Full Turnkey – High Quality – Quick Turn

PCB Assembly Services

Full Turn-Key PCB Assembly

Partial Turn-Key Flexibility

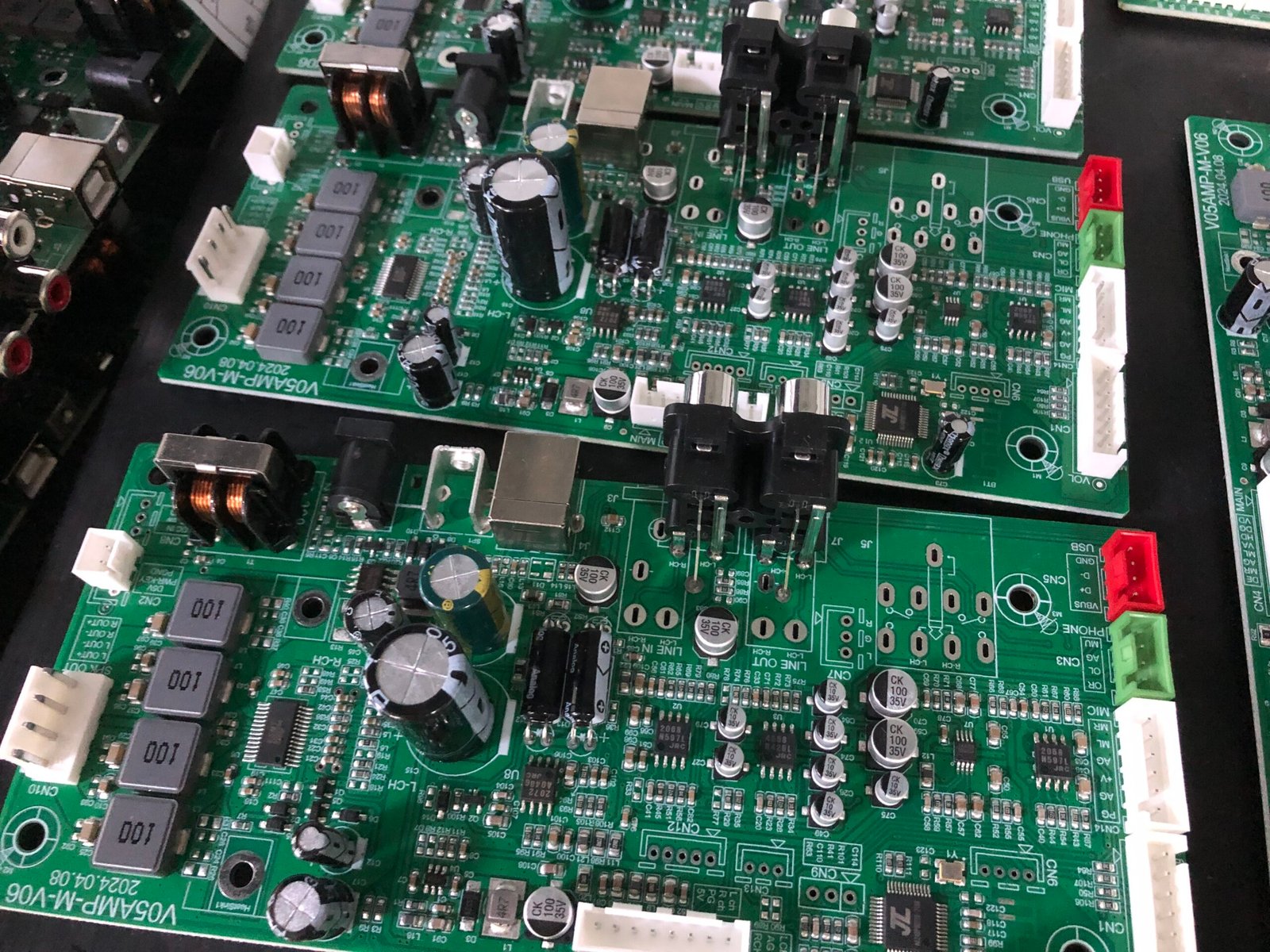

Printed Circuit Board Assembly Services

- Full turnkey, partial turnkey, and consignment PCB assembly solutions

- Rapid prototyping to large-scale production PCB assembly

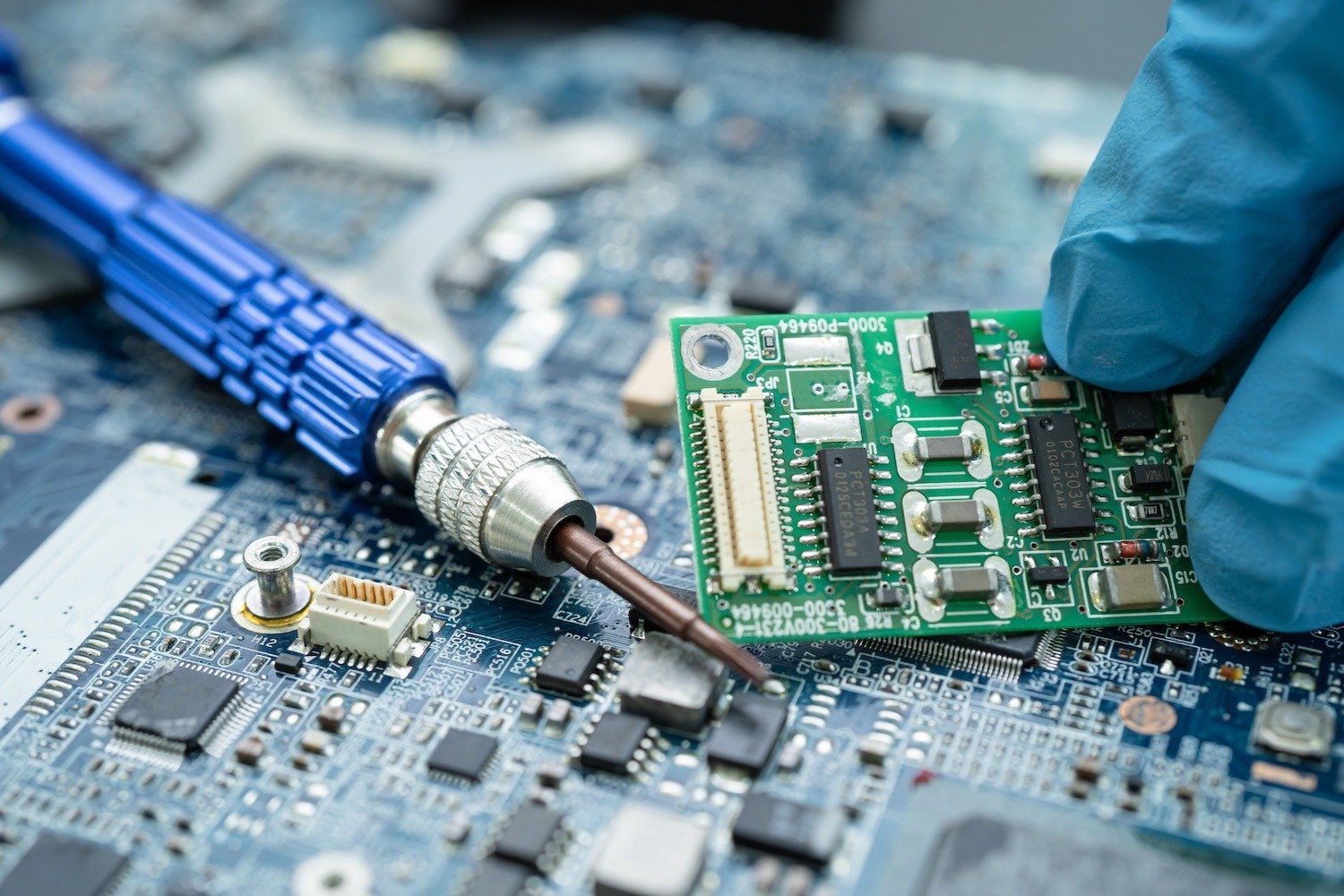

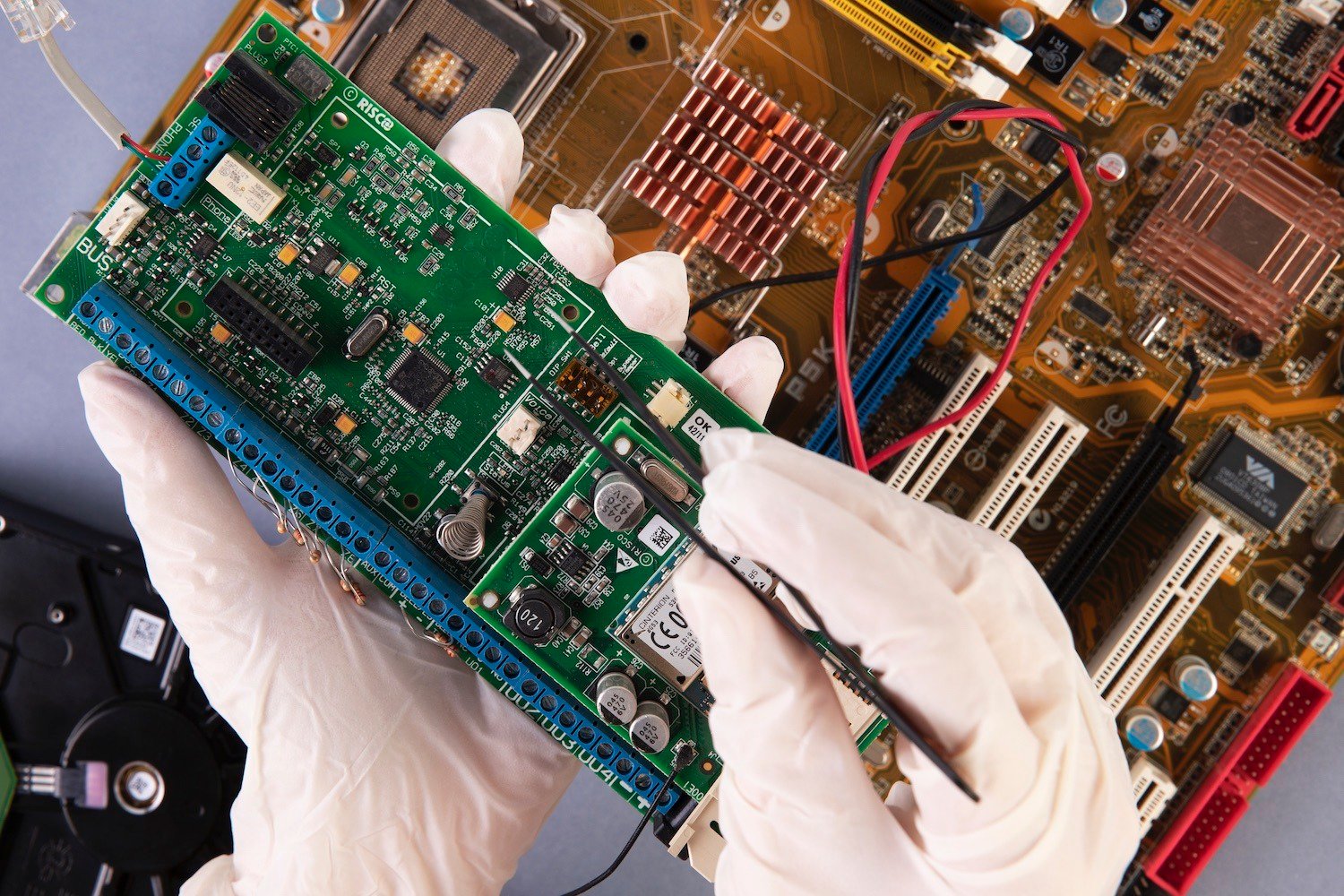

- SMT Assembly supporting 0201 components, BGA, QFN, and fine-pitch technologies

- Through-Hole Technology (THT) for connector, relay, and mixed-technology board assembly

- RoHS and non-RoHS compliant assembly options

- Functional testing, burn-in testing, and quality inspection

- Material sourcing & component procurement from authorized distributors

- Order tracking, shipping, and logistics management

- Custom cable harness assemblies (multiconductor cables, ribbon cables, wire harnesses)

Our one-stop PCB assembly solutions integrate cutting-edge technology and industry expertise to support your electronic projects—from prototype to mass production. Here’s how we deliver seamless value across every stage:

basic service

basic service Core PCB Fundamental Capabilities

Foundational PCB Services

Assembly Expertise

Assembly Expertise Professional Assembly Solutions

Assembly Expertise

Value-Added Capabilities

Value-Added Capabilities In-Depth Technical Empowerment

Value-Added Capabilities

PCBA Lead Time

- Submit Gerber files, BOM (Bill of Materials), and project requirements to our team

- Our engineering team provides a detailed quote within 24 hours

- Confirm the quotation and proceed with purchase order & payment arrangement

- We arrange bare PCB manufacturing and component procurement

- Incoming material inspection and internal DFM (Design for Manufacturability) review

- For production orders, assembly (SMT/THT) is completed in 2–7 days based on order volume

- Comprehensive quality inspection (AOI, X-ray, manual visual check, functional testing)

- Global shipping via air/sea with delivery in as fast as 2 business days worldwide

- Gather customer feedback and provide post-delivery support

- Complete the order with full documentation and traceability

| Order Quantity | Standard Lead Time | Quick Turn Lead Time |

|---|---|---|

| QTY ≤ 50 | 5 Working Days | 1 Working Day |

| 50 < QTY < 100 | 8 Working Days | 3 Working Days |

| 100 < QTY < 1,000 | 10 Working Days | 5 Working Days |

| 1,000 < QTY < 10,000 | 15 Working Days | 7 Working Days |

| Capability | Standard |

|---|---|

| Certifications | ISO 9001:2015, ISO 13485 |

| Assembly Types | SMT, Through-Hole, Mixed Technology; Single/Double-Sided SMT/PTH |

| Component Sizes | Passive: down to 01005; Fine-pitch: down to 8 mils pitch |

| PCB Layers | Up to 32 layers (HDI, rigid, rigid-flex supported) |

| Lead Time | Prototyping: 3–7 days; Mass Production: 10–25+ days (per schedule) |

| Inspection & Testing | AOI, X-ray, ICT, Functional Testing, Aging Tests |

| Solder Type | Leaded, Lead-free (RoHS compliant) |

| File Formats | Gerber (RS-274X/274D), Eagle, DXF, DWG, Pick-and-Place Files |

| Rework Capability | BGA removal/replacement, SMT IR rework, Through-Hole rework stations |

SMT Engineering & Technical

- All Posts

- Blog

Guangzhou Huachuang Precision Technology Co.,Ltd.employs advanced X-RAY detection to provide non-destructive,high-precision inspection for electronic products,identifying hidden defects and ensuring reliability.

The article provides an in-depth look at the advanced equipment,rigorous processes,skilled workforce,and lean management practices of Guangzhou Huachuang Precision Technology…

The DIP and SMT technologies of Guangzhou Huachuang Precision Technology Co., Ltd., highlighting their features and the company's excellence in…