High-Reliability PCB Warpage Prevention: Ensuring Performance in Medical, AI & Industrial Electronics

PCB warpage is a critical issue in medical devices, AI hardware, and industrial automation, where di

Small Water Pumps: 12 Expert Steps to Make a Reliable Mini Water Pump (2025 Updated Guide)

Table of Contents

ToggleIn today’s technology landscape, small water pumps, also called miniature water pumps or little water pumps, are compact fluid transfer devices designed to move water or other liquids within tight spaces with low power consumption and high efficiency. These pumps are essential across many systems — from decorative fountains and aquariums to portable sinks, solar irrigation systems, and medical fluid circulation modules.

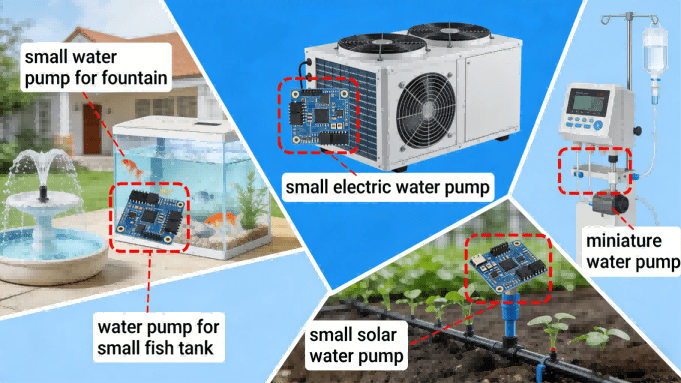

Engineers and procurement teams often search for terms like small water pump for fountain, small electric water pump, small submersible water pump, or water pump for small fish tank when selecting components that must integrate with control electronics (e.g., speed control, sensor feedback, and safety shutdown). Understanding what a small water pump is and how it works — including its electronic control logic — is crucial for PCB/PCBA OEM engineers and buyers to make reliable design decisions.

What this guide covers:

✔ Definition and working principles of small water pumps

✔ Types and applications (submersible, solar, electric, portable)

✔ Step-by-step guide to building a mini water pump

✔ Common problems and expert solutions

✔ HCJMPCBA’s custom PCBA capabilities that boost performance and reduce risk

Panoramic View Of Small Water Pumps Application Scenarios Hcjmpcba

A small water pump is a compact liquid transfer device that converts electrical energy into mechanical energy to move water or light liquids. It typically operates at low voltages (e.g., DC 3–24V) and is designed for small flow and moderate head applications such as fountains, aquariums, or small appliances.

These pumps are often called miniature water pumps or even mini water fountain pumps when used in decorative or portable water features. Their compact size makes them ideal for portable systems and space-constrained designs.

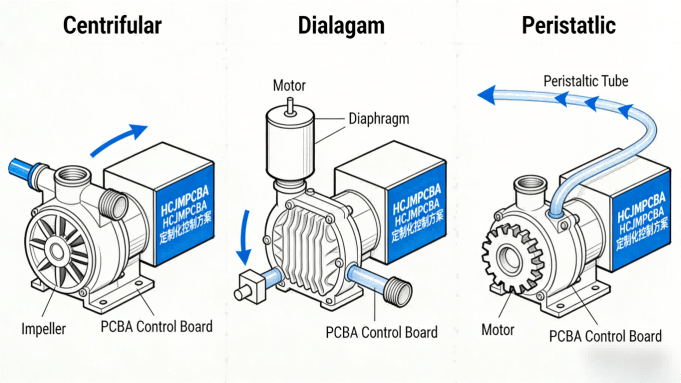

At their core, small water pumps rely on a simple but effective mechanism: the conversion of rotary motion from an electric motor into fluid movement using an impeller or diaphragm system. Here’s a simplified breakdown:

Electric Motor Activation: Power (DC or AC) drives the pump’s motor.

Impeller/Diaphragm Motion: The rotating impeller (or oscillating diaphragm) creates a pressure difference that draws fluid into the inlet and forces it out the outlet.

Fluid Movement: Water flows through the pump body and is discharged into hoses or outlets connected to the system.

In small pump designs, the motor often directly drives the impeller, with the pump’s printed circuit board assembly (PCBA) controlling motor speed, monitoring pressure, and executing safety shutdowns to protect against dry running or overload.

| Specification | Small Submersible Water Pump | Small Solar Water Pump | Small Electric Water Pump |

|---|---|---|---|

| Voltage Range | 3–12V DC | 12–24V DC (solar) | 110–240V AC/DC |

| Flow Rate | ~2–7 L/min | ~2–43 L/min | ~4.5–10 L/min |

| Max Head | ~1.5–3 m | ~2–42 m | ~3–25 m |

| Typical Use | Aquarium / Fish Tank | Remote irrigation | Portable sink / fountain |

Note: Specifications vary widely by model and application needs — choose based on required head, flow, power availability, and environmental conditions.

Schematic Diagram Of The Working Principle Of Mini Water Pump Hcjmpcba

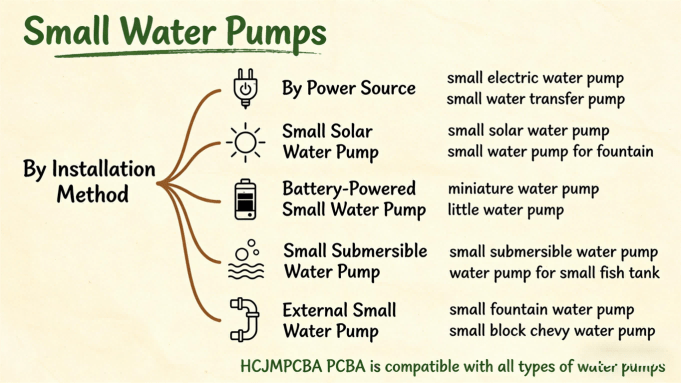

These pumps use electrical power (AC/DC) for stable and continuous operation. They are commonly used in household appliances, fountains, and small fluid circulation systems.

Systems like small water pump with hose configurations require careful control electronics to manage flow and prevent backflow, which is where custom PCBA design (like HCJMPCBA’s control boards) significantly improves reliability.

Powered by solar panels, these pumps are ideal for off-grid irrigation, garden fountains, and remote water circulation. Solar pump performance often depends on sunlight and may include battery backup for extended operation.

These are highly portable and suitable for emergency water transfer, DIY projects, or portable sinks where mains power isn’t available.

Designed to operate underwater — suitable for fish tanks, aquariums, and decorative fountains. Submersible units are often sealed to prevent water ingress and mechanically isolated from electronics.

Used in tabletop fountains, portable sinks, or automotive applications such as cooling systems. These pumps sit outside the fluid and typically connect through hoses.

Classification Tree Diagram Of Mini Water Pump Types Hcjmpcba

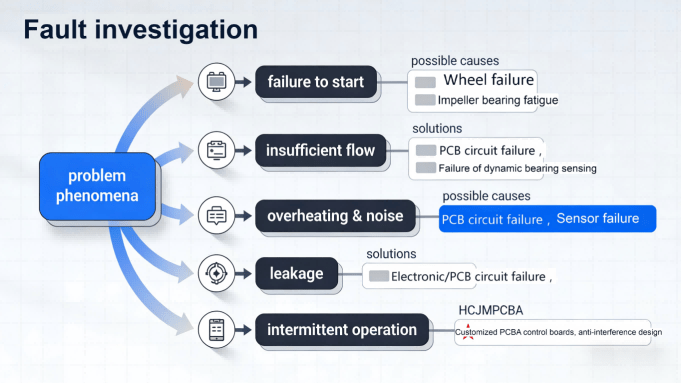

Common causes: voltage instability, blockages, or PCB control errors.

Solution: Verify supply voltage with a multimeter and perform PCB diagnostic to check for shorts or failed components.

Causes: clogged hoses, worn impeller, speed control issues on the PCB.

Solution: Clean hoses, inspect impeller, and calibrate control board parameters.

Causes: poor ventilation, bearing wear, poor thermal management.

Solution: Improve heat dissipation and consider thermal-rated PCBA assemblies.

Causes: damage to seals or insufficient waterproof design.

Solution: Use IP67-rated components and waterproof PCBA designs.

Mini Water Pump Common Troubleshooting Flowchart Hcjmpcba

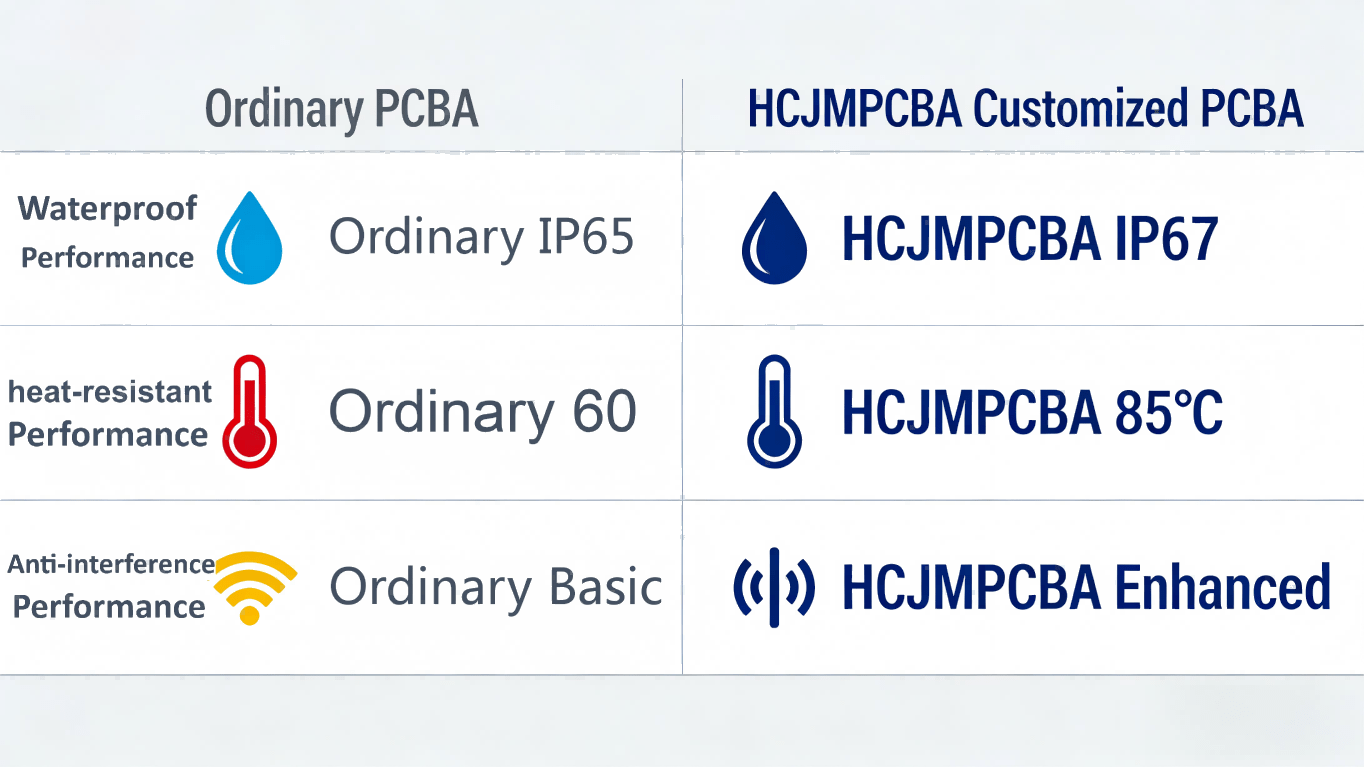

Mini Water Pump Comparison Chart Of Pcba Protection Hcjmpcba

For engineers and hobbyists alike, understanding how to construct a basic small water pump can deepen your understanding of fluid dynamics and PCBA integration.

12V DC micro motor (or suitable voltage motor)

Pump housing (3D printed or molded)

Plastic impeller

Custom control PCBA (for motor speed control)

Seals, hoses, fasteners

Power supply (battery/adapter)

Design the Pump Housing: Model in CAD and print or fabricate.

Assemble Motor & Impeller: Mount securely and ensure smooth rotation.

Design & Solder Control PCB: Include motor driver, PWM control, and protection features.

Integrate PCB with Pump Mechanics: Ensure sealing and routing of wires.

Connect Power & Test: Verify flow rate and leak performance.

Calibrate: Adjust motor speed using PCBA controls for desired performance.

HCJMPCBA provides tailored PCB assembly design and production services for all small water pump variants — from submersible pumps and solar-powered units to portable fountain and aquarium pumps.

Key capabilities include:

✔ Customized PCB layout for diverse pump types

✔ High-precision SMT/DIP assembly with IPC-A-610D quality standards

✔ IP67/IP68 waterproof PCBA for submersible designs

✔ Fast prototyping and scalable production capacity

Understanding what a small water pump is, how it works, and how to build or select the right one is essential to designing reliable fluid systems. With precise PCBA design, robust assembly processes, and expert troubleshooting from HCJMPCBA, you can significantly improve performance and reduce procurement and operational risk.

Learn more about PCBA services, please contact Guangzhou Huachuang Precision Technology.

PCB warpage is a critical issue in medical devices, AI hardware, and industrial automation, where di

Discover pcb board washer methods tailored for HCJMPCBA’s SMT‑built assemblies—from manual bru

Discover what a blank PCB and parts are—you'll learn about blank PCB board, bare printed circuit b