10 Must-Know Facts About HDMI RF Modulators: From Fundamentals to Choosing the Right One for Your PCBA Project

Table of Contents

ToggleIn today’s connected world, long-distance signal transmission is critical for various applications in smart homes, industrial control panels, and medical devices. An HDMI RF Modulator plays a pivotal role by converting HDMI’s digital audio/video signals into RF (radio frequency) signals. This conversion enables HDMI signals to travel over coaxial cables, a widely used infrastructure in legacy systems and large-scale setups.

For PCBA (Printed Circuit Board Assembly) teams, selecting the right HDMI RF Modulator and ensuring it integrates seamlessly into circuit boards is crucial for overall performance. With years of experience in PCBA assembly, HCJMPCBA has supported over 500 OEMs in optimizing HDMI RF modulator PCBA assemblies, helping reduce rework rates by 32%.

Long Distance Signal Transmission Via Hdmi Rf Modulator

An HDMI RF Modulator is an electronic device that converts high-speed HDMI signals (digital) into RF signals (analog or digital). The conversion allows HDMI content, such as 4K video or surround sound, to be transmitted over existing coaxial cable infrastructures. Unlike traditional HDMI extenders, which are limited to short distances (usually around 10 meters), HDMI RF modulators can transmit signals up to 300 meters with minimal loss when paired with quality PCBA.

The performance of an HDMI RF modulator relies on several key components, each playing a vital role in ensuring high-quality signal transmission:

HDMI Input Port: Receives digital signals from HDMI sources like set-top boxes and cameras. HCJMPCBA utilizes gold-plated connectors in PCBA to minimize corrosion and signal resistance.

Signal Conversion Chip: The heart of the modulator that converts HDMI signals into RF signals. HCJMPCBA uses state-of-the-art inspection methods like X-ray post-assembly to ensure there are no soldering defects that could impact the chip’s performance.

RF Output Module: This module transmits the converted RF signals through coaxial cables. HCJMPCBA tests impedance matching (50Ω/75Ω) to meet industry standards.

Power Management Unit: Supplies stable power to the modulator, usually in the form of 5V or 12V. HCJMPCBA’s DFM (Design for Manufacturability) analysis ensures optimal power trace layout to prevent overheating.

an HDMI RF Modulator showing its four main components, with specific components highlighted

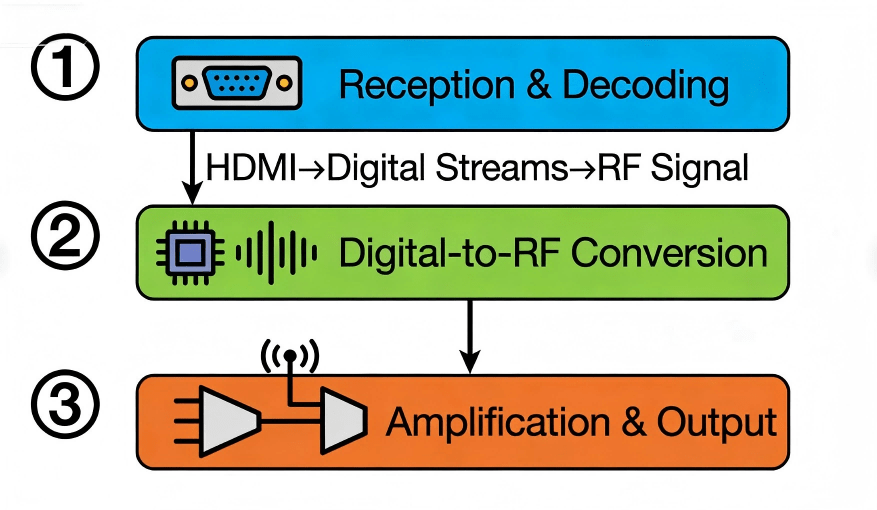

The modulator first receives uncompressed HDMI signals (up to 48Gbps for HDMI 2.1) through its input port. Inside the PCBA, a decoder chip processes the signal and separates it into individual audio and video streams. Proper synchronization at this stage is critical to prevent audio-visual lag. HCJMPCBA’s precise SMT (Surface Mount Technology) assembly ensures the decoder chip is placed with an accuracy of ±0.01mm, which is essential for maintaining signal timing.

The separated audio and video signals are fed into the conversion chip, which modulates them onto an RF carrier wave. This stage requires low-noise components to ensure minimal signal distortion. HCJMPCBA uses high-Tg PCBs (with a Tg ≥170℃) to reduce thermal noise, along with Automated Optical Inspection (AOI) to detect any faulty solder joints that could cause distortion.

Once the signals are modulated, they need to be amplified to overcome transmission loss over long coaxial cable distances. The power amplifier in the PCBA must balance gain (signal strength) and linearity (avoiding signal distortion). HCJMPCBA tests each modulator PCBA with a signal analyzer to ensure the output power is within ±0.5dB of the target, and the signal-to-noise ratio (SNR) is greater than or equal to 60dB, meeting industry standards.

Flowchart Of The 3 Stages Of Hdmi Rf Modulator Operation

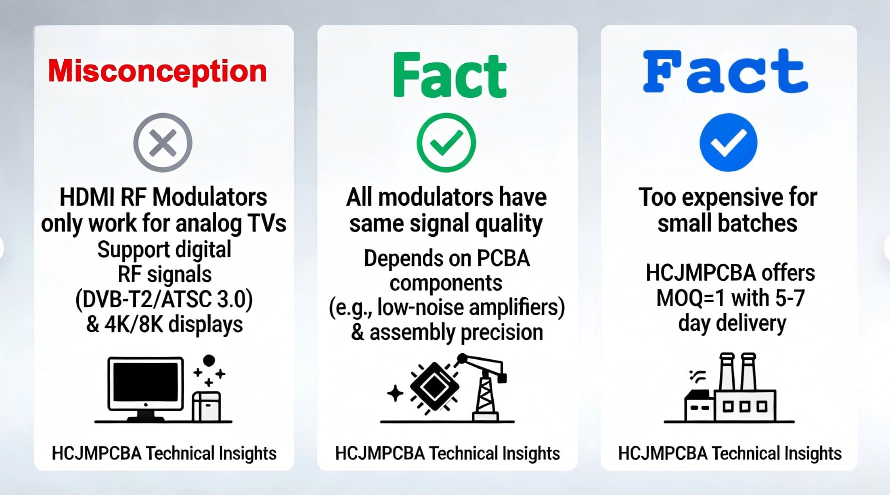

This is a misconception. Modern HDMI RF modulators support digital RF signals and are compatible with 4K and even 8K digital displays. HCJMPCBA has successfully assembled modulator PCBs for smart home systems that transmit 4K HDMI signals over 200 meters of coaxial cable with no loss in resolution.

Not true. The quality of the signal depends on the PCBA components used and the precision of the assembly process. HCJMPCBA ensures that modulator PCBs have a signal loss rate of less than 0.5%—far superior to the industry average of 2%, thanks to our rigorous multi-stage testing process (IQC → IPQC → FQC) and adherence to the IEC 61000-6-3 EMC standards.

This is another misconception. HCJMPCBA offers flexible small-batch assembly (MOQ = 1) for HDMI RF modulator PCBs. We also optimize costs through DFM analysis, such as reducing the number of components without compromising performance. A recent client managed to reduce their modulator PCBA costs by 18% after working with our engineering team.

Misconceptions About Hdmi Rf Modulators

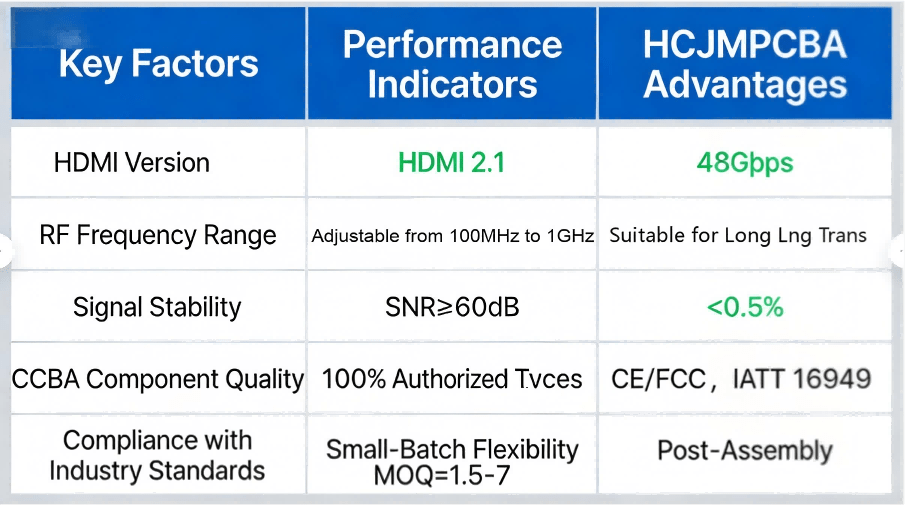

Ensure the modulator supports the HDMI version required for your project (e.g., HDMI 2.0 for 4K@60Hz or HDMI 2.1 for 8K@60Hz). HCJMPCBA verifies compatibility during DFM analysis, ensuring components are up-to-date to prevent costly rework.

Choose a modulator with an RF frequency range that fits your transmission needs. For short distances, 100–500MHz may be sufficient, while longer distances may require a range from 500MHz to 1GHz. HCJMPCBA’s testing lab can simulate real-world transmission environments to help you select the ideal frequency.

Look for modulators with a signal-to-noise ratio (SNR) greater than 60dB and a signal loss of less than 1%. HCJMPCBA performs 24-hour stability testing on each assembled modulator PCBA and provides a detailed report on SNR and loss data.

The quality of components, such as amplifiers and capacitors, is critical for ensuring durability and reliability. HCJMPCBA sources all components from authorized distributors and provides full traceability reports.

Ensure the modulator meets global standards like CE, FCC, and IEC 61000-6-3. HCJMPCBA’s modulator PCBs meet these standards and more, including IATF 16949 for automotive applications.

For R&D or prototype projects, choose a partner that supports small-batch orders (MOQ = 1). HCJMPCBA can deliver modulator PCBs within 5–7 days for small batches, along with free DFM feedback to optimize designs.

Look for manufacturers that provide post-assembly support, including testing reports and troubleshooting. HCJMPCBA offers a 12-month warranty on our modulator PCBs, with engineers available for technical queries within 24 hours.

Hdmi Version Compatibility

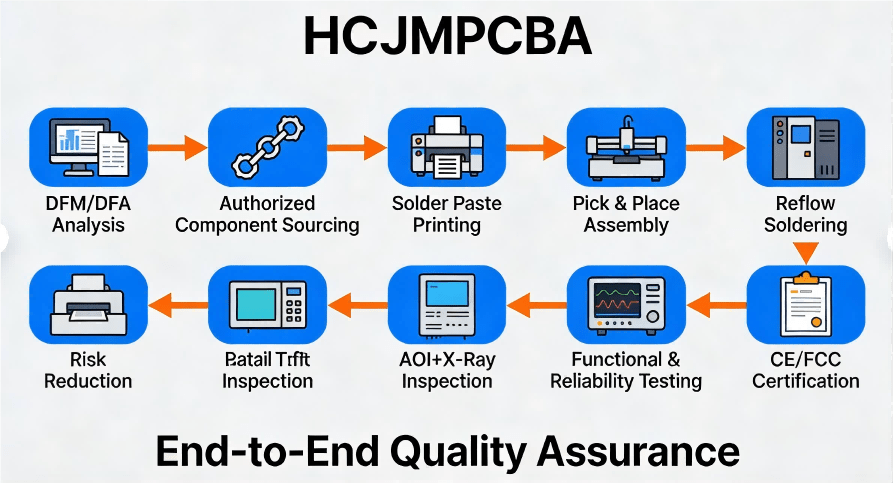

HCJMPCBA offers a comprehensive process, from DFM analysis to precision assembly and comprehensive testing. Our team optimizes designs for minimal interference, uses only authorized components, and ensures PCB assembly accuracy of ±0.005mm. Our process includes full post-assembly testing to verify performance.

HCJMPCBA is ISO 9001, IATF 16949, ISO 13485 certified, and our modulator PCBs meet CE, FCC, and RoHS standards. For example, a European smart home OEM reduced their modulator PCBA rework rate by 32% after switching to HCJMPCBA.

HCJMPCBA minimizes procurement risks with component traceability, pre-assembly DFM checks, third-party testing reports, and flexible payment terms. New clients can benefit from our 50% advance, 50% on delivery payment structure.

Process Flow Chart Of Hcjmpcba’s Pcba Assembly Process

Q1: Can an HDMI RF Modulator transmit multiple HDMI signals at once?

Yes, multi-port HDMI RF modulators (e.g., 4-in-1) can handle multiple HDMI sources. HCJMPCBA assembles PCBs for multi-port modulators with proper isolation between ports to prevent signal crosstalk.

Q2: What’s the maximum transmission distance for an HDMI RF Modulator?

Typically, the maximum range is 100–300 meters, depending on the quality of the coaxial cable and RF frequency. HCJMPCBA can test modulator performance at different distances to confirm real-world transmission range.

Q3: Do I need a separate power supply for the HDMI RF Modulator?

Most HDMI RF modulators require 5V/12V DC power. HCJMPCBA can integrate the power management module directly into the PCBA, eliminating the need for an external power adapter.

Q4: How long does HCJMPCBA take to assemble HDMI RF Modulator PCBs?

For small batches (1–100 units), we deliver in 5–7 days; for larger batches (1000+ units), delivery takes 10–14 days. Rush orders can be accommodated in 3 days for critical projects.

An HDMI RF Modulator is essential for long-distance HDMI signal transmission, but its performance depends entirely on PCBA quality. HCJMPCBA ensures that all modulator PCBs meet the highest standards, offering minimal signal loss (<0.5%), high SNR (≥60dB), and compliance with international certifications. Whether you are an OEM engineer designing a smart home system or a procurement manager sourcing components for industrial control panels, HCJMPCBA minimizes procurement risks and optimizes costs.

Guangzhou Huachuang Precision Technology ensures high PCBA reliability through advanced SMT and BGA

An LED PCB is a specialized printed circuit board designed for LED applications, delivering electric

A wiring diagramt (also known as an electrical schematic) shows how electrical components and connec