Exploring PCBA Technology: The Core of Electronic Manufacturing at Guangzhou Huachuang Precision Technology Co., Ltd.

This article provides an in-depth exploration of PCBA technology, its evolution, key processes, chal

What Is an Unmanned Combat Aerial Vehicle (UCAV)? A Reliability-First Electronics & PCBA Guide

Table of Contents

ToggleAn unmanned combat aerial vehicle (UCAV) is an unmanned aircraft designed for combat missions. Unlike general-purpose UAVs, UCAV programs typically require higher reliability, stricter documentation, and tighter electromagnetic and environmental performance. In practice, UCAV capability is enabled by flight-critical electronics—power distribution, navigation, secure communications, compute, and payload interfaces—where PCB assembly quality, traceability, inspection, and test coverage directly affect mission readiness and lifecycle cost.

An unmanned combat aerial vehicle (UCAV), sometimes called a combat drone or UCAV drone, is a specialized class of UAV / UAS (unmanned aerial systems) designed not only for surveillance and intelligence, but also for conducting armed strikes and combat missions. Unlike conventional reconnaissance drones, UCAVs carry munitions—missiles, bombs, guided weapons—and operate under various levels of autonomy or remote human control.

In modern warfare and defense strategy, UCAVs are becoming increasingly central. They reduce risk to human pilots, enable new mission profiles, lower operational costs, and complement manned aircraft in loyal wingman roles or swarm formations. However, deploying UCAVs imposes strict demands on subsystems—avionics, navigation, communications, stealth, control systems, and of course high-reliability electronics including PCB / PCBA.

This article unpacks:

What constitutes a UCAV (vs generic UAV)

Evolution and market trends of UCAVs

Core subsystems and technological requirements

Operational use cases

Key challenges, risks, and technical barriers

The crucial role of PCBA / electronics in UCAV platforms

Future directions and emergent trends

FAQs to clarify common questions

A summary of key takeaways

By the end, you’ll better understand how UCAVs are built, why they matter, and where electronics manufacturing (especially high-reliability PCBA) plays a pivotal role.

A UCAV is a type of unmanned aerial vehicle (UAV) specifically optimized for combat operations. The key differences from generic UAVs include:

Weaponization: UCAVs are equipped with offensive payloads such as missiles, bombs, or guided munitions, mounted on hardpoints or internally.

Combat mission roles: Beyond surveillance or reconnaissance, UCAVs may perform air-to-ground strikes, suppression of enemy air defenses (SEAD), and even air-to-air engagements in advanced designs.

Higher autonomy and control complexity: UCAVs often require real-time decision-making systems, autonomous target identification, tighter integration with command & control (C2) systems.

Risk profile: Because they are unmanned, UCAVs can be deployed deeper into contested zones or riskier environments than manned aircraft.

In most definitions, UCAVs remain a subclass of UAV / UAS. As Britannica describes, UAVs are aircraft guided autonomously or by remote control, carrying sensors or ordnance.The Wikipedia entry for unmanned combat aerial vehicle also clarifies: “UCAVs … carry aircraft ordnance … under varying levels of autonomy.”

Thus, while all UCAVs are UAVs, not all UAVs are UCAVs.

The concept of unmanned combat drones has been explored for decades. One of the early technology demonstrators was the X-45 UCAV, developed under the U.S. J-UCAS program (Joint Unmanned Combat Air Systems). The X-45A flew multiple test missions to validate autonomous control, weapons carriage, and integration concepts.

Later, platforms such as the X-47B by Northrop Grumman served as a more advanced prototype for carrier-based UCAV operations.

As electronics, autonomy, sensor technology, and materials advanced, UCAVs have gained traction in modern defense planning.

Several factors push UCAV adoption:

Reduced pilot risk: removing the human from direct exposure to hostile airspace.

Cost advantages: UCAVs can have lower lifecycle cost than manned fighters or strike aircraft.

Improved autonomy, AI, and sensor tech: enabling more independent operations.

Greater demand for persistent coverage, stand-off strike, and swarm tactics.

The unmanned combat aerial vehicle market is projected to grow significantly. Defense budgets globally emphasize military drones, air force drones, and autonomous warfare. Some defense firms and startups are actively developing next-gen UCAVs (e.g., Helsinki’s “Europa” drone unveiled recently). Reuters

In current reporting, many of the “best military drones” are UCAV or strike-capable UAVs (e.g., MQ-9 Reaper, Bayraktar TB2) forming benchmark platforms.

Thus, the UCAV sector is no longer speculative—it’s a core strategic investment domain for advanced militaries.

To operate effectively in contested airspace, a UCAV integrates multiple sophisticated subsystems. Below, we break them down, and highlight where PCBA / electronics are mission-critical.

Airframe design: aerodynamic form, internal weapon bays, materials (composites, radar-absorbing materials)

Propulsion: jet or turbofan engines, possibly hybrid or electric systems; needs high reliability and thermal management

Stealth and signature control: minimized radar cross-section (RCS), infrared signature suppression, acoustic damping

These subsystems demand tight integration with sensors and avionics and require tolerances for vibration, shock, temperature gradients.

Flight control systems (FCS): autopilot cores, inertial measurement units (IMUs), gyros, accelerometers, control actuators

Navigation & guidance: GNSS, terrain reference (TRN), optical / lidar / radar guidance

Sensors suite: EO/IR cameras, synthetic aperture radar (SAR), lidar, electronic warfare sensors

Data processing / AI modules: real-time signal processing, target detection, tracking

These submodules rely heavily on multi-layer PCBs / PCBA to integrate high-speed digital, RF, analog, and power circuits.

Weapon control modules: arming, release, missile guidance interface

Targeting & fire control modules

Secure communication links: encrypted data links, satellite comms, link redundancy

Sensor fusion & decision logic: onboard software correlates sensor data

Latency, reliability, shielding, and redundancy are critical. One failure in the electronics chain can disable the combat mission.

Here’s where your domain (PCB / PCBA) becomes strategic. UCAVs must manage:

Power distribution: from generator or battery to subsystems

Voltage regulation, battery management systems (BMS)

High-reliability switching, redundancy circuits, fault tolerance

Thermal management (heat sinking, conduction, cooling)

EMI / signal integrity, isolation, shielding, ruggedization

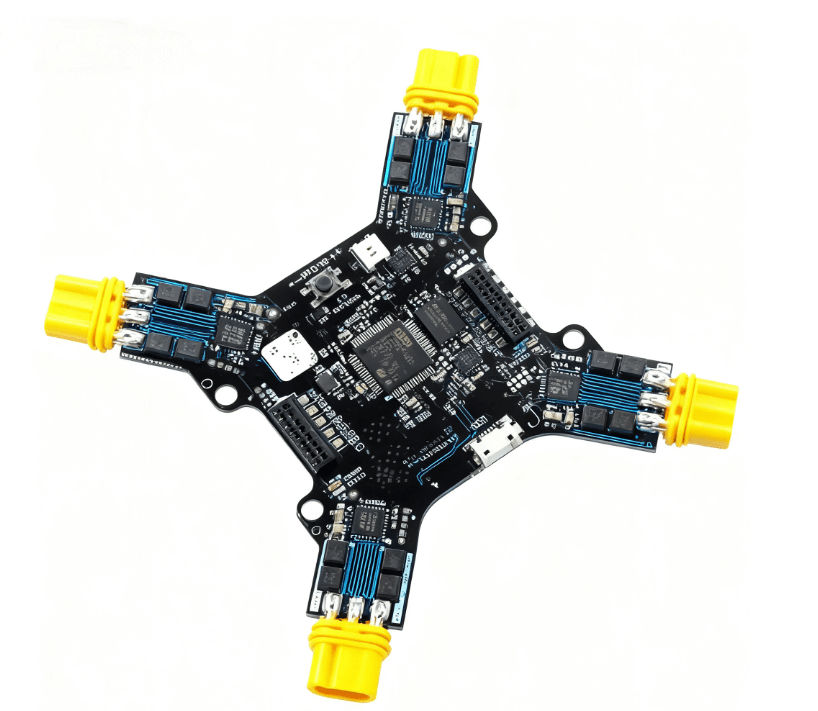

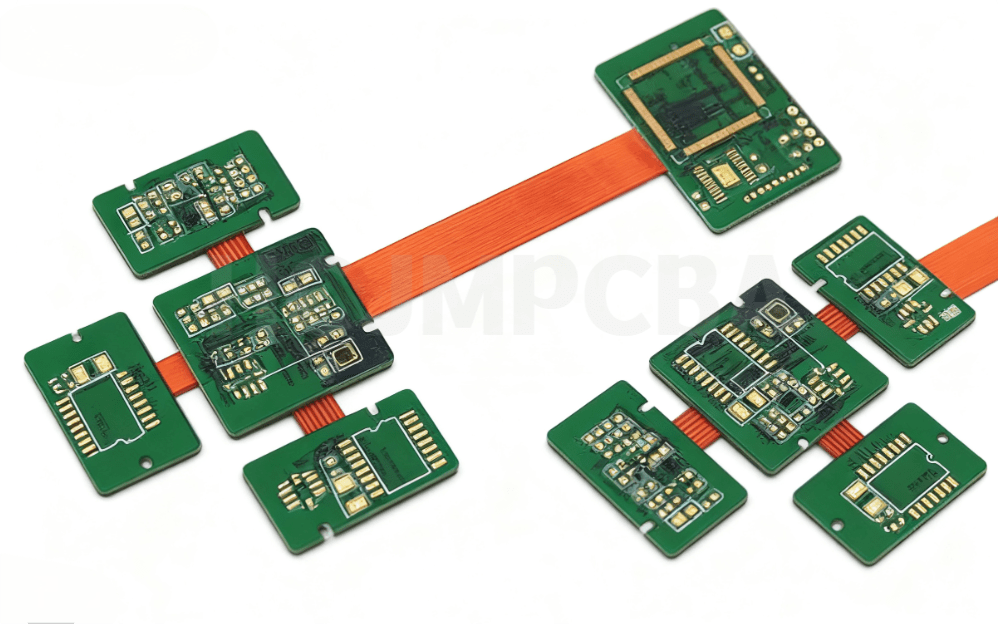

In fact, UCAV electronics demand miniaturization, lightweight, multi-layer high-density interconnects (HDI), impedance control, buried / blind vias, and material selection tolerant to temperature, shock, and vibration. For drones / UAVs, PCB / PCBA design techniques must ensure reliability and performance under flight stresses.

For example, drone PCBA manufacturing requires, as noted, multi-layer HDI boards with laser-drilled vias, stringent impedance control, fine trace/space, and selective surface finishes to ensure signal quality and reliability.

Thus, the electronics / PCBA subsystem is a core enabler of UCAV capability.

Understanding where UCAVs add value helps clarify why their complexity is justified.

While ISR is a domain of general UAVs, UCAVs combine ISR with strike capability. A UCAV may loiter over a target, collect high-resolution sensor data, and deliver weapons—all in one mission profile.

UCAVs can engage ground or maritime targets with guided munitions. They may also serve in SEAD / suppression of enemy air defenses, neutralizing threats before manned aircraft enter contested zones.

One emerging paradigm is pairing UCAVs with manned aircraft: UCAVs act as “wingmen,” performing reconnaissance, suppressing threats, taking on risk tasks while the manned aircraft perform higher-level missions. The U.S. Air Force recently flew Kratos XQ-58 Valkyrie drones in exercises integrated with F-16 / F-15 jets in this “loyal wingman” role.

Multiple UCAVs acting in concert (swarm tactics) may overwhelm defenses, distribute attack profile, or provide redundancy. Advanced AI coordination is key in swarm architectures.

Because UCAVs can be more expendable than manned aircraft, they may penetrate denied zones or maintain presence over hostile airspace for extended periods. Their endurance and autonomy become critical.

Some of the most recognized UCAV / combat UAV platforms:

MQ-9 Reaper: a long-endurance, strike-capable drone widely used by U.S. and allies.

Bayraktar TB2: a Turkish medium-altitude long-endurance (MALE) UAV used in multiple conflict theaters.

X-47B UCAV demonstrator from Northrop Grumman.

Kratos XQ-58 Valkyrie: stealthy tactical UCAV design used in loyal wingman tests.

Europa (Helsing): a European AI-powered UCAV concept recently unveiled.

These platforms illustrate the diversity of size, mission, and autonomy in the UCAV domain.

This section ties directly to your PCBA / PCB manufacturing domain. In UCAV systems, electronics are not an afterthought—they are enablers of performance, survivability, and capability.

UCAV electronics require compact, high-density boards with minimal footprint and weight.

Multi-layer HDI boards, microvias, blind / buried vias, and impedance-controlled traces are standard.

Selective surface finishes and shielding layers are necessary.

As noted in drone PCBA manufacturing, achieving stringent trace/space (e.g., 3/3 mil), OSP or ENEPIG finishes, buried vias, and fine-pitch components is common practice.

Heat sinks, thermal vias, conduction planes must be built into PCB/PCBA.

Use of vibration-damping materials and mechanical isolation for sensitive circuits.

Shock qualification: circuits must survive G-levels of vibration and sudden maneuvers.

High-frequency communication, radar, and sensor signals demand excellent isolation and filtering.

Ground planes, separated analog/digital zones, shield cans, and EMI suppression networks are essential.

Power electronics need isolation barriers (e.g. DC-DC converters, galvanic isolation) and well-planned layout.

Redundant circuits: dual-masters, fallback controllers.

Built-in test (BIT), fault monitoring, telemetry feedback for onboard diagnostics.

Conformal coating, rugged components, temperature range components.

High-reliability production standards (IPC Class 3 or aerospace-grade)

Strict process control, ESD protection, quality assurance, and traceability

Environmental testing: thermal cycling, humidity, vibration, salt spray if maritime

Companies in the PCB / aerospace domain often advertise capabilities in “aerospace / UAV PCBA, EMI control, thermal management, miniaturization, high-speed signal integrity” to service drone / UCAV customers.

Thus, PCB / PCBA firms that can meet these stringent standards will be in a strategic position to support UCAV platform development.

Cooperative behaviors among multiple UCAVs (e.g. swarm tactics) will grow. Autonomous coordination, sensor sharing, distributed decision-making, and dynamic re-tasking are emergent capabilities.

AI-driven mission planning, target recognition, adaptive routing, and autonomous decision loops will reduce human oversight demands—but safety, accountability, and trust in AI remain challenges.

Designing UCAVs with modular payload bays (laser, EW modules, sensors) lets customers reconfigure vehicles for mission needs. Standardized interfaces and modular electronics help this flexibility.

New composites, additive manufacturing, improved batteries or hybrid systems can reduce weight and extend endurance—relieving some constraints on electronics.

Advancements in stealth, radar absorbent materials, and adaptive camouflage will push new electronics layout strategies. Countermeasures like electronic warfare (EW), spoofing, anti-UAV systems also drive resilience in UCAV design.

As UCAVs proliferate, international treaties, export control regimes, and airspace integration policies will evolve. Clear frameworks for unmanned combat aerial vehicle market regulation will shape adoption.

Below are frequently asked questions about unmanned combat aerial vehicles and their technical, operational, and development challenges.

Q: What’s the difference between a UCAV and a UAV?

A: A UCAV is a UAV designed specifically for combat / strike missions—it carries weapons and has the control and autonomy systems to execute attacks. In contrast, many UAVs are focused purely on surveillance, reconnaissance, mapping, or sensor roles without weapon systems.

Q: Can UCAVs operate fully autonomously without human oversight?

A: Some UCAV designs aim for high autonomy, but most deployed systems today retain human-in-the-loop control for weapon release decisions, mission changes, and critical engagement choices for safety and accountability.

Q: What challenges do electronics / PCBA subsystems face in UCAVs?

A: Electronics must be miniaturized, rugged, thermally managed, EMI-controlled, and highly reliable. Vibration, shock, thermal stress, and strict isolation are constant design constraints.

Q: Are there export controls or regulations on UCAV technology?

A: Yes. Many UCAV components, algorithms, and subsystems fall under military or defense exports control regimes (e.g. ITAR in the U.S.). Compliance with international treaties, certifications, and government oversight is mandatory.

Q: Which UCAV platforms exist today or under development?

A: Platforms include MQ-9 Reaper, Bayraktar TB2, X-47B, XQ-58 Valkyrie, and upcoming designs like Europa by Helsing.

| Category | Parameter to Specify | Typical Acceptance Target (Example) | Evidence / Deliverable |

|---|---|---|---|

| Workmanship | Assembly class | IPC-A-610 Class 3 (or Class 2 as agreed) | Inspection criteria + final inspection record |

| Soldering | Solder process standard | J-STD-001 (class per program) | Process profile + operator/process control record |

| Traceability | Build traceability | Serial/lot traceable (board + critical components) | Traceability report (serial ↔ lot/date code) |

| Sourcing | Component authenticity | Authorized channels; controlled alternates | AVL/CoC + alternates approval log |

| ESD | ESD handling | ESD controls enforced end-to-end | ESD checklist + packaging photos |

| Moisture | MSL handling | Bake/dry-pack per component MSL | Bake logs + MBB/label photos |

| AOI | Optical inspection coverage | 100% AOI scan (or defined sampling) | AOI report/summary + defect map |

| X-ray | Hidden joint screening | X-ray for BGA/QFN/large thermal pads | X-ray images + disposition notes |

| Rework | Rework policy | Rework limits + reinspection rules | Rework log + post-rework AOI/X-ray |

| Cleanliness | Ionic contamination | Target threshold defined (program dependent) | Cleanliness test report (if required) |

| Conformal coat | Coating requirement | Material/type/thickness/masking defined | Coating report + photos + cure record |

| Potting | Potting requirement | Material + coverage + cure defined | Potting record + photos |

| Connectors | Connector retention | Mechanical checks defined | Pull/fit check record (as specified) |

| RF | Controlled impedance | Target impedance + tolerance defined | Stackup confirmation + test coupon (if required) |

| Thermal | Thermal control | Hot spot mitigation plan | Thermal notes + inspection checklist |

| ICT | In-circuit test | Coverage % defined if used | ICT logs + fixture ID |

| FCT | Functional test | Pass/fail + measured outputs defined | FCT report + measurement logs |

| Firmware | Programming control | Version control + checksum policy | Programming log + version record |

| Packaging | Shipment packaging | ESD + moisture + shock protections | Packaging checklist + shipment photos |

| Documentation | Deliverable pack | DFM + CoC + test + traceability | “Procurement proof pack” PDF bundle |

If your next step is to integrate or source high-reliability PCBA electronics for UAV / UCAV platforms, HCJMPCBA can support key functions—especially in aerospace-grade manufacturing, EMI / shielding, miniaturization, thermal and vibration resilience.

To explore how advanced PCBA / PCB services can support aerospace / defense electronics in unmanned platforms, contact Guangzhou Huachuang Precision Technology (HCJMPCBA).

This article provides an in-depth exploration of PCBA technology, its evolution, key processes, chal

A budgetary quote is a preliminary cost estimate used during early PCBA development to assess feasib

Discover the 7 powerful strategies to evaluate and select the best Automotive PCB Fabrication & Asse