7 Key Principles: What Is an 8-Layer PCB Stackup and How to Design It Right

Discover what is an 8 layer pcb stackup, best layer configurations, materials, signal integrity stra

12 Key Differences Between Active and Passive Components: A Complete Guide for PCBA Professionals

Table of Contents

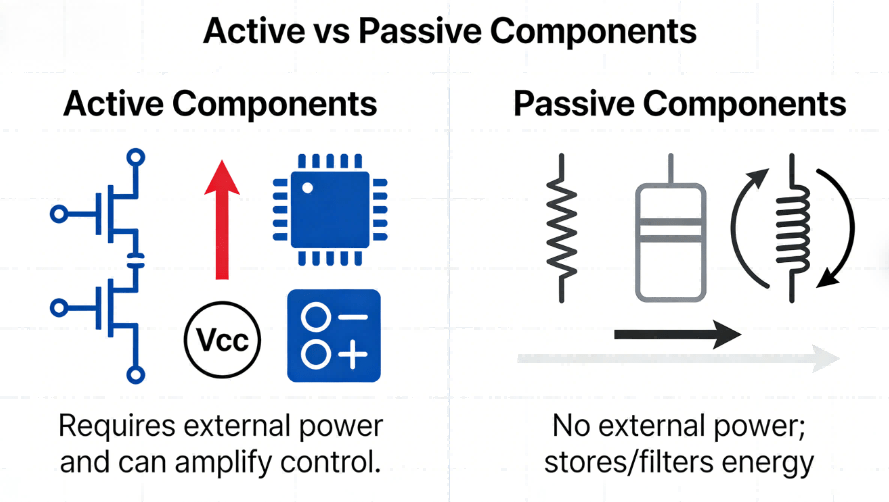

ToggleIn printed circuit board assembly (PCBA), every electronic function depends on the performance of its building blocks: components that either control or support electrical energy. For OEM engineers, procurement decision makers, and end customers, misidentifying or misselecting active and passive components can lead to costly failures — from signal distortion in industrial controllers to power inefficiencies in automotive electronics. Active components perform operations that amplify, switch, or regulate electrical signals, while passive components store, filter, or dissipate energy without external power (per standard electronics definitions).

This guide demystifies “what is the difference between passive and active components,” answers the common question “why are some inductors active while others passive?”, and showcases how HCJMPCBA streamlines component selection, sourcing, and risk mitigation for global PCBA projects.

Active components are the dynamic elements in PCBA — they require an external power supply to operate, and they have the ability to control or amplify electrical signals within a circuit. Without external power, they simply cannot perform their intended function. In practical engineering classification:

Active components may provide power gain and can change signal behavior.

They often contain semiconductor materials (e.g., silicon) that enable these advanced functions.

Active components play “smart” roles in electronic systems — they control, amplify, switch, regulate, or generate signals. Some examples include:

Transistors (BJT, MOSFET, FET)

A transistor has three terminals and can control large current flows with a smaller input signal. This ability to amplify or switch signals is foundational in PCBA logic, power management, and sensor interface design — from mobile IoT boards to industrial control units.

Integrated Circuits (ICs)

These complex active components combine many transistors and supporting elements to perform defined functions — microcontrollers, analog front-ends, voltage regulators, RF transceivers. ICs are central to modern electronic products and systems.

Operational Amplifiers (Op-Amps)

Used for precision signal amplification and conditioning, op-amps are active elements that require power and can significantly shape signal integrity in sensor interfaces, audio circuits, and control loops.

Passive components are stable elements in PCBA. Unlike active components, they do not require an external power source, cannot provide power gain, and typically do not control signal behavior beyond storing, filtering, or limiting energy. They influence system behavior by shaping how energy flows through the circuit.

Resistors

Resistors limit current flow and are often used for voltage dividing, setting bias points, and controlling signal strength. They follow Ohm’s Law and are linear in behavior.

Capacitors

Capacitors store electrical energy in an electric field. They are critical for power filtering, decoupling noise, and forming timing networks.

Inductors

Inductors store magnetic energy when current flows through a coil. They are commonly used in power supply filtering and EMI suppression

| Passive Component | Key PCBA Application |

|---|---|

| Resistors | Current limiting, voltage dividers |

| Capacitors | Power smoothing, signal coupling |

| Inductors | Energy storage, EMI suppression |

| Transformers | Voltage conversion and isolation |

To support structural search visibility and Google Featured Snippets, here’s a comparative summary:

| Aspect of Difference | Active Components | Passive Components |

|---|---|---|

| External Power Need | Required | Not required |

| Power Gain | Capable (can amplify) | Incapable (cannot amplify) |

| Current/Voltage Control | Yes | No |

| Energy Behavior | Deliver/modify energy | Store/dissipate energy |

| Linearity | Often non-linear | Mostly linear |

| Complexity | Semiconductor-based | Simple physical structure |

| Cost | Relatively higher | Lower |

| Failure Sensitivity | Higher | Lower |

| Calibration Needed | Often | Rarely |

| Typical PCB Role | Signal control & switching | Support & stabilization |

| Example Use | Amplification, logic | Filtering, current limiting |

| Design Impact | Requires careful supply management | Stable and predictable behavior |

Tip: For PCBA professionals, the most critical distinction is power gain and control capability — active components drive functional behavior, while passive ones ensure that behavior is stable and energy is managed predictably.

Hcjmpcba Active Vs Passive Components

Hcjmpcba Inductor Active Vs Passive

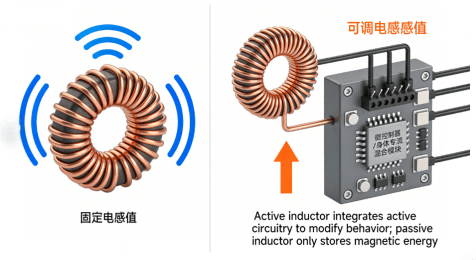

4. FAQ: Why Are Some Inductors Active While Others Passive?

A frequent engineering confusion is why some inductors are referred to as “active” even though inductors are typically passive devices.

What Makes a Passive Inductor?

A passive inductor is simply a coil of wire (possibly with a magnetic core). It stores energy in a magnetic field and does not require external power or added control — its inductance is fixed and determined by physical design.

What Makes an Inductor “Active”?

An active inductor is a more complex circuit: it combines a passive coil with active circuitry (e.g., transistor networks or integrated tuning circuits) that can dynamically control effective inductance or behavior. This additional circuitry requires an external power supply and provides functions such as frequency tuning or gain, which passive inductors cannot do.

In PCBA, designers might choose active inductors for RF tuning or adaptive filtering, while passive inductors remain a staple for power supply filtering and EMI suppression.

For PCBA procurement leaders, the two biggest challenges are quality assurance and risk mitigation. HCJMPCBA’s component sourcing and validation framework addresses these directly with a four-step process:

Step 1: Requirement Analysis

HCJMPCBA engineers work with clients to define functional requirements — from voltage/current specs of active electronic components to the tolerance and environment ratings of passive electrical components.

Step 2: Global OEM Sourcing & Validation

We partner with major manufacturers (TI, Murata, Vishay, etc.) to source authentic active and passive parts. Each batch undergoes verification (e.g., X-ray authentication and material verification) to prevent counterfeit risks.

Step 3: Inventory & Fast Delivery

With a stocked portfolio of 100,000+ components, HCJMPCBA ensures rapid fulfillment — vital for reducing production delays.

Step 4: Post-Delivery Support

Traceable batch reports and replacement guarantees provide confidence even through PCBA testing cycles.

Certifications: ISO 9001 and IATF 16949 compliance.

Case Studies: From automotive RF modules requiring active inductors to medical devices needing stable passive filters, HCJMPCBA has supported 500+ global clients.

Cost Advantage: Regional sourcing reduces component costs substantially versus local suppliers.

Q1: What is passive components?

Passive components operate without external power, store or dissipate energy, and do not amplify signals — examples include resistors, capacitors, inductors, and transformers.

Q2: Why is it referred to as passive?

They are called “passive” because they respond to electrical signals rather than actively modify or control them.

Q3: What is a passive device in a car?

In automotive PCBA, common passive devices are resistors for current limiting, capacitors for noise filtering, and inductors for suppressing EMI.

Q4: What are active components of electronics in PCBA?

Common active components include transistors, op-amps, microcontrollers, and ICs — elements that amplify, switch, or regulate signals.

Q5: How do active and passive devices differ in linearity?

Active devices often show non-linear behavior, while passive devices tend to be linear (following predictable relationships like Ohm’s Law).

Understanding the difference between active and passive components isn’t just academic — it’s foundational to reliable PCBA design, manufacturing, and sourcing. Active components bring smart functionality, while passive components provide structural support and signal integrity. For OEM engineers and procurement leaders, partnering with a trusted PCBA expert like HCJMPCBA removes guesswork: we handle sourcing, validation, and delivery so you can focus on building high-performance electronics.

Learn more about PCBA services, contact Guangzhou Huachuang Precision Technology.

Discover what is an 8 layer pcb stackup, best layer configurations, materials, signal integrity stra

What is ipc-tm-650 and how does it help PCB and PCBA teams control quality with consistent, comparab

An unmanned combat aerial vehicle (UCAV) is a military unmanned aircraft designed for combat mission