12 Essential Steps in the PCB Manufacturing Process: A Practical, Risk-Reducing Guide for Industrial Buyers

Learn the complete pcb manufacturing process in a clear, step-by-step way—from design review (DFM)

What is a PCB? A Complete Guide to Printed Circuit Boards and How Circuit Boards Work

Table of Contents

ToggleA succinct answer suitable for featured snippets

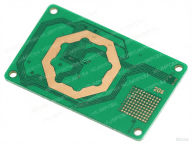

PCB board = printed circuit board: a flat non-conductive board (e.g., fiberglass or epoxy) with conductive copper traces for electrical connection

Alternate terms: printed circuit boards, electronic circuit board, printed circuit board

Context: essential in nearly all electronic products

Definition: PCB stands for Printed Circuit Board

It mechanically supports and electrically connects components (ICs, resistors, capacitors) via copper traces

Used as a bridge between engineer intent and device functionality in modern electronics

Core function: copper traces form pathways for electricity, akin to roads routing signals

Construction: insulating substrate (often FR-4) + etched copper layers, sometimes laminated multi-layer for complexity

The board enables structured signal flow, controlled routing, and component integration

Key parts: traces, pads, vias (through-hole, blind, buried)

Electronics: resistors, capacitors, transistors, ICs – all mounted via SMD or through-hole

Example analogy from a reddit user:“A circuit board itself simply provides connections between electrical components. It’s a little bit like running wires between a bunch of other parts.”

Layer breakdown: substrate (FR-4), copper layers, solder mask, silkscreen

FR-4: flame-resistant fiberglass epoxy — common non-conductive base

Solder mask protects traces; silkscreen aids assembly labeling

Essential parts: integrated circuits, connectors, sensors, and other active/passive elements

These components interface via pads on the PCB

Classified by structure and material:

Single-sided, double-sided, multi-layer

Rigid, flex, rigid-flex offering varying mechanical properties and design flexibility

High-density interconnect (HDI), aluminum-backed, metal-core, ceramic, and more NCAB GroupCadence PCB

These serve high performance, compact, or rugged applications such as aerospace, automotive, and 5G

Design to fabrication process:

AD design and schematic capture

Layer etching, drilling, plating, lamination, solder mask, silkscreen application

QA: continuity checks, AOI, ICT, X-ray testing

SMT advantages: fast, high component density, double-sided, better RF and EMC performance

Through-hole: robust mechanical strength, still used for heavy components

Testing methods ensure reliability and performance on each PCBA

Ubiquitous use in consumer electronics: smartphones, computers, appliances

Industrial, automotive (including EV systems), aerospace, medical, telecommunications, AI & automation

High-speed, high-layer PCBs for 5G, high-reliability boards for aerospace & defense

HCJMPCBA can empower these industries with high-precision assembly and custom solutions

What is a PCB board in simple terms?

A flat board that mechanically supports and electrically connects components via copper traces

What is a PCB used for?

Routing signals, enabling component integration, and forming functional electronic devices

Difference between a circuit board and a PCB?

Essentially none—both refer to the same thing (“circuit board” is generic, “PCB” is formal)

How long do PCBs last?

Lifespan depends on materials, environment, and use, commonly lasting many years if well-designed

What materials are used in PCBs?

Commonly FR-4 substrate, copper conductors, solder mask, silkscreen, and sometimes polyimide or metal cores

What does PCB mean in electronics?

Acronym: Printed Circuit Board

In summary, a pcb board—or printed circuit board—is the foundational platform for electronic devices, providing electrical pathways, mechanical support, and interconnectivity. Understanding what is a printed circuit board and how circuit boards work helps cross-industry professionals make informed design and procurement decisions. From single-sided to multi-layer, rigid-flex to high-density, PCBs come in myriad forms tailored to diverse applications.

Learn the complete pcb manufacturing process in a clear, step-by-step way—from design review (DFM)

A flame sensor is a critical safety device that detects flame presence to prevent gas leaks and expl

Discharging capacitors is a critical safety and quality control step in electronics and PCBA work. T