Unlocking Innovation with Guangzhou Huachuang Precision Technology Co., Ltd.

Guangzhou Huachuang Precision Technology Co., Ltd. offers fast, high-quality PCBA solutions with a f

9 Practical Essentials of IPC-TM-650: What It Is, How IPC Testing Works, and How to Turn Test Methods into Verifiable PCB/PCBA Quality Evidence

Table of Contents

ToggleIn global supply chains, quality disputes rarely start with “no test was performed.” They start with unclear test language:

One party says “passed IPC testing,” but the method number and revision are missing.

The same board is tested by two labs, and the results cannot be compared.

A “thermal stress test” is requested, but sample preparation, coupons, and acceptance rules were never aligned.

This is where IPC-TM-650 becomes valuable. It provides a structured library of test methods for printed circuit boards (PCBs) and related materials across chemical, mechanical, electrical, and environmental validation—so teams can specify tests in a way that is repeatable, comparable, and audit-friendly.

For OEM engineers, it helps translate product requirements into testable statements. For procurement decision-makers, it reduces supplier risk by enabling apples-to-apples verification evidence. For end customers, it increases confidence that a PCB/PCBA build was validated using consistent procedures—not vague claims.

IPC-TM-650 is IPC’s test methods manual: a curated set of standardized procedures used to evaluate printed boards, their materials, and related processes through chemical, mechanical, electrical, and environmental testing. It helps teams turn quality requirements into specific, reproducible test method references—including method number, revision, conditions, and evidence—so results can be verified and compared across suppliers and labs.

This guide is maintained by the HCJMPCBA engineering team and updated with production checklists.

1.IPC-TM-650 is a method library, not a single test—precision comes from selecting the right method family and locking execution conditions.

2.The “secret” of reproducible results is documentation: method number + revision + sample definition + conditions + raw data.

3.The best programs use IPC testing to close the loop: test results feed back into manufacturing controls and supplier alignment, not just end-of-line acceptance.

IPC-TM-650 is a published manual from IPC that consolidates test procedures used to validate printed boards, connectors, and related materials. The methods cover multiple categories—chemical, mechanical, electrical, environmental, visual, and dimensional—so that different organizations can run tests using a consistent procedure language and produce comparable evidence.

In practical procurement terms: IPC-TM-650 helps prevent the phrase “we ran an IPC test” from becoming meaningless. It turns that phrase into something verifiable, such as:

exact method reference

current revision/status

sample plan and preparation rules

test conditions

pass/fail criteria

raw measurement outputs and traceability

It is not a single “certificate” that proves a board is good. It’s a set of procedures you can use to verify specific characteristics.

It is not automatically an acceptance standard by itself. Acceptance needs a defined criterion (often derived from contract specs, product requirements, or referenced standards).

It is not a guarantee that two labs will match if they run different revisions or different sample preparation steps. Reproducibility requires alignment.

IPC-TM-650 groups methods across broad technical categories (for example, environmental and electrical testing). This structure makes it easier to select the right family based on the risk you are trying to control—rather than randomly collecting tests.

A useful internal habit is to label each method you select with:

Risk it mitigates (failure mode)

What it measures (property)

How it is executed (method + conditions)

What evidence is produced (report contents)

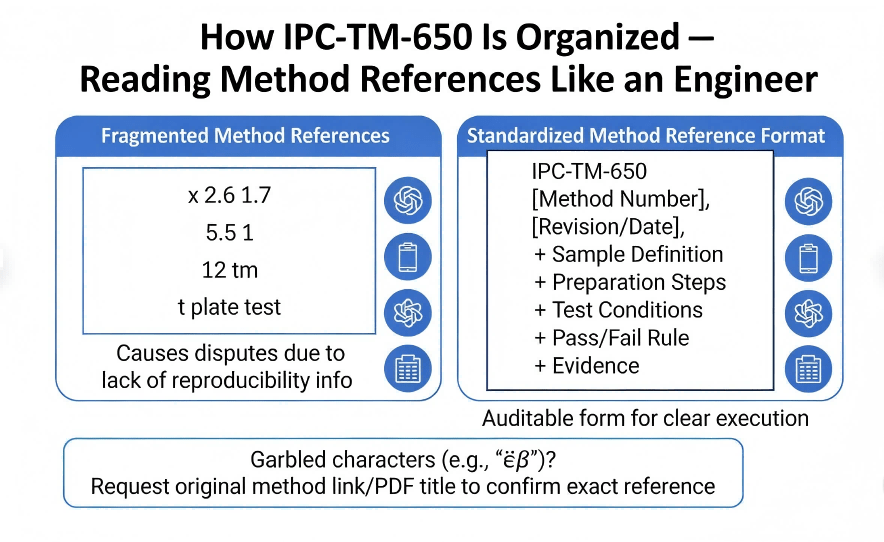

In real purchasing and engineering emails, method references often arrive as fragments such as:

“x 2.6 1.7”

“5.5 1”

“12 tm”

“t plate test”

These fragments cause disputes because they lack the information needed for reproducibility. A “method reference” should be upgraded into an auditable form:

Best practice reference format

IPC-TM-650 [Method Number], [Revision/Date], plus:

sample definition (coupon type, location, quantity)

preparation steps (cleaning, bake, conditioning)

test conditions (time, temperature, voltage, chemical concentration)

pass/fail rule or reporting threshold

If your team receives garbled characters (for example, “єь”) inside a spec or email, treat it as a transcription error and request the original method link or PDF title so you can confirm the exact reference.

How Ipc Tm 650 Is Organized Hcjmpcba

The table below is designed to be “forwardable” inside engineering and procurement threads. It focuses on how to choose what to do, not on memorizing the manual.

| Quality Risk / Failure Mode | What to Test (Goal) | IPC-TM-650 Method Family (by technical category) | Key Parameters to Lock | What Evidence to Require |

|---|---|---|---|---|

| Solder mask lifting / poor adhesion | Solder mask adhesion and robustness | IPC-TM-650 testing methods for solder mask (adhesion/tape-type procedures exist) | substrate finish, cure profile, test area definition, tape type/force, dwell time | method+revision, photos before/after, failure mode notes |

| Thermal cycling / copper cracking risk | Thermal stress test to reveal structural weaknesses | Environmental / thermal stress method family (example: thermal stress test references exist in IPC testing discussions) | ramp/soak conditions, coupon design, preconditioning, inspection criteria | method+revision, cycle profile, microsection/inspection outputs |

| Electrochemical migration / CAF risk | Propensity for electrochemical failure | Environmental/electrical reliability method family (CAF-related methods exist) | voltage bias, humidity, spacing, coupon geometry, duration | method+revision, bias conditions, failure definition, raw logs |

| Dimensional instability / warpage | Board geometry stability | Dimensional / mechanical method family | measurement approach, fixture, sampling locations, preconditioning | method+revision, measurement logs, equipment calibration |

| Cleanliness / ionic contamination | Residual contamination level | Chemical/cleanliness test method family | extraction method, solvent, time/temp, reporting units | method+revision, raw readings, lot traceability |

| Electrical integrity | Insulation performance / continuity | Electrical test method family | test voltage, dwell time, pass thresholds, sample count | method+revision, test conditions, pass/fail report |

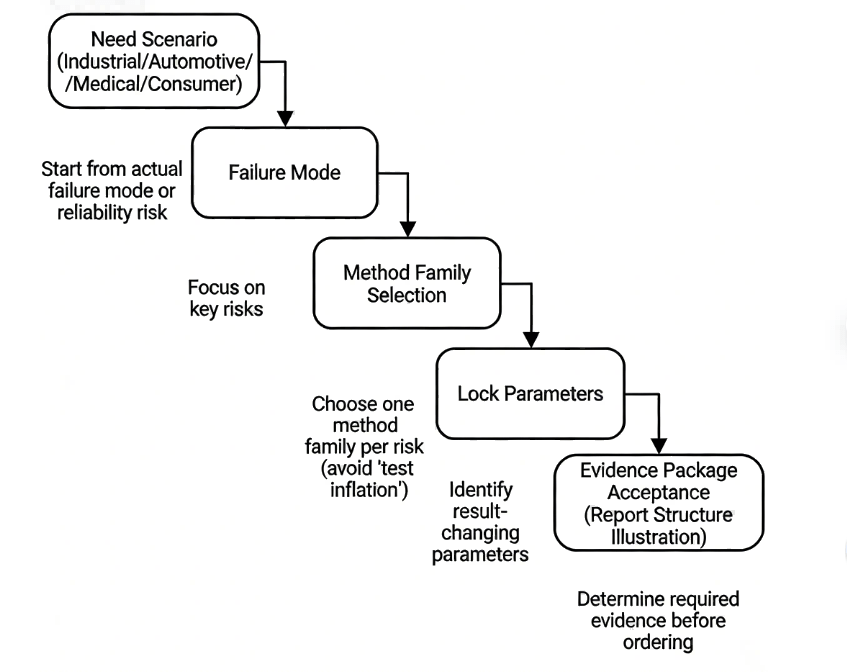

How to use this decision table

Start from the failure mode or reliability risk you actually care about.

Select one method family per key risk (avoid “test inflation” without intent).

Lock the parameters that change results.

Decide what evidence you need before you place the order.

How To Use This Decision Table Hcjmpcba

Instead of “high reliability,” translate into measurable statements:

What characteristic must be verified?

Under which conditions?

With what pass/fail rule?

How will it be documented and traced?

A good statement is measurable and leaves little room for interpretation.

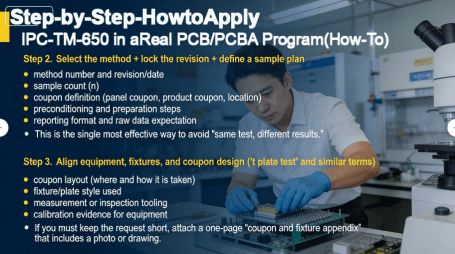

A method number alone is not enough. Your test request should specify:

method number and revision/date

sample count (n)

coupon definition (panel coupon, product coupon, location)

preconditioning and preparation steps

reporting format and raw data expectation

This is the single most effective way to avoid “same test, different results.”

Terms like “t plate test” often mean different fixtures or coupon styles across organizations. Even if the method procedure is standardized, fixtures and sample geometry can change outcomes.

Before testing, align:

coupon layout (where and how it is taken)

fixture/plate style used

measurement or inspection tooling

calibration evidence for equipment

If you must keep the request short, attach a one-page “coupon and fixture appendix” that includes a photo or drawing.

A professional IPC test report should not be “Pass.” It should include the pathway from method reference to data:

method and revision

conditions

sample identifiers

raw measurement outputs

photos/microsections where relevant

signature/approval fields

This aligns with IPC’s emphasis that test methods are advisory procedures and that users must apply them responsibly in context.

The highest-value use of IPC testing is to reduce future escapes:

If a solder mask adhesion issue appears, review cure profile, surface prep, and handling steps.

If thermal stress reveals risk, review drilling parameters, plating, and material selection.

If cleanliness trends worsen, review cleaning chemistry, rinse controls, and drying/bake steps.

Testing that never becomes process control is expensive documentation with limited value.

Use this table as a contract appendix or supplier alignment sheet. It is designed to be copy/paste friendly.

| Item | IPC-TM-650 Method No. | Revision / Date | Sample Definition (n, coupon, location) | Equipment / Calibration | Conditions (time/temp/voltage/chemistry) | Pass/Fail Criteria | Raw Data Attached | Photos / Microsections / Plots | Traceability (lot/batch/serial) |

|---|---|---|---|---|---|---|---|---|---|

| Solder mask adhesion check | (fill) | (fill) | (fill) | (fill) | (fill) | (fill) | Y/N | Y/N | (fill) |

| Thermal stress test | (fill) | (fill) | (fill) | (fill) | (fill) | (fill) | Y/N | Y/N | (fill) |

| Cleanliness / ionic residues | (fill) | (fill) | (fill) | (fill) | (fill) | (fill) | Y/N | Y/N | (fill) |

| Electrical integrity | (fill) | (fill) | (fill) | (fill) | (fill) | (fill) | Y/N | Y/N | (fill) |

| Reliability screening | (fill) | (fill) | (fill) | (fill) | (fill) | (fill) | Y/N | Y/N | (fill) |

How this table reduces procurement risk

It prevents “method drift” between suppliers.

It forces alignment on conditions and evidence, not just outcomes.

It makes acceptance auditable across lots and reorders.

How To Apply Ipc Tm 650 In A Real Pcb Pcba Program Hcjmpcba

Solder mask issues often show up late: assembly defects, cosmetic rejects, or field exposure problems. A solder mask method request should clarify:

what surface finish is present under the mask

cure process and handling assumptions

the exact adhesion/robustness procedure reference and revision

how failures are documented (photos, peel behavior, location mapping)

Even for experienced teams, solder mask testing becomes inconsistent when documentation is incomplete. Adhesion-type solder mask procedures are documented in IPC test method references.

Thermal stress tests are common in reliability screening, but comparability collapses when:

the temperature profile is described loosely

coupon design is not aligned

inspection definition is inconsistent

In some industry discussions, thermal stress test data is used as an early warning correlated with manufacturing risks such as copper cracking. The point is not the correlation itself; the point is that the test becomes valuable only when it is executed and recorded consistently.

HCJMPCBA supports PCB and PCBA programs by aligning test language with build controls and documentation. A verification-focused workflow typically includes:

Review drawings and acceptance requirements to identify which characteristics should be verified by method-based evidence

Confirm what “evidence” means for the program (raw data, photos, traceability, approval signatures)

Process checkpoints that map to verification risks (handling, cure, cleanliness, material control)

Traceability fields that allow you to connect test results back to lots and process windows

Reports structured around method reference + conditions + sample definition + raw data

A consistent evidence pack format so reorders are comparable rather than “new interpretations”

Stating “IPC-TM-650” without the method number and revision, making results impossible to reproduce.

Reporting only “Pass/Fail” without raw data, conditions, or sample plan—no one can verify it later.

Ignoring sample preparation differences (cleaning, baking, conditioning), then wondering why labs disagree.

Treating fixture terms (like “t plate test”) as universal without aligning coupon geometry and tooling.

Copy/paste errors (including garbled text such as “єь”) entering a specification—then the wrong method is executed.

1) Is IPC-TM-650 mandatory for every PCB/PCBA project?

Not always. Many projects do well with a focused set of methods targeted at the program’s real risks. IPC-TM-650 helps you define those tests clearly; whether you must use it depends on customer requirements and contract language.

2) Why can two labs run “the same test” and get different results?

Because the method reference may be incomplete: different revision, different sample preparation, different coupon geometry, different conditions, or different interpretation of pass/fail. Locking the full reference format dramatically reduces this gap.

3) What should an audit-ready IPC test report include?

At minimum: method number + revision/date, sample definition (n and location), conditions, equipment/calibration reference, raw data, and traceability. The verification table in this article is a practical template.

4) How does IPC-TM-650 help with solder mask control?

It provides standardized procedures for evaluating solder mask behavior (including adhesion-type procedures), and—more importantly—it provides a common way to report and compare results across lots and suppliers.

5) What is the fastest way to start using IPC-TM-650 without overspending?

Start with a decision table: choose one method family per key risk (solder mask, cleanliness, electrical integrity, thermal stress where needed). Then enforce the verification table format so evidence stays comparable.

6) How should procurement teams write an IPC test requirement in a purchase order?

Use a short appendix: method reference format + sample plan + required evidence pack. Avoid phrases like “IPC test required” without method numbers and conditions.

7) Does IPC-TM-650 replace in-process manufacturing controls?

No. It complements them. The best programs use method-based evidence to validate controls and prevent repeat failures, not just to create paperwork.

Evidence You Can Request (Practical Risk-Reduction Pack)

Below is a vendor-neutral checklist you can request to reduce ambiguity during acceptance and reorders.

Evidence you can request from HCJMPCBA

A method list aligned to your top risks (with method number + revision fields)

Sample plan template (coupon definition, n, locations, preparation notes)

Report structure template (conditions + raw data + traceability + approvals)

Example evidence pack index (what files you receive, naming conventions, retention)

Traceability mapping format (how test results link to lots/batches/serials)

Guangzhou Huachuang Precision Technology Co., Ltd. offers fast, high-quality PCBA solutions with a f

Guangzhou Huachuang Precision Technology ensures high PCBA reliability through advanced SMT and BGA

In the field of electronics manufacturing, PCB Layout (Printed Circuit Board Layout) is a core aspec