

5.2 Engage with HCJMPCBA

Ready to partner with an ISO 9001 & ISO 13485‑certified leader in SMT manufacturing?