PCB Manufacturing

Advanced PCB manufacturing services, specializing in high-precision, complex designs, and diverse materials, serving industries such as industrial control, medical devices, smart manufacturing, AI, and autonomous driving.

About Us

Guangzhou Huachuang Precision (HCJMPCBA) is a trusted one-stop provider of high-precision PCB/PCBA services for global clients in medical devices, industrial control, and consumer electronics. Backed by ISO 9001 & ISO 13485 certifications, we deliver end-to-end support from design optimization to mass production.

Key Advantages

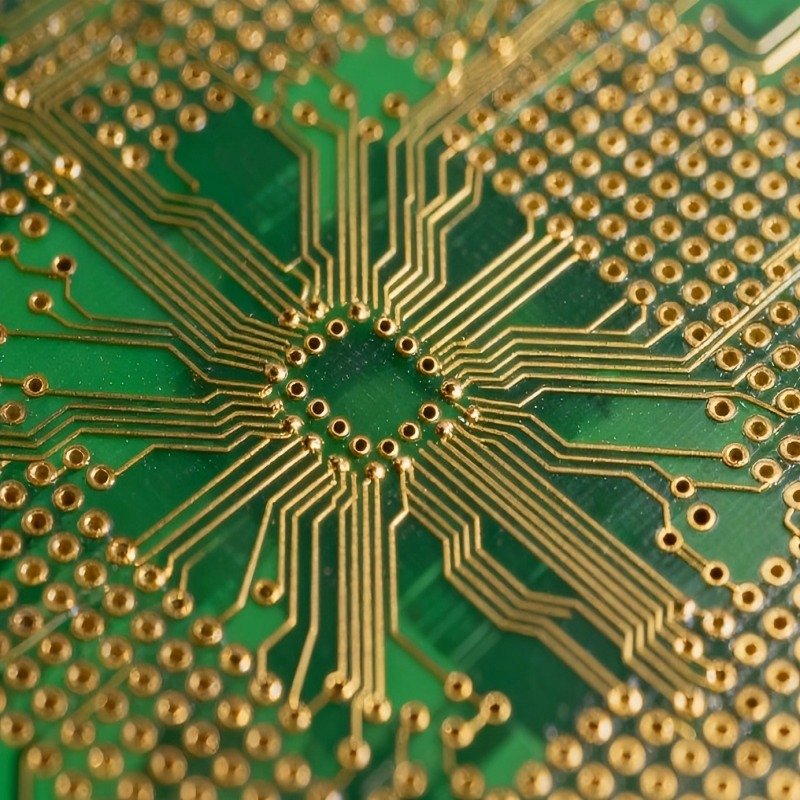

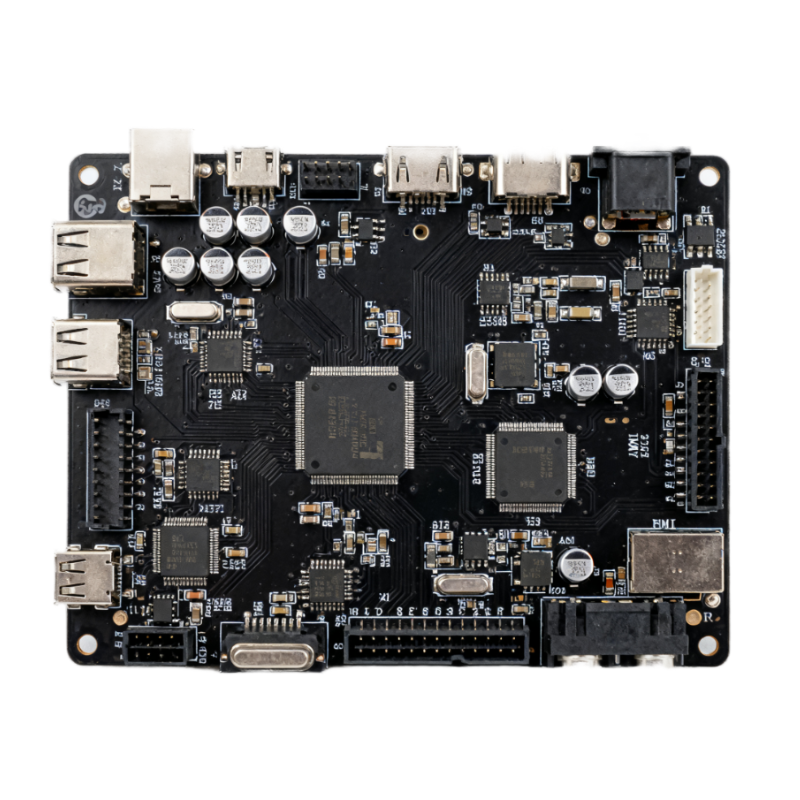

- PCB Manufacturing

2-8 layer PCBs (prototyping & mass production) with 0201/BGA/QFN support. 7-10 day fast delivery, plus AOI/ICT dual QC for ≥99% yield.

- One-Stop PCBA

Turnkey solutions: SMT, DIP, IC programming, functional testing. Full support from Gerber analysis to finished assembly.

Key Advantages

- Proven Experience: 100,000+ order batches delivered; customized solutions for diverse industries.

- Tech Assurance: Advanced SMT/X-ray equipment; regular calibration for stable complex processes.

- Value-Added Services: Centralized component sourcing, real-time progress updates, after-sales support.

PCB Types We Served

Copper Core Pcb

Rogers Pcb

Heavy Copper Pcb

High Tg Pcb

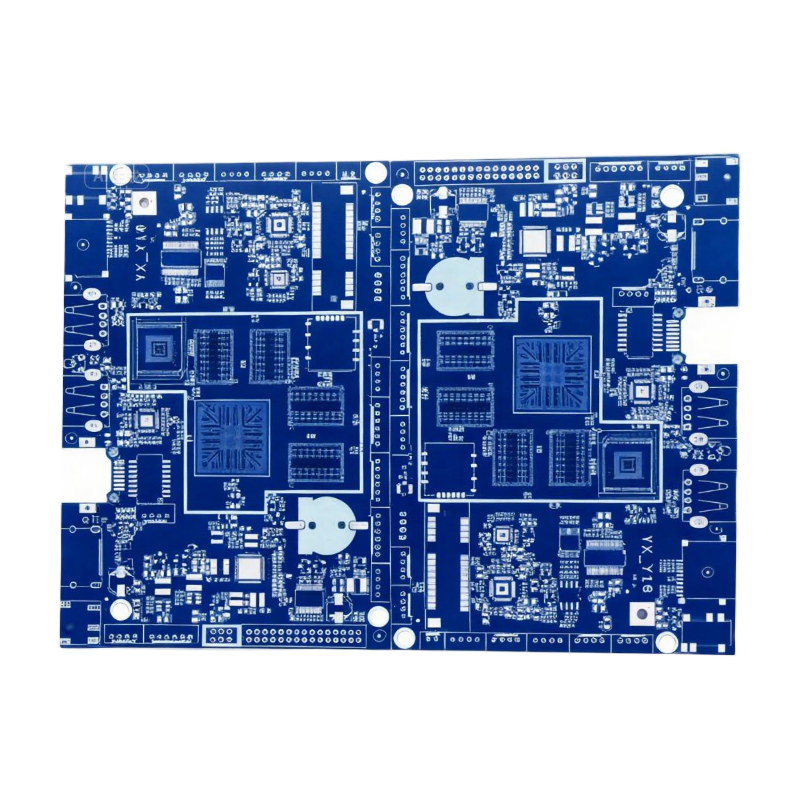

Latest PCB Projects

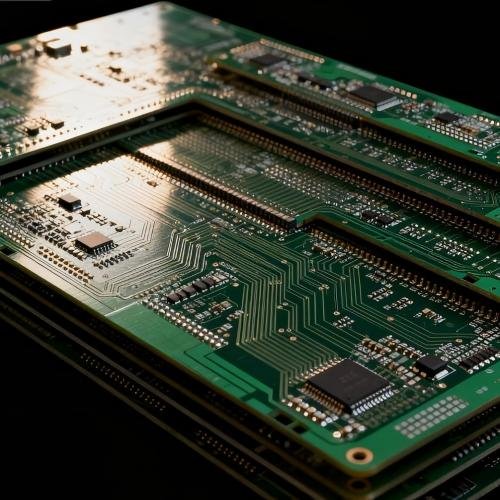

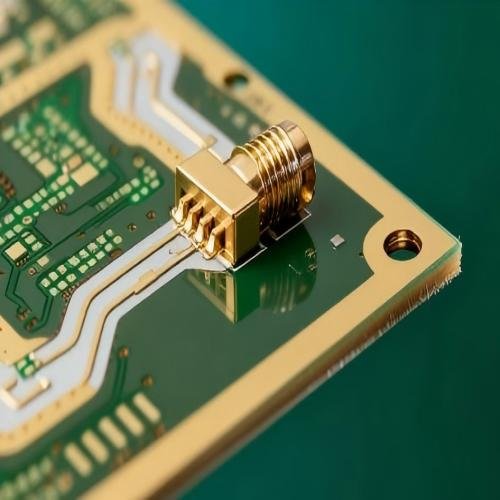

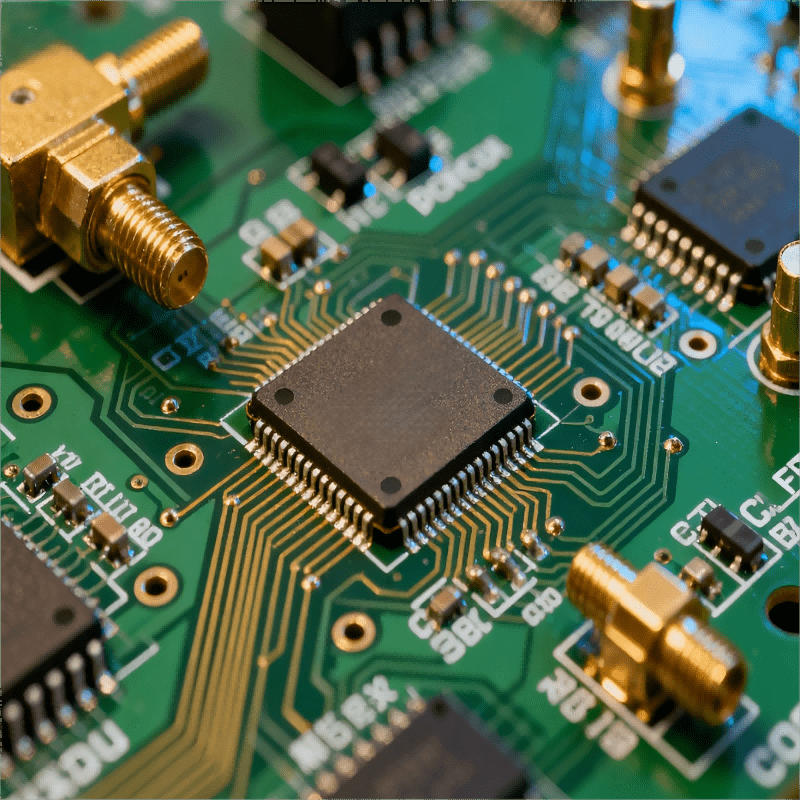

High - Density Interconnect (HDI) PCB

Offers high – density wiring for compact electronic devices.

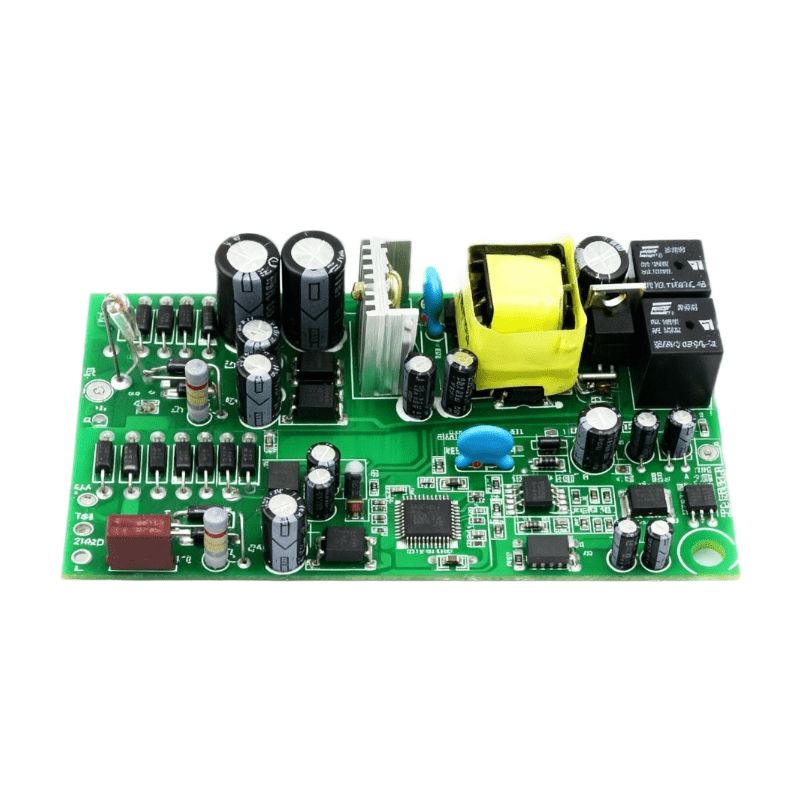

Power Supply PCB

Optimizes power conversion and distribution for various electronic products.

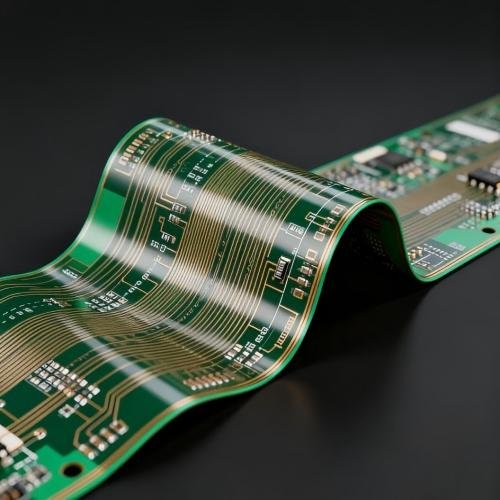

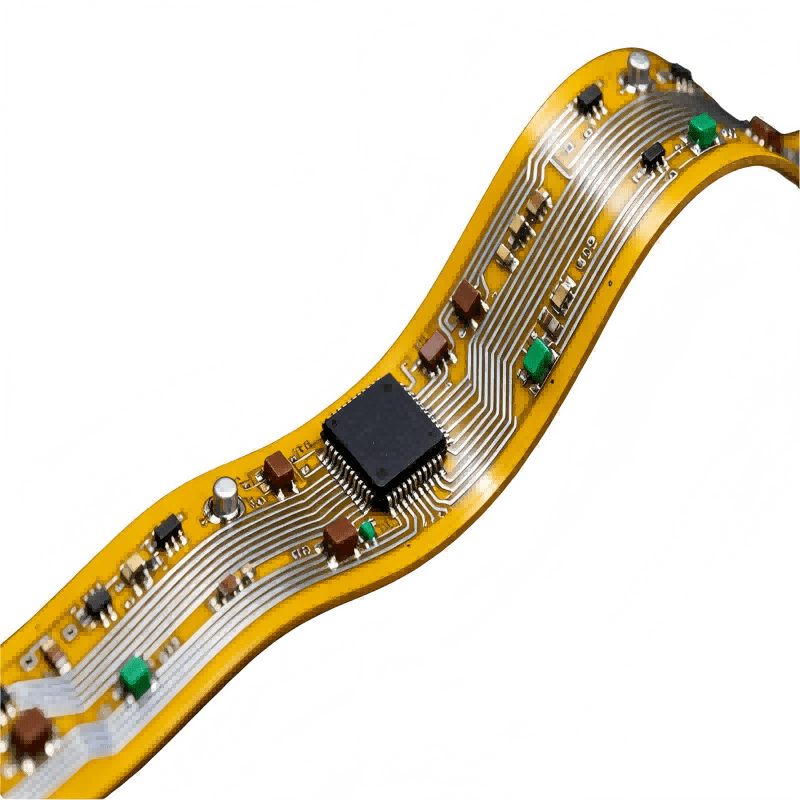

Provides bendable circuitry for space – saving and movable electronic assemblies.

High Frequency PCB

Suitable for high – frequency signal transmission with special dielectric constant and loss factor substrate.

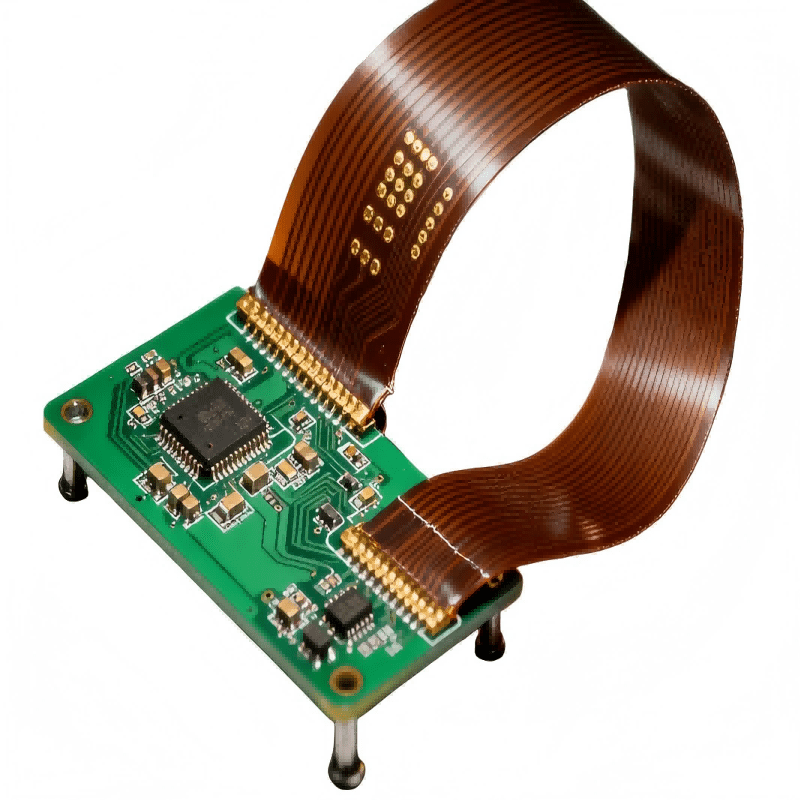

Rigid - Flex PCB

Combined by rigid and flexible substrates for complex electronic assemblies.

Metal - Core PCB

Uses metal or metal composite as substrate for excellent heat dissipation.

5G Communication PCB

Enables high – speed signal transmission for 5G base stations and devices.

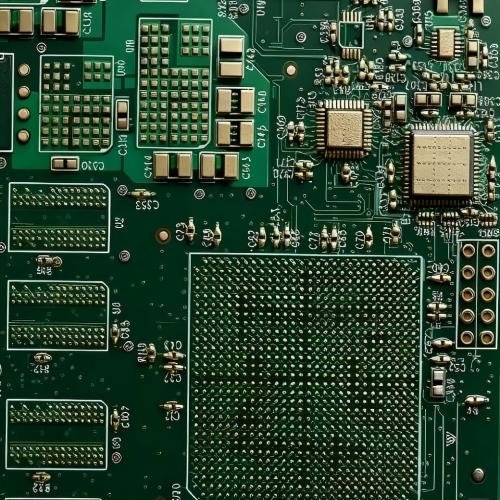

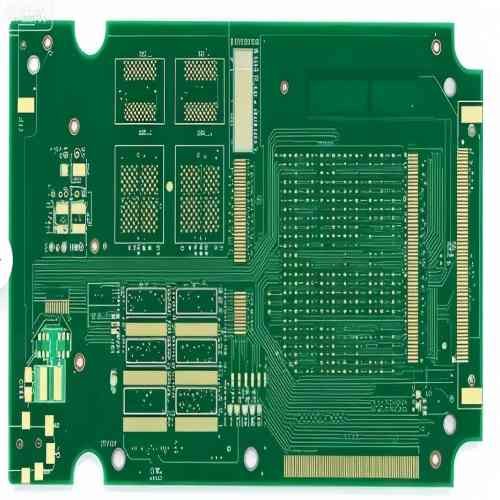

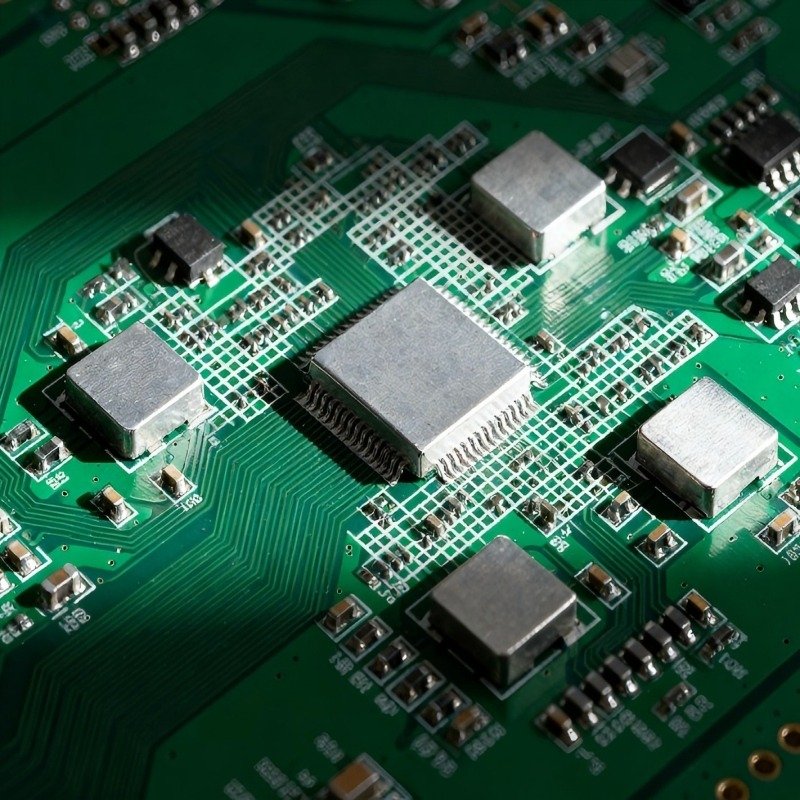

Industrial Control PCB

Ensures stable performance in industrial automation control systems.

Automotive Electronics PCB

Designed for high – reliability applications in automotive electronic systems.

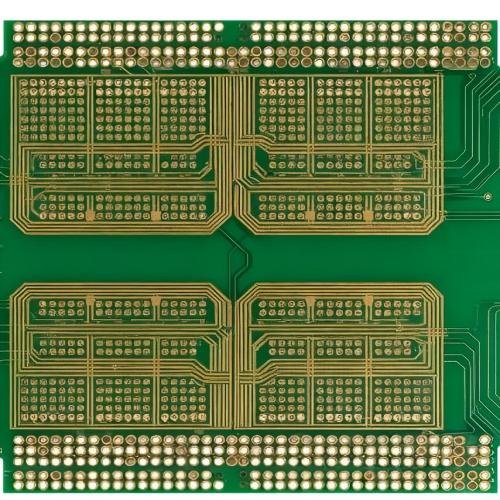

| Feature | Capability |

|---|---|

| PCB Type | Rigid PCB (CEM, FR4), Flexible PCB, Rigid-Flex PCB, MCPCB (Aluminum Base), Ceramic PCB, RF PCB, etc. |

| Layer Count | 1 – 32 Layers |

| Order Quantity | 1 Piece – 10,000,000 Pieces |

| Lead Time | 2 Days – 5 Weeks (Expedited Service Optional) |

| Base Materials | FR4 (Standard Tg 150°C, High Tg 170°C/180°C), Halogen-Free FR4, High-Tg Halogen-Free FR4 |

| Board Size Range | Min: 6x6mm | Max: 600x700mm |

| Board Size Tolerance | ±0.1mm – ±0.3mm |

| Board Thickness | 0.4mm – 3.2mm |

| Copper Weight | 0.5oz – 6.0oz |

| Min Trace/Spacing | 3mil/3mil |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Surface Finish | HASL, Lead-Free HASL, ENIG, ENEPIG, Immersion Silver, Immersion Tin, OSP |

| Min Drilling Hole | 6mil (Conventional) / 4mil (Laser Drill) |

| Impedance Tolerance | ±5% – ±10% |

| SMD Pitch | 0.2mm (8mil) |

| Special Techniques | Gold Fingers, Blind/Buried Vias, Peelable Solder Mask, Edge Plating, Carbon Mask, Via-in-Pad, Electrical Testing, etc. |

HCJMPCBA Factory Environment