Leaded Solder vs Lead-Free Solder: What They Are & 6 Practical Ways to Distinguish Them

Learn the difference between leaded solder and lead-free solder material, including their compositio

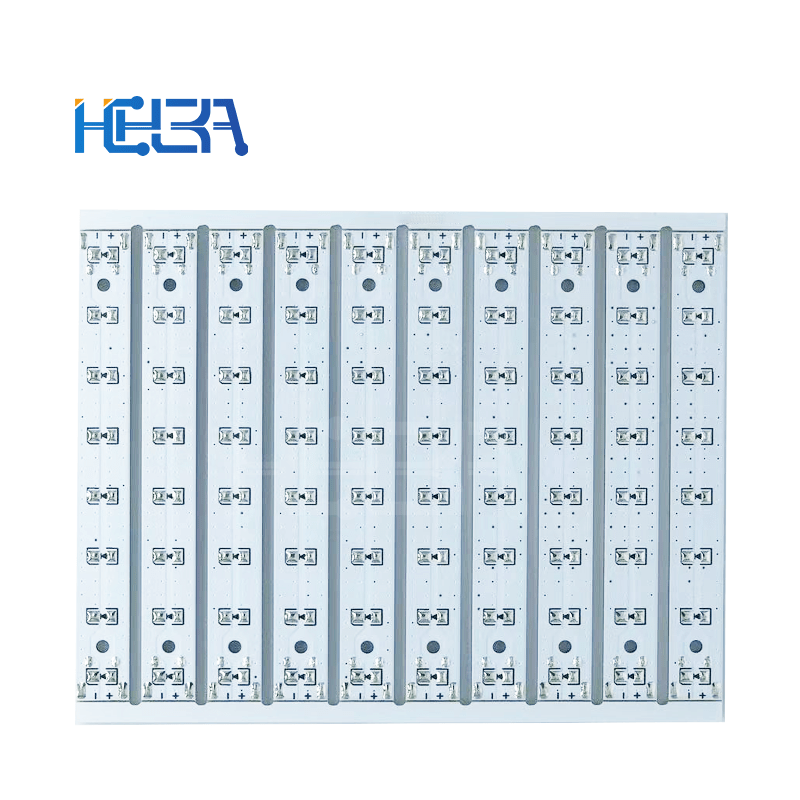

What Is an LED PCB Board? Complete Guide to LED Printed Circuit Board Design & Manufacturing

Table of Contents

ToggleAn LED PCB board, often referred to as an LED printed circuit board, led pcb, or led light pcb board, is the essential backbone used to connect and support LED components while managing heat and delivering electrical connectivity. Understanding what is led pcb, how to design it, and the practical steps to make an LED PCB board is vital for modern OEM engineers, procurement specialists, and end users seeking high-performance LED solutions.

This guide provides a detailed overview of led pcb board design, material selection, manufacturing considerations, and key advantages, helping you make informed decisions and accelerate your projects with efficient, reliable LED circuit board solutions.

An LED PCB board is specifically engineered to mount LED components—whether in rigid, flexible, or hybrid configurations. Unlike general-purpose PCBs, these boards prioritize thermal management, compact layout, and customized light control.

In essence, led pcb board design ensures that LED stripes or modules are electrically linked while dispersing heat effectively, which is critical for longevity and consistent lighting output.

Aluminum-based PCBs, or metal-core LED PCBs, are widely used for their excellent thermal conductivity. A thin dielectric layer separates the copper circuitry from the aluminum base, enabling efficient heat dissipation for high-power applications. ([turn0search4], [turn0search7])

FR-4 (fiberglass epoxy) PCBs are suitable for low-power LED boards like indicator lights or small decorative strips. Although less heat-efficient than aluminum, they are cost-effective and reliable for basic applications.

Constructed with polyimide or similar flexible materials, these led light pcb types are ideal for curved or tight-space applications such as wearable lighting or architectural installations.

Combining different materials or multiple layers, these custom custom led board designs support complex lighting circuits, LED drivers, and ensure compact integration in advanced LED systems.

A successful led pcb board manufacturing workflow involves multiple precise steps:

Incorporate heat sinks, copper fill, and thermal vias to optimize heat conduction. Strategic layout helps maintain LED efficiency and reduces failure risk.

Choose substrates such as aluminum or FR-4 based on power density, cost, and flexibility needs. Multilayer options enhance functionality without sacrificing performance.

Mount SMD LEDs and related led pcb components precisely using pick-and-place machinery or manual methods tailored to prototyping or high-volume runs.

Apply finishes like HASL or ENIG for reliable solder joints, especially in high-wattage designs where thermal and mechanical stress is significant.

Implement both visual and electrical testing to detect thermal defects, open circuits, or poor solder quality. This guarantees durability and performance.

(1)Superior Heat Dissipation: Metal-core boards offer effective heat transfer, preventing thermal buildup.

(2)Compact and Lightweight Design: Power-dense designs enabling sleek form factors.

(3)Energy Efficiency & Durability: Optimized circuits improve lifespan and reduce power consumption.

(4)Customization: Easily integrate features like RGB control (rgb pcb led) and flexible designs.

(5)Environmental Benefits: LED PCBs are mercury-free, RF-free, and often recyclable.

(1)Architectural/Industrial Lighting (indoor/outdoor)

(2)Commercial Displays & Signage

(3)Automotive Lighting

(4)Medical Devices & Wearables

Each application demands tailored led light pcb design and material choices to meet safety, brightness, and reliability requirements.

(1)Ensure Thermal Relief & Layout Balance – Avoid hot spots, use thermal vias effectively.

(2)Follow DFM Guidelines – Make solder pads accessible and avoid margins too close to edges.

(3)Maintain Stack-Up Consistency – Particularly critical in multilayer LED PCB designs.

(4)Surface Finish Selection – ENIG offers better integrity for fine-pitch designs than HASL.

(5)Materials Matching – Coefficient of thermal expansion differences can cause delamination; choose accordingly.

To source robust custom led pcb solutions, look for providers offering rapid custom quotes, multiple substrate choices, and assembly services. At HCJMPCBA, we offer tailored LED PCB board design, prototyping, and high-quality PCBA services with competitive lead times and attention to thermal and engineering requirements.

Q: What is an LED PCB?

A: A printed circuit board designed specifically for mounting LEDs and associated circuitry.

Q: What materials are used?

A: Aluminum (for high power), FR-4 (for low power), flexible (for curved designs).

Q: How to design for heat management?

A: Use metal substrates, thermal vias, and proper layout spacing.

Q: Can LED PCBs be customized?

A: Yes. Materials, board shape, driver integration, and LED types are all customizable options.

Q: Where to buy quality LED PCBs?

A: Partner with companies like HCJMPCBA for comprehensive manufacturing and assembly support.

An LED PCB board is more than a simple base—it ensures efficient heat management, compactness, and reliability in enlightened designs. From material selection to layout, assembly, and testing, each step influences performance and durability. Whether you’re integrating RGB strips, medical lighting, or high-output fixtures, choosing the right design and trusted OEM partner is essential.

To learn more about PCBA services, please contact Guangzhou Huachuang Precision Technology.

Learn the difference between leaded solder and lead-free solder material, including their compositio

Discover what PCBA assembly is, why it matters in modern electronics, and explore the 7 most common

Discharging capacitors is a critical safety and quality control step in electronics and PCBA work. T