What Is a Gerber File? — Complete Guide for PCB / PCBA Professionals

Discover what a gerber file is, why it is the universal “language” for PCB manufacturing, how to

15 Expert Insights: What Does a Flame Sensor Do? How It Works & PCBA Integration Mastery

Table of Contents

Toggle

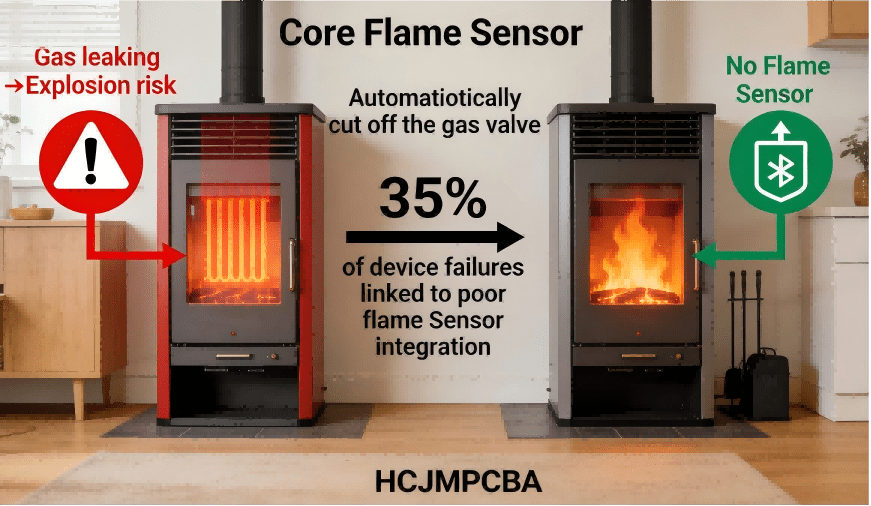

Schematic Diagram Of The Core Functions Of A Flame Sensor

Flame Verification: Confirms that fuel ignites successfully (e.g., in a furnace or water heater) and remains lit during operation.

Emergency Shutdown: Triggers the gas valve furnace to close immediately if no flame is detected, cutting off fuel supply.

Fault Signaling: Alerts control systems to abnormal conditions (e.g., weak flame, sensor contamination) that could compromise safety.

Efficiency Optimization: Ensures consistent combustion by monitoring flame stability, reducing energy waste and emissions.

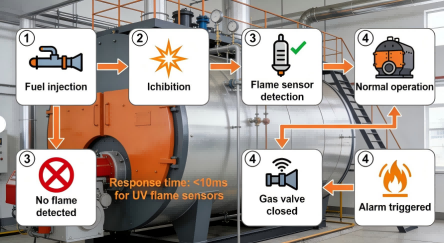

Flowchart Of Flame Sensor Functions

The sensor’s UV tube contains a gas that ionizes when exposed to flame UV radiation.

Ionization allows a small current to flow through the tube, signaling the presence of a flame.

Most UV sensors include a 2–3 second time delay to avoid false alarms from lightning or welding arcs .

Ultra-fast response time (<10ms) for critical safety applications (e.g., gas turbines, Torch System).

High selectivity—ignores non-flame light sources, reducing false alarms .

Ideal for clean-burning fuels like natural gas and propane.

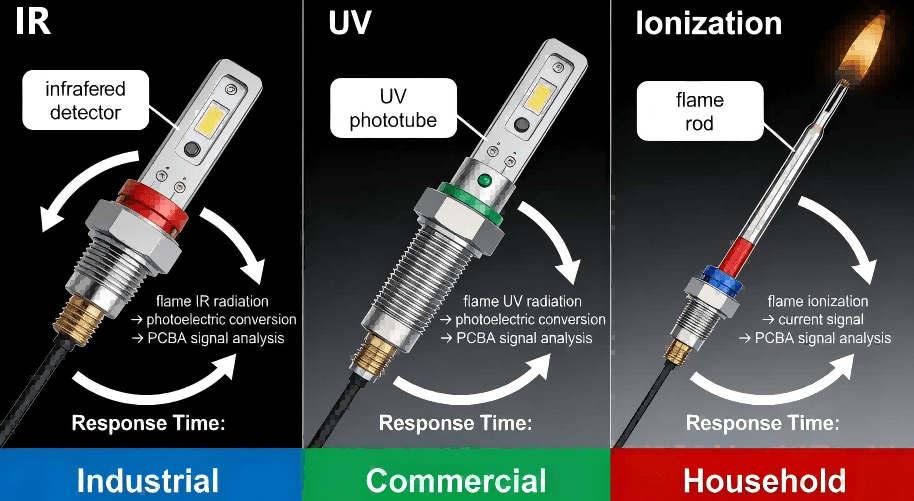

The sensor’s metal rod (flame rod) extends into the furnace flame.

The PCBA sends a small AC current through the rod; the flame’s ions convert this AC current to DC.

The control system detects the DC current as proof of a valid flame. If no current is detected (no flame), the gas valve closes.

Low cost and simple design, perfect for consumer appliances.

Direct integration with standard furnace PCBA systems.

Comparison Diagram Of The Working Principles Of Three Flame Sensors

| Type | Detection Principle | Ideal Applications | PCB/PCBA Integration Needs | HCJMPCBA Expert Tip |

|---|---|---|---|---|

| Infrared (IR) | Detects IR radiation from flame carbon particles | Industrial boilers, coal furnaces, incinerators | Thermal management (heat sinks for high temps), filtered power supply to reduce noise | Use IPC 6012 Class 3 standards for high-reliability industrial PCBA |

| Ultraviolet (UV) | Detects short-wave UV from flame reactions | Gas turbines, propane heaters, aerospace systems | Fast-signal processing circuits, ESD protection (UV tubes are sensitive to voltage spikes) | Integrate 2ms time-delay filters to minimize false alarms |

| Ionization (Flame Rectification) | Flame converts AC to DC current | Residential furnaces, water heaters | Low-current sensing circuits, corrosion-resistant PCB surface treatment (ENEPIG) | Ensure flame rod wiring is shielded to avoid interference |

| Dual (IR/UV) Composite | Combines IR and UV detection for redundancy | Oil refineries, nuclear facilities, mission-critical systems | Dual-signal processing modules, fail-safe logic on PCBA | Use redundant power supplies to maximize uptime |

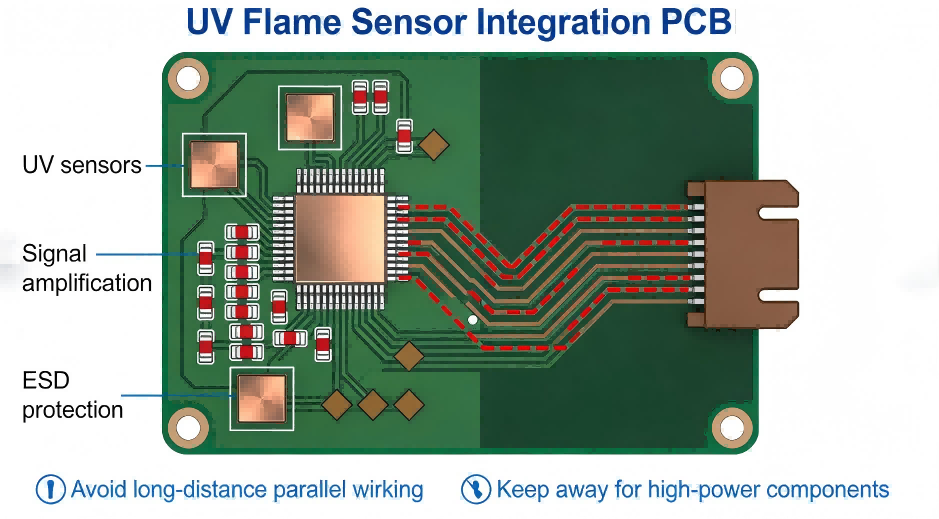

Signal Integrity: Flame sensor signals are often weak—PCB layouts must minimize noise with proper grounding (star ground) and short trace lengths .

Environmental Hardening: For industrial use, PCBA must resist moisture, dust, and extreme temperatures (use conformal coating and metal-core PCBs).

Compliance: Meet IEC 61508 (functional safety) and IPC 6012 (PCB quality) standards for global market access .

Pcbpcba Flame Sensor Integration Layout Diagram

Fast response time (<50ms) to shut off gas if flame is lost.

Low power consumption for battery-operated models.

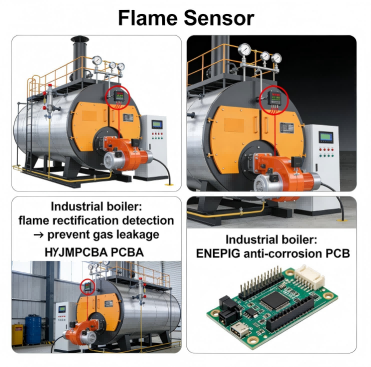

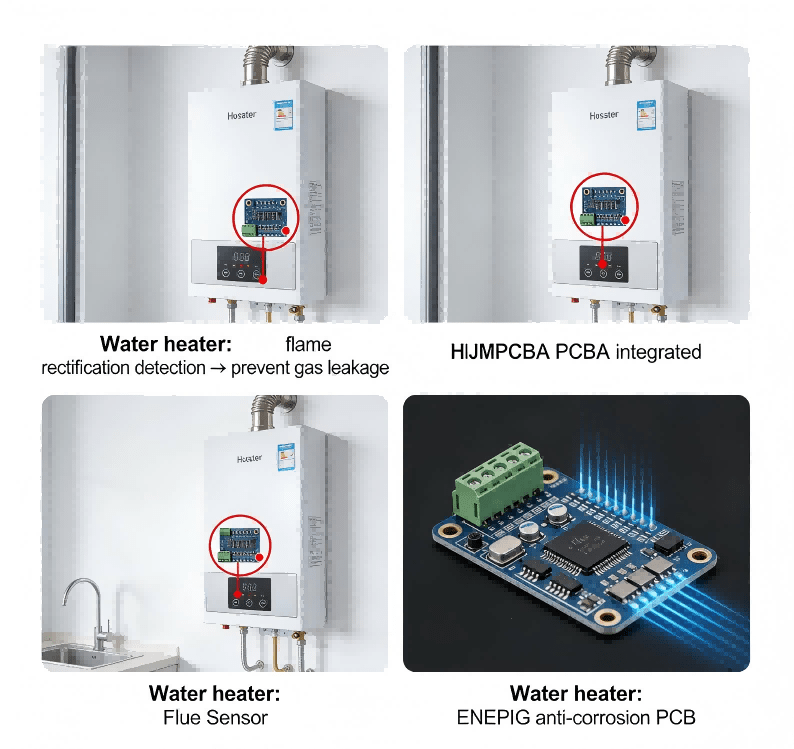

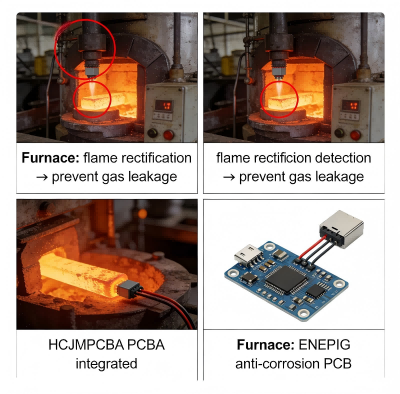

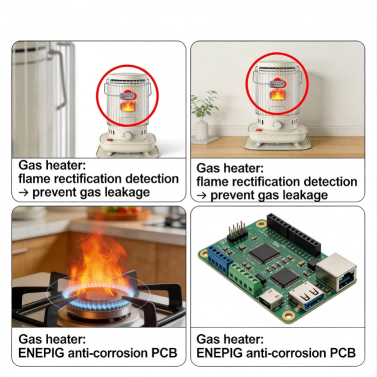

Functional Display Diagram Of Flame Sensors In Four Major Application Scenarios 1

Functional Display Diagram Of Flame Sensors In Four Major Application Scenarios 4

Functional Display Diagram Of Flame Sensors In Four Major Application Scenarios 3

Functional Display Diagram Of Flame Sensors In Four Major Application Scenarios 2

Disconnect power and gas supply to the device before testing.

Wear protective gear (gloves, goggles) to avoid burns or electrical shock.

Check the sensor rod (ionization type) for corrosion, dust, or damage—clean with a soft brush if dirty.

Inspect PCB wiring for loose connections, fraying, or short circuits .

Verify the sensor is positioned correctly (aligned with the flame path).

For Ionization (Furnace) Sensors:

Set the multimeter to measure microamps (μA).

Disconnect the sensor wire from the PCBA control board.

Connect the multimeter probes in series between the sensor and the wire.

Reconnect power and ignite the furnace—normal readings range from 1–10 μA .

If no reading: Replace the sensor or check for PCB wiring issues.

For IR/UV Sensors:

Set the multimeter to measure voltage (DC 0–5V).

Connect probes to the sensor’s signal output pins on the PCBA.

Expose the sensor to a flame (e.g., lighter) from 10–15cm away.

A valid signal will show a voltage drop (0.5–2V) on the multimeter .

No voltage change: Test the sensor’s power supply on the PCBA (typically 12V or 24V DC).

| Issue | Cause | HCJMPCBA PCB/PCBA Fix |

|---|---|---|

| False Shutdowns | Signal interference or dirty sensor | Integrate noise filters and self-cleaning logic into PCBA |

| No Flame Detection | Misalignment or faulty wiring | Design PCB with sensor positioning guides and continuity checks |

| Short Sensor Lifespan | High temperature or moisture | Use metal-core PCBs and conformal coating for environmental protection |

| Error Codes (e.g., Traeger 0024/0031) | Loose connections or firmware bugs | Implement PCB connector locks and over-the-air (OTA) firmware updates |

Schematic Diagram Of Flame Sensor Testing Process

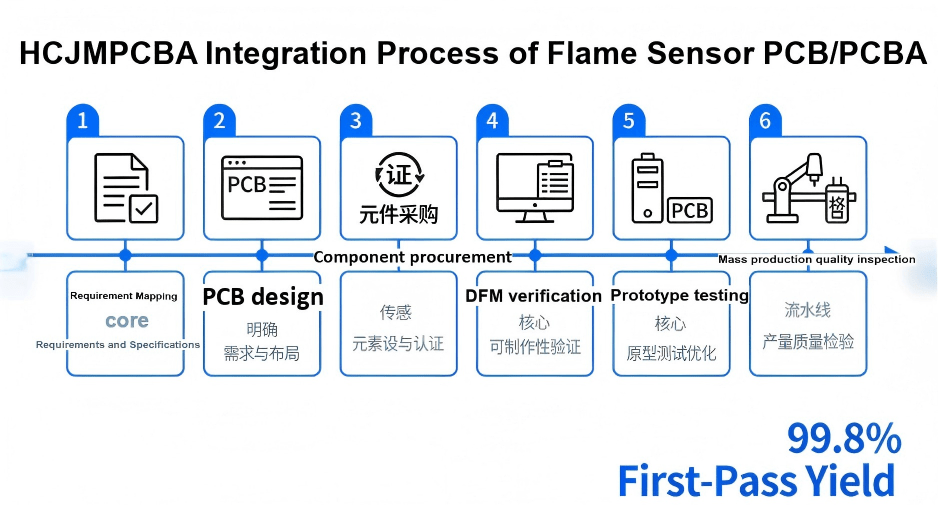

Collaborate with your team to define key parameters: sensor type (IR/UV/ion), operating temperature, response time, and compliance standards (IEC 61508, IPC 6012).

Conduct a failure modes and effects analysis (FMEA) to identify potential integration risks (e.g., signal noise, thermal stress) .

Component Placement: Position the flame sensor connector near the edge of the PCB for easy access; keep signal amplification circuits close to the sensor to minimize noise.

Trace Routing: Use short, wide traces for sensor signals (minimize resistance); implement ground planes to reduce electromagnetic interference (EMI) .

Thermal Management: Add thermal vias and heat sinks for high-temperature applications (critical for IR sensors in industrial boilers).

Source genuine flame sensors from ISO-certified suppliers (HCJMPCBA’s supply chain includes Honeywell, Siemens, and custom-manufactured sensors).

Test all components for sensitivity, response time, and durability before integration.

Use automated DFM tools to check for soldering issues, trace width compliance, and component compatibility.

Conduct manual reviews by HCJMPCBA’s senior engineers to catch edge cases (e.g., EMI from nearby power components).

Build functional prototypes to test flame sensor performance in real-world conditions (temperature cycling, humidity, vibration).

Validate PCB/PCBA with flame simulation tools to ensure response time meets safety requirements.

Manufacture PCBA in ISO 9001-certified facilities using pick-and-place machines for precision.

Conduct 100% functional testing (flame detection accuracy, signal integrity, emergency shutdown response) before shipment.

Hcjmpcba Flame Sensor Pcbpcba Integration Flowchart

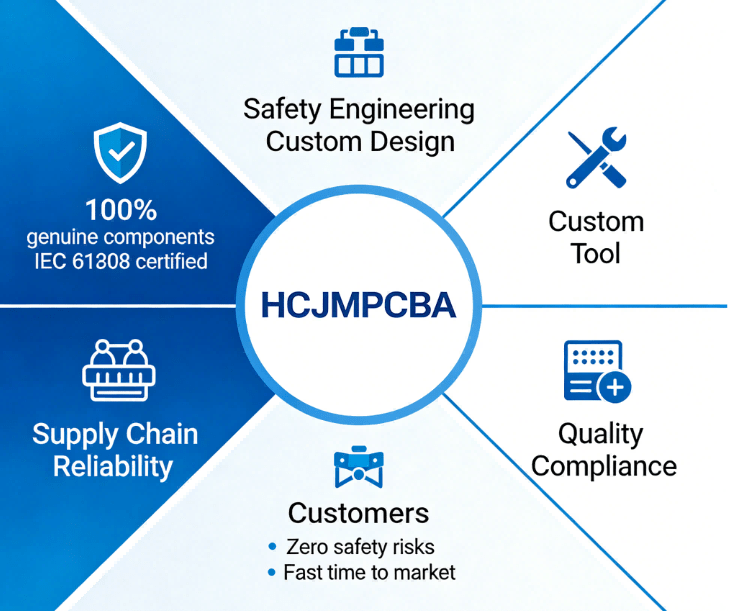

Our engineers are certified in IEC 61508 (functional safety) and IPC 6012 (PCB standards), ensuring flame sensor integration meets global safety requirements.

We implement redundant circuits in mission-critical applications (e.g., industrial boilers) to eliminate single points of failure.

Whether you need a compact PCB for a portable gas heater or a rugged PCBA for a nuclear facility, we tailor designs to your specific needs.

Our in-house lab can simulate extreme environments (temperature, humidity, vibration) to validate performance.

We source 100% genuine flame sensors and components from trusted suppliers, with no counterfeits—critical for safety devices.

Our inventory includes hard-to-find sensors (e.g., UV flame sensors for aerospace) and offers 48-hour lead times for urgent orders.

ISO 9001 and IPC 6012 Class 3 certification ensures PCBA meet the highest quality standards.

Every batch undergoes flame detection accuracy testing, signal integrity analysis, and environmental stress screening.

From pre-design consultation to post-delivery technical support, our team is available to address questions and resolve issues.

We provide detailed documentation (schematic diagrams, test reports) to simplify your certification process.

Hcjmpcba Capability Display Infographic

Conducted FMEA to identify root causes: signal noise from poor PCB layout, low-quality components, and inadequate thermal management.

Redesigned the PCB with:

Sourced genuine IR flame sensors from Honeywell with a 10-year lifespan.

Implemented IEC 61508-compliant redundant circuits for fail-safe operation.

Failure rate dropped to 0.2% (well below industry average).

The OEM achieved EU safety certification and expanded into new markets.

Cost savings of 35% from reduced recalls and maintenance.

Q1: What is a flame supervision device?

A flame supervision device (FSD) is a system that includes a flame sensor, control board, and gas valve. It monitors flame presence and shuts off fuel if the flame is lost—common in furnaces, boilers, and commercial kitchens.

Q2: How does a furnace flame sensor work differently from an industrial one?

Furnace flame sensors (ionization type) use flame rectification for cost-effectiveness, while industrial sensors (IR/UV) prioritize durability, long-range detection, and resistance to harsh environments.

Q3: How often should a flame sensor be tested?

For residential devices: Annually during maintenance. For industrial equipment: Monthly, or as part of a predictive maintenance program. HCJMPCBA’s PCBA includes self-testing logic to reduce manual checks.

Q4: Can a faulty PCB cause flame sensor issues?

Yes—common PCB-related issues include: weak power supply to the sensor, signal noise, loose connections, and faulty amplification circuits.

Q5: What compliance standards are required for flame sensor PCBA?

Key standards include IPC 6012 (PCB quality), IEC 61508 (functional safety), and regional standards (e.g., UL for North America, CE for Europe).

Discover what a gerber file is, why it is the universal “language” for PCB manufacturing, how to

Discover what schematics are and how to read electrical schematics effectively. This guide explains

Learn how to clean battery corrosion in remote control devices and other electronics with safe, step